A beam casting method and casting mold with a thin-walled cylinder

A thin-walled cylinder and casting mold technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex external structure, simple internal cavity structure, difficult to meet quality requirements, etc., and achieve easy follow-up processing. , the modeling method is simple, the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

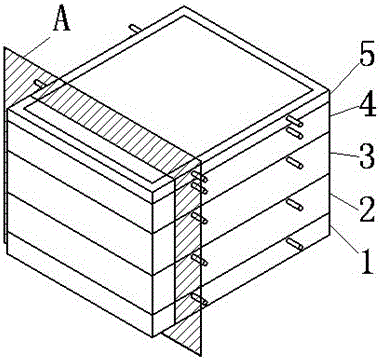

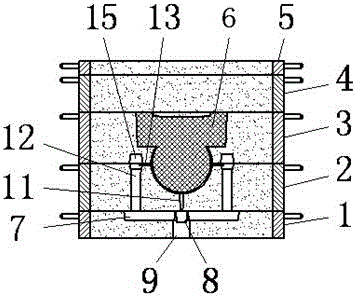

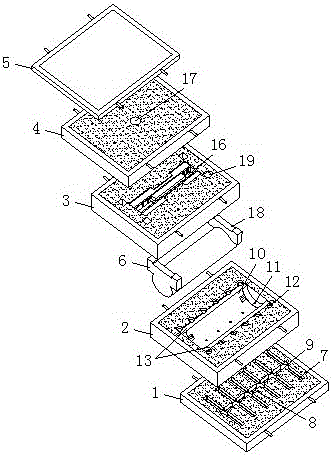

[0023] According to the structural quality requirements of the girder castings, it is determined through analysis that the girder castings are poured horizontally and share five mold boxes: bottom box 1, lower box 2, middle box 3, upper box 4 and cover box 5. The lower box 2, the middle box 3 and the upper box 4 are provided with a mandrel 6. The bottom box 1 is provided with a sprue 9, and the pressure difference pouring method is adopted, and the molten metal is injected from the sprue 9 by pressurization. The bottom box is provided with 6 transverse flow channels 7, and the 6 transverse flow channels 7 are vertically connected by a longitudinal flow channel 8, and a sprue 9 is provided at the intersection of each transverse flow channel 7 and the longitudinal flow channel 8. On the one hand, the molten metal flows into the cavity of the lower box through the inner runner 11 under the action of pressure; The slot runner 13 casts the thin-walled cylindrical body 21 part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com