A device for measuring the kiln pressure of a glass melting furnace and a kiln pressure control system using the same

A glass melting furnace and measuring device technology, which is applied in glass manufacturing equipment, glass production, glass furnace equipment and other directions, can solve the problems of inaccurate pressure taking of reference system pipelines and inaccurate pressure measurement values of pressure transmitters. Avoid the interference of airflow on the pressure, take the pressure accurately, and ensure the effect of taking the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

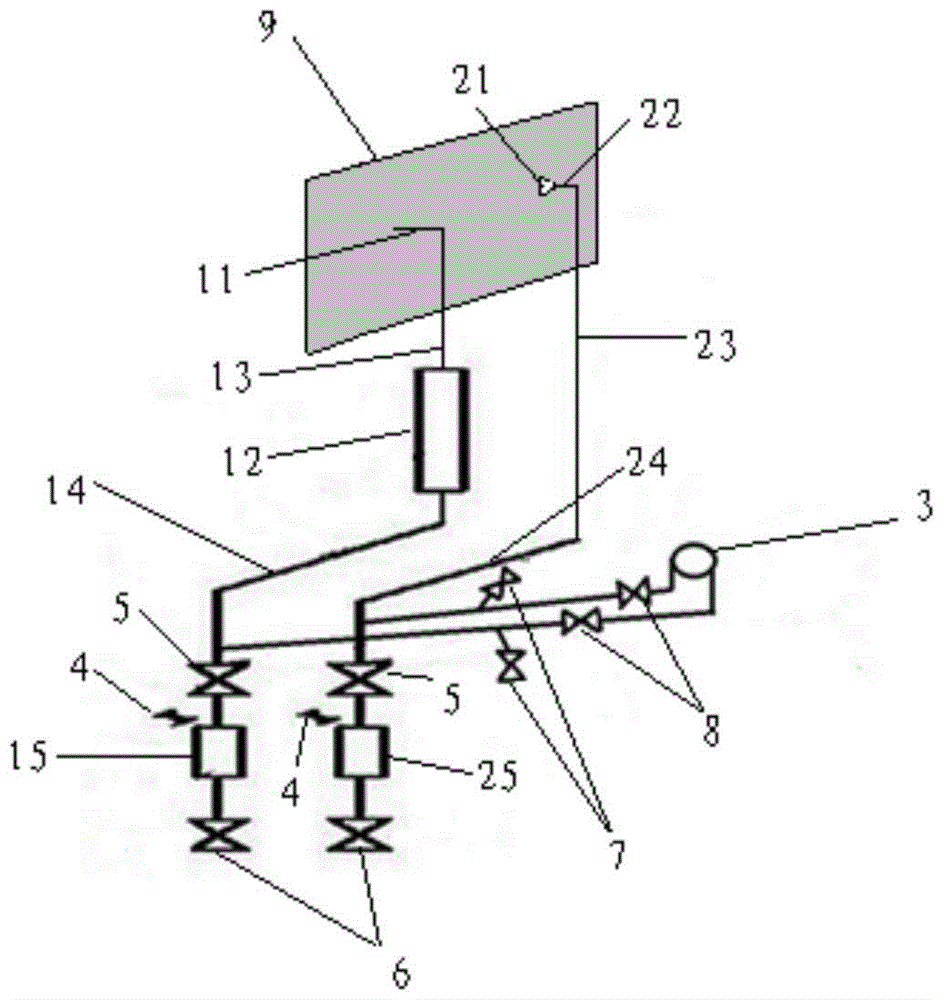

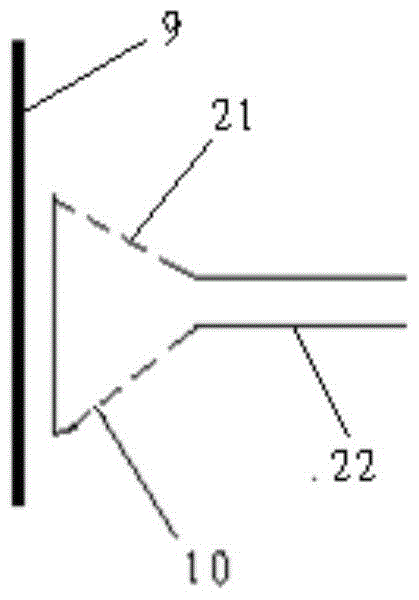

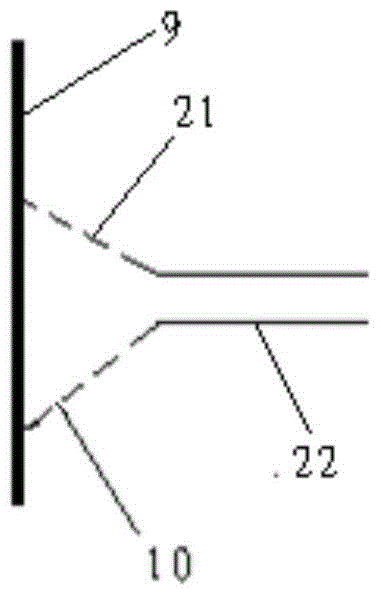

[0033] like figure 1 A furnace pressure measuring device for a glass melting furnace is shown, which includes the internal pressure measuring pipeline of the melting furnace, the external pressure measuring pipeline and the differential pressure measuring pipeline connected with the internal pressure measuring pipeline and the external pressure measuring pipeline respectively. Pressure transmitter 3, wherein, the internal pressure measuring pipeline includes a high-temperature pipe 11 connected to the inside of the glass melting furnace, and the high-temperature pipe 11 is arranged horizontally; the external pressure measuring pipeline includes receiving the external pressure of the melting furnace The receiving device 21 of the airflow, such as figure 2 As shown, the receiving device 21 has a receiving tube with a large mouth end and a small mouth end, the large mouth end of the receiving tube is closed, the small mouth end of the receiving tube communicates with the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com