Condensate system with small water flow seal heater

A technology of condensate water system and heater, applied in lighting and heating equipment, preheating, supplementary water supply, etc., can solve the problems of fine treatment equipment and pipeline leakage, affecting the safe operation of the unit, etc., achieve long service life, reduce cost, Withstands the effect of low water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention, but only as examples, and the advantages of the present invention will become clearer and easier to understand.

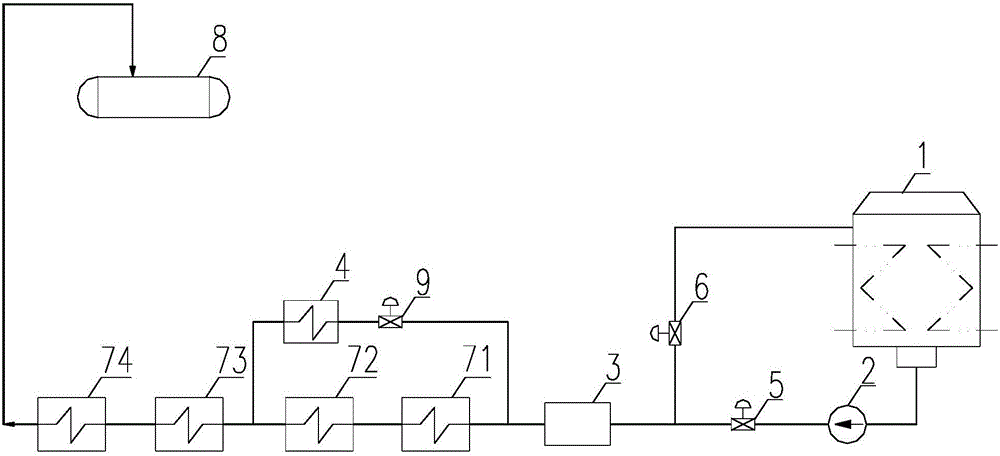

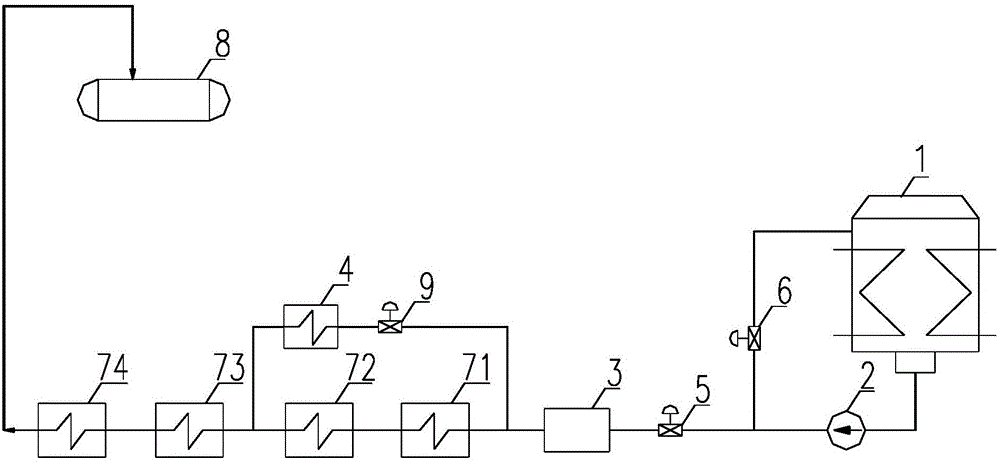

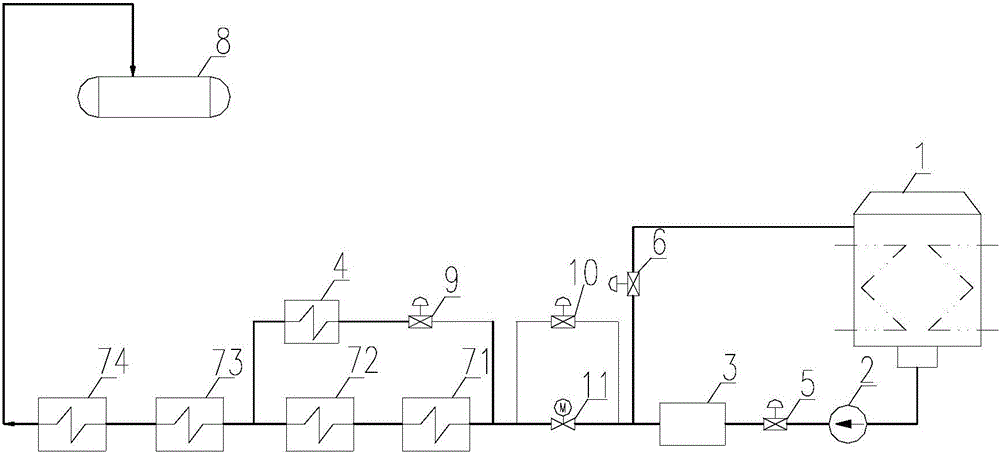

[0024] as attached figure 1As shown, the condensate system with small water flow seal heater is used for the condensate system of the turbogenerator unit, including the condenser 1; The input end is connected; the first output end of the deaerator water level regulating valve 5 is connected with the input end of the condensate polishing device 3; the second output end of the deaerator water level regulating valve 5 passes through the condensate recirculation regulating valve 6 Connect with the recirculation interface of condenser 1;

[0025] The first output end of the condensate polishing device 3 is connected to the input end of the third low pressure h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com