Magnetic and current sensors

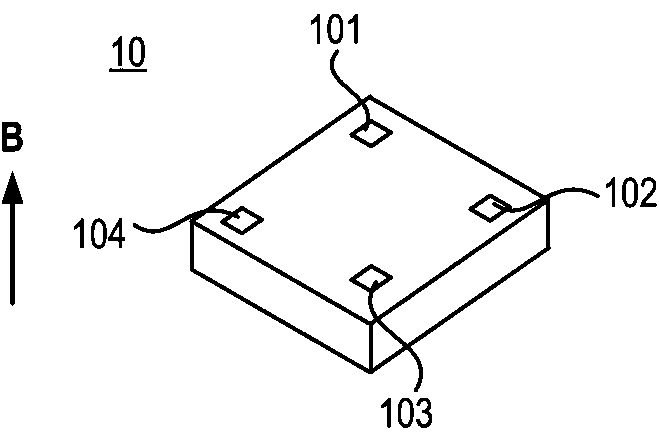

A magnetic sensor and bias current technology, which is applied in the direction of measuring current/voltage, instruments, and measuring electrical variables, etc., can solve the problems of non-uniform offset voltage, inconsistent diffusion thickness, and inability to solve the problem of inconsistent deviation of the diffusion thickness of the magnetic sensitive element 10 , to achieve the effect of reducing the effective signal error and improving the signal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the magnetic sensor and the current sensor provided by the present invention will be described in detail below with reference to the accompanying drawings.

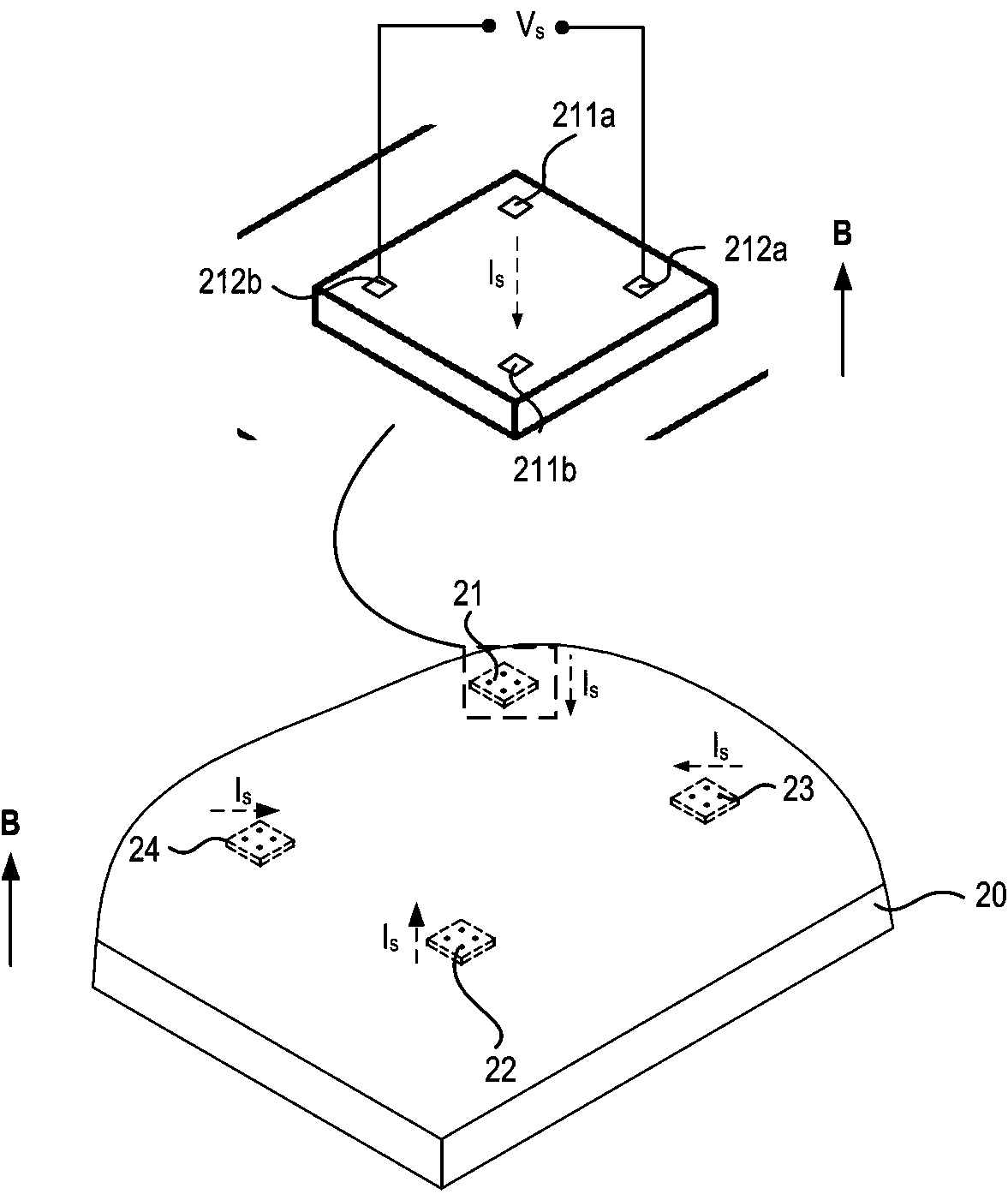

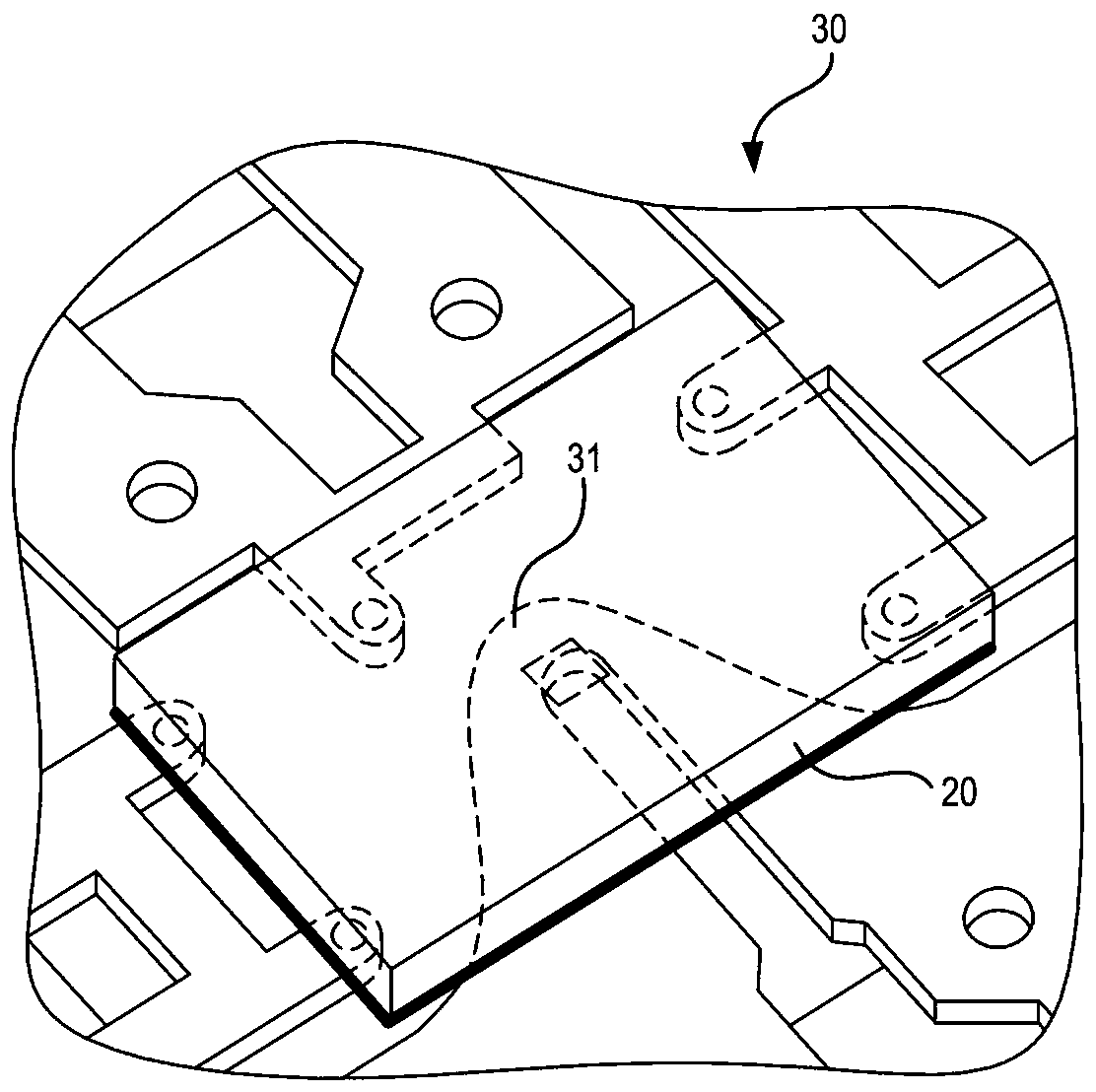

[0015] Attached figure 2 Shown is a schematic diagram of the magnetic sensor structure of the present invention, including a semiconductor substrate 20, a first magnetic sensor 21, a second magnetic sensor 22, a third magnetic sensor 23, and a fourth magnetic sensor on the surface of the semiconductor substrate 20 Sensitive element 24. The first magnetic sensor 21 is provided with a pair of bias electrodes 211a, 211b and a pair of sampling electrodes 212a, 212b. The bias electrodes 211a and 211b have a voltage V s In the case of the magnetic sensor, a bias current I can be introduced s , The sampling electrodes 212a, 212b are used to sample the bias current I s A Hall voltage V generated by working together with an ambient magnetic field B h . Other magneto-sensitive elements are also set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com