Silencer pipe joint forming die

A technology for forming molds and pipe joints, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, increased production costs of enterprises, and increased engine exhaust noise, so as to reduce production costs and improve The effect of high production efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

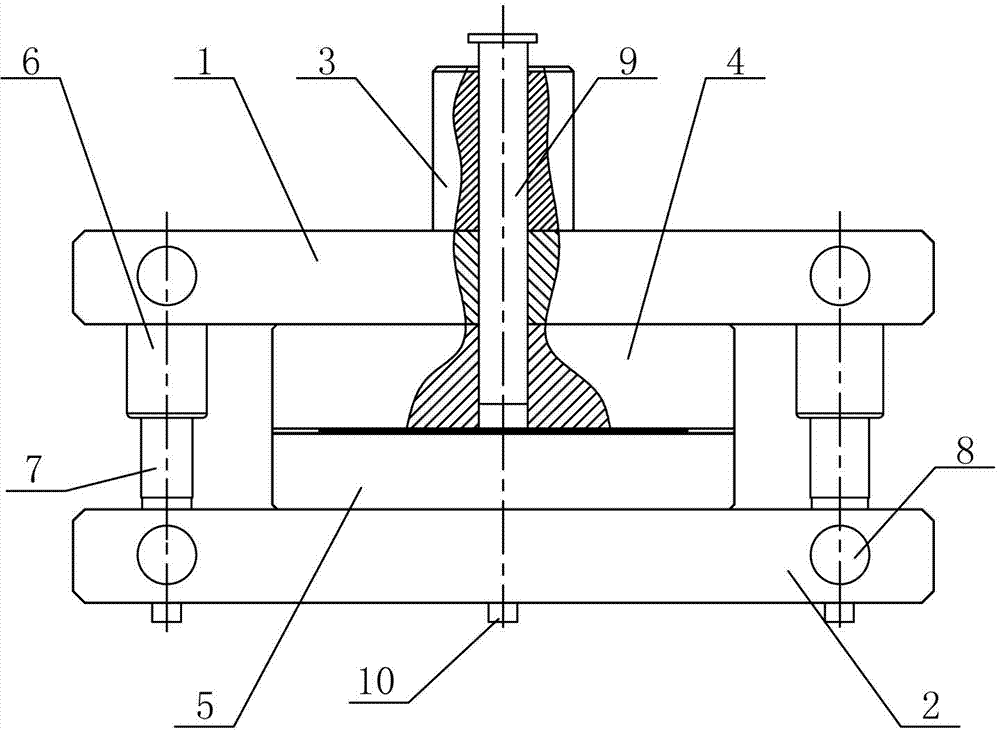

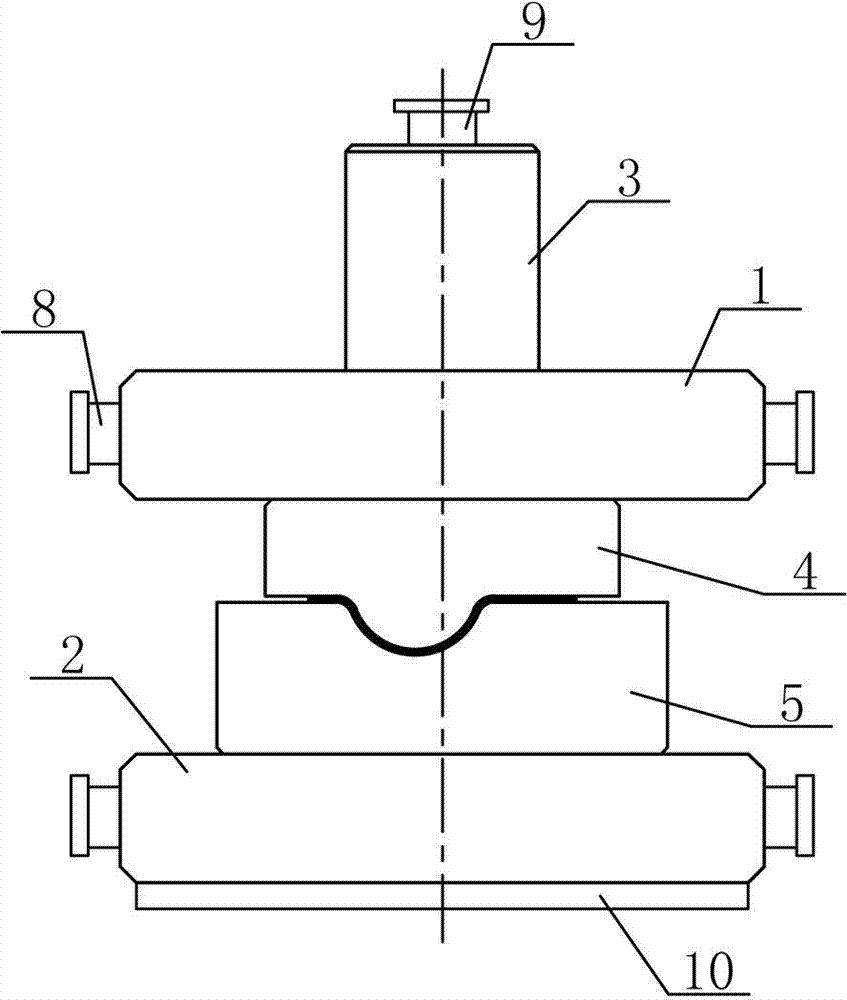

[0013] Such as Figure 1-2 As shown, a muffler pipe joint forming mold described in the embodiment of the present invention includes an upper mold body 1 and a lower mold body 2, a mold handle 3 is provided at the center of the top end of the upper mold body 1, and a protrusion is provided at the center of the bottom end. The die 4 and the center of the lower die body 2 are provided with a die 5, the die 5 corresponds to the punch 4, and two groups of symmetrically distributed guide assemblies are arranged between the upper die body 1 and the lower die body 2, each set The guide assembly includes a guide sleeve 6 and a guide post 7 that are socketed and matched. The diameter of the guide post 7 is smaller than the inner diameter of the guide sleeve 6. The guide post 7 can be inserted into the guide sleeve 6, and the guide sleeve 6 is fixed on the upper mold body 1. The guide post 7 is fixed on the lower mold body 2, and the upper mold body 1 and the lower mold body 2 are provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap