Wide-angle Y-shaped pier column construction method

A construction method and large-angle technology, applied in the direction of bridge parts, erection/assembly of bridges, bridge materials, etc., to achieve the effect of ensuring structural safety and construction safety, reducing installation and material costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

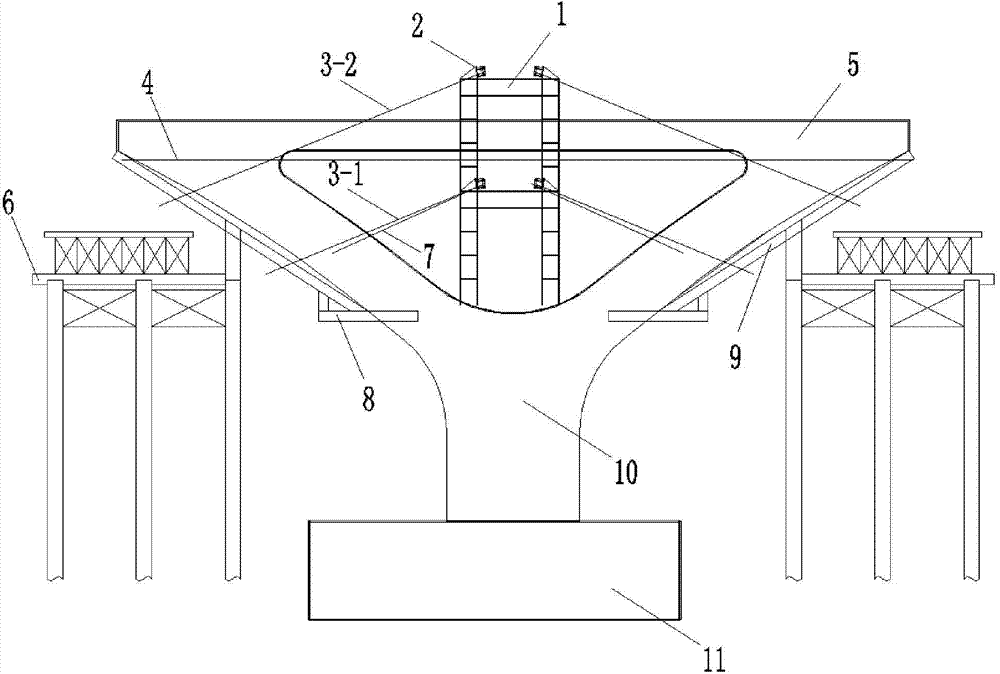

[0040] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

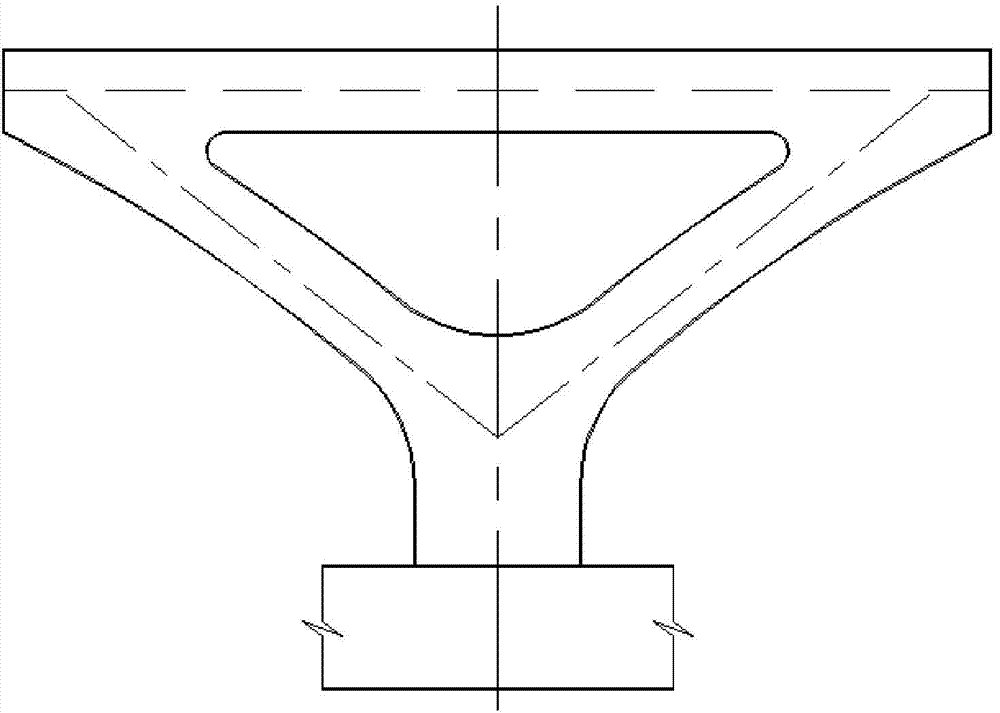

[0041] The invention provides a construction method of a large-angle Y-shaped pier column. The construction method is mainly applicable to a Y-shaped pier column whose included angle between the legs of the "V"-shaped two oblique limbs of the pier column 10 pier body is greater than 90°. This large-angle Y-shaped pier column cannot be self-contained before the prestressed tension of the upper tie beam 5, and must rely on strong external support.

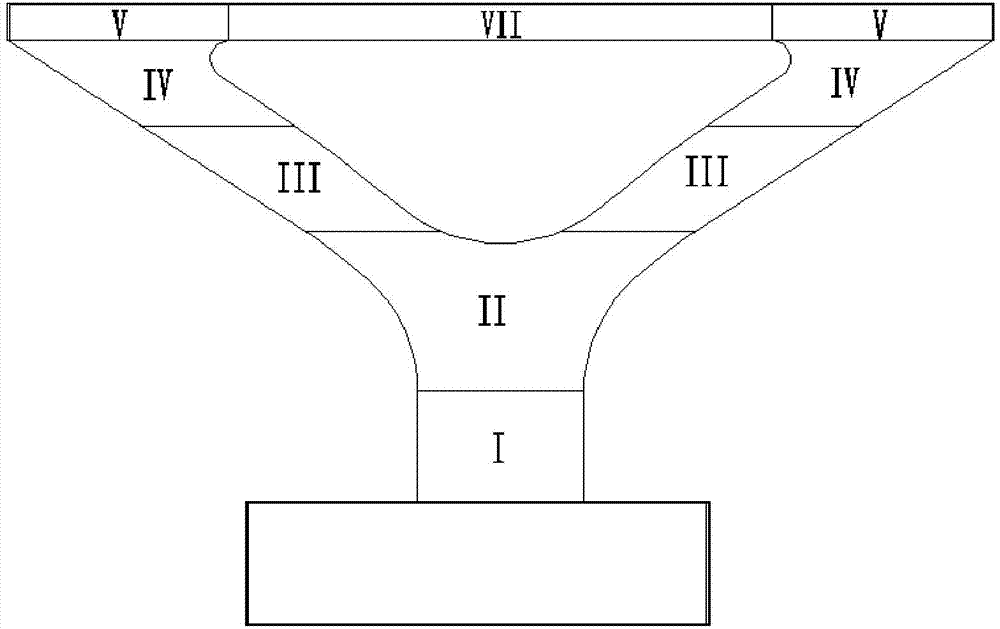

[0042] The Y-shaped pier column can be regarded as including a straight line section, a coupling section transitioning from a straight line section to a slanted leg section, a slanted leg section, and a tie beam 5 according to different cross-sectional shapes from bottom to top. The Y-shaped pier co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com