Method and tool for forming tunnel type hole

A tunnel-type, tool-based technology, which is applied in manufacturing tools, welding equipment, metal processing, etc., can solve the problems of large heat dissipation area, difficult to clean, and low efficiency, and achieve the effect of overcoming low efficiency and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

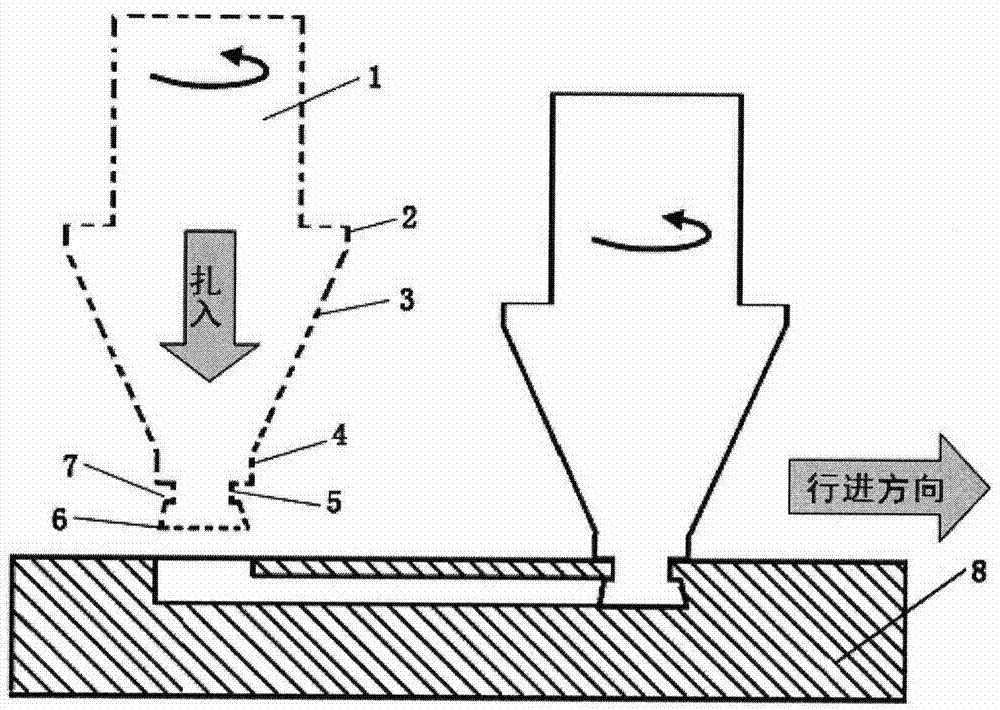

[0014] refer to figure 1 , a tool for preparing a tunnel-shaped hole on a workpiece, the tool is composed of a middle section, a shank 1 and a friction head. One end of the middle section is integrally connected with the handle 1, and the other end of the middle section is integrally connected with the friction head. The middle section is made up of a first cylindrical section 2, a conical section 3 and a second cylindrical section 4, one end of the first cylindrical section 2 is connected with the handle 1 as a whole, and the other end of the first cylindrical section 2 is connected with the conical section 3. One end is connected as a whole, and the other end of the conical section 3 is connected with one end of the friction head as a whole. The rubbing head is composed of a neck 5 and a head 6, the outer diameter of the neck 5 is smaller than that of the head 6, and the cross section of the rubbing head is inverted T-shaped. After the middle section is integrated with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com