Chromatography control method used in low-speed printing process of electronic shaft intaglio printing press

A control method and printing process technology, applied in the field of color register control, can solve the problem of low color register accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

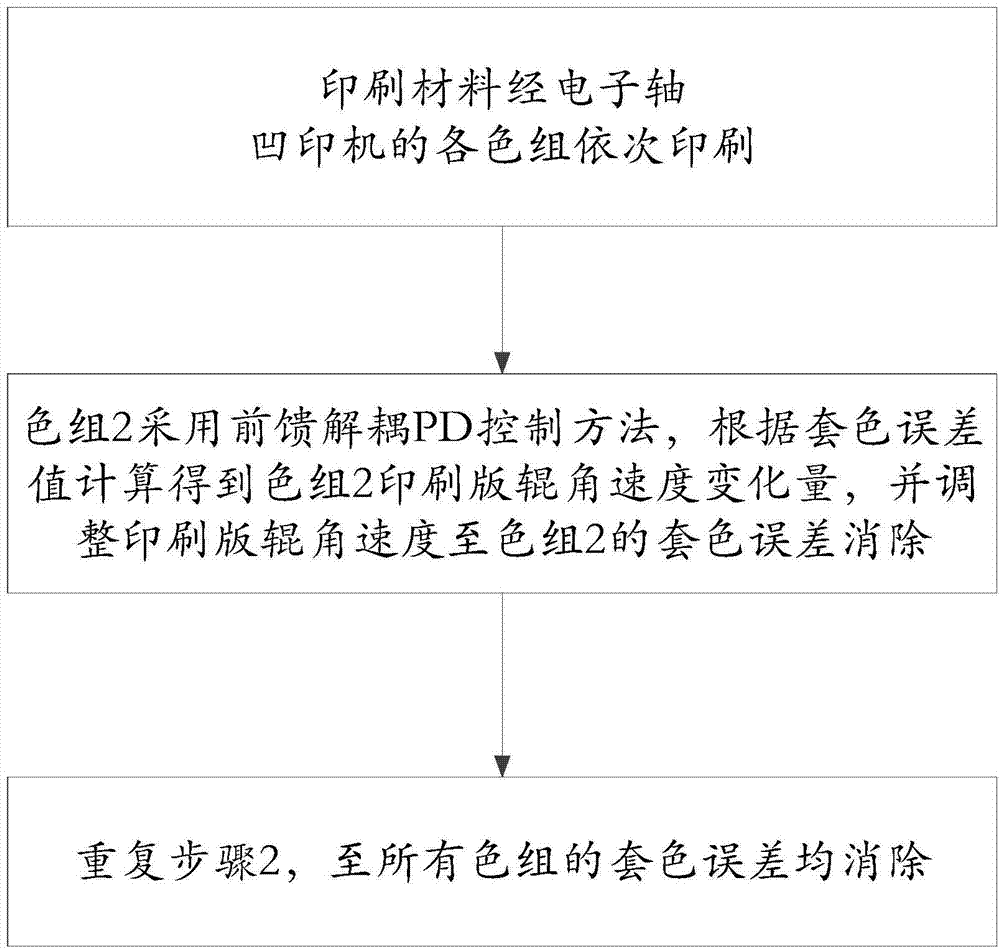

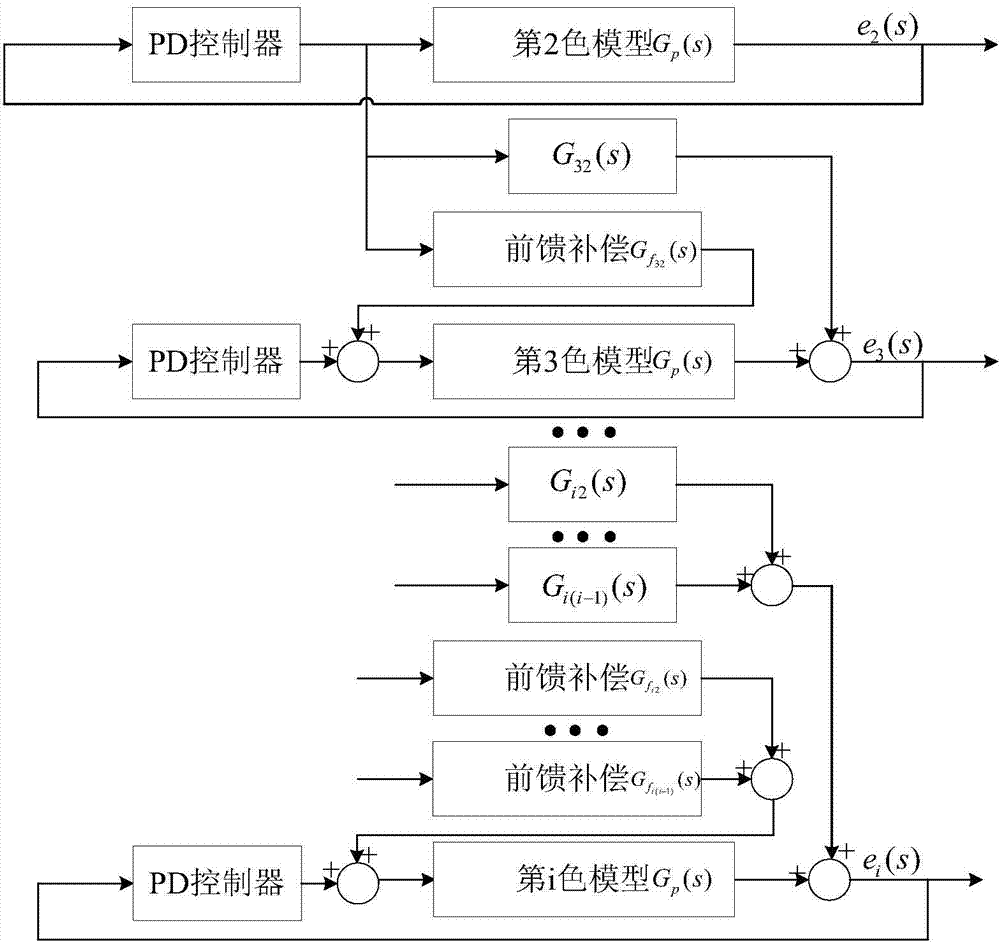

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

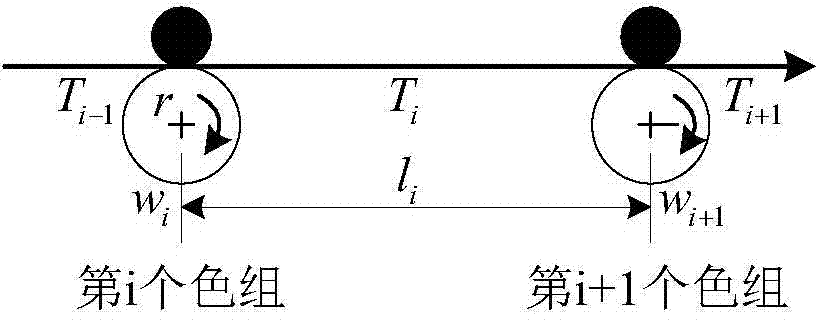

[0037] The control system of the gravure printing machine is composed of two parts: the tension control system and the color register control system. The purpose of tension control is to maintain the tension balance of the rewinding and unwinding part of the printing equipment, so as to avoid the occurrence of printing material wrinkles and being broken, and to lay the foundation for the color registration control of the printing unit; The color registration error caused by it can improve the color registration accuracy and product quality. From the perspective of control objectives, the two control systems are different, but in essence, the core problems they solve are both tension control problems. In the rewindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com