Electrodeless control device for blanking

A technology of extreme control and controller, which is applied in the field of stepless control device for blanking, can solve the problem of inability to accurately control the amount of blanking, and achieve the effect of preventing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

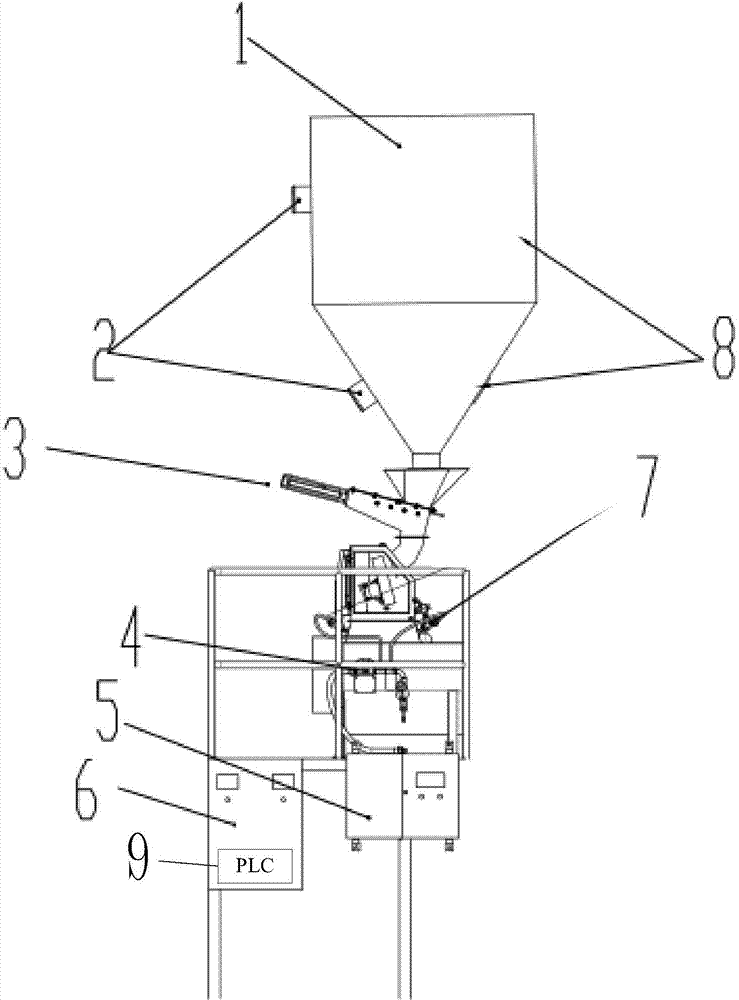

[0038] The invention provides a non-polar control device for blanking to solve the technical problem that the blanking amount in the blanking process cannot be accurately controlled in the prior art.

[0039] The technical solutions in the embodiments of this application are to solve the above-mentioned technical problems, and the general idea is as follows:

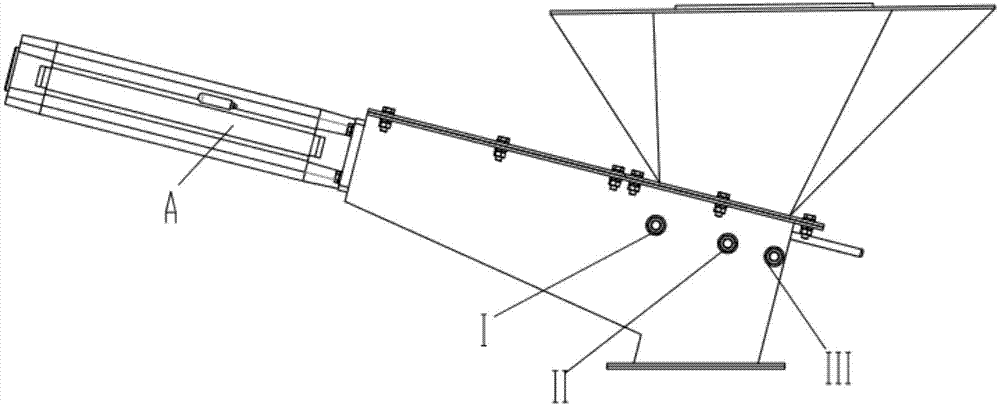

[0040] A stepless control device for unloading is provided, which includes: a finished product warehouse for storing materials; a level gauge arranged on the finished product warehouse for measuring the position of the material; a gate arranged at the discharge port of the finished product warehouse; The weighing chamber is set at the bottom of the gate; the flow meter is set inside the dry flow weighing chamber to detect the material flow in the dry flow weighing chamber; spraying liquid nozzles, the nozzles are aligned with the dry flow weighing chamber, used to mix the liquid with the dry flow weighing chamber The controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com