Intelligent image positioning intermissive pumping controller

An image positioning and controller technology, which is applied in the program control and electrical program control of the sequence/logic controller, can solve problems such as well jamming and loading, human or animal hazards, and burning motors, so as to ensure production safety High degree of automation, high degree of automation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

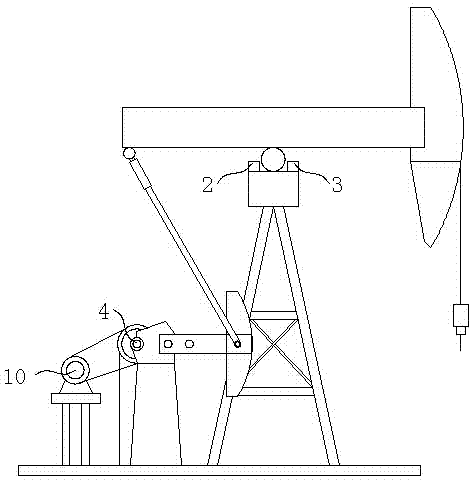

[0019] The following is a further description of the intelligent image positioning and inter-drawing controller of the present invention in conjunction with the accompanying drawings:

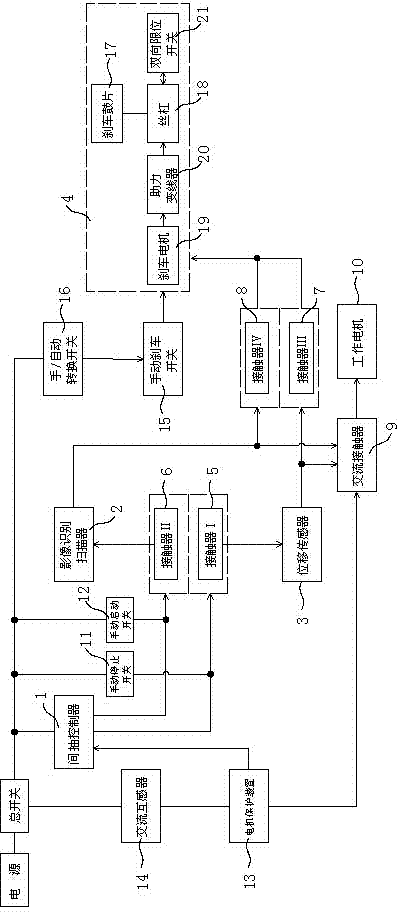

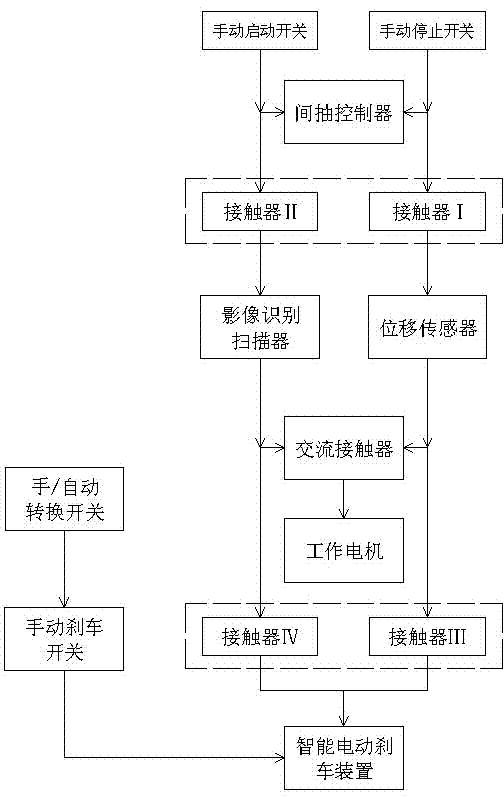

[0020] The intelligent image positioning inter-pumping controller of the present invention is composed of an image recognition scanner 2, a displacement sensor 3 and an intelligent electric brake device 4 on the basis of the inter-pumping controller 1 originally installed on the pumping unit.

[0021] The entire intelligent image positioning inter-pumping controller is connected to the AC power supply, and the circuit connection relationship is as follows: inter-pumping controller 1, contactor Ⅰ5, displacement sensor 3, contactor Ⅲ7 and intelligent electric brake device 4 are sequentially connected in circuit; inter-pumping controller 1 , contactor II6, image recognition scanner 2, contactor IV8 and intelligent electric brake device 4 are circuit-connected in sequence; displacement sensor 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com