Electric hydraulic multifunctional grab bucket

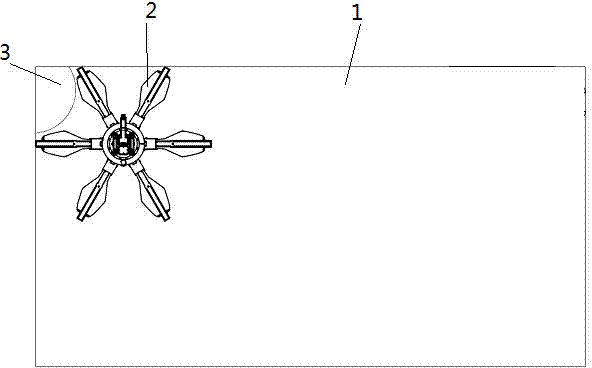

A multi-functional, hydraulic technology, applied in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc., it can solve the problem of inability to grab the garbage in the garbage pond and the leachate at the bottom of the garbage pond cannot be cleaned out. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

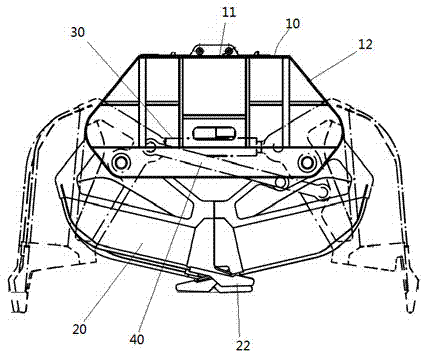

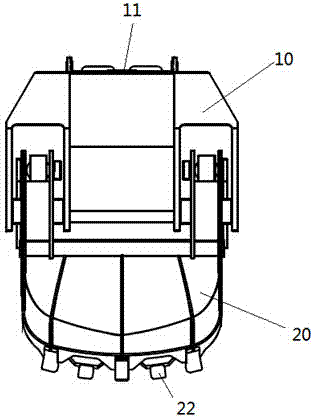

[0021] see figure 2 , 3 , 4. The electro-hydraulic multifunctional grab mainly includes an upper bolster 10, a hydraulic system, a double-lobe bucket body 20, and a horizontal oil cylinder 30 for driving the double-lobe bucket body to move.

[0022] The upper bolster 10 is a sealed box-type upper bolster, and a sealing plate 11 is arranged on the top of the upper bolster, and side plates 12 are respectively arranged on the left and right sides, and the front and rear sides of the upper bolster; the hydraulic system (not shown in the figure) It is installed inside the sealed box-type upper bolster to ensure that the grab can work normally under 5 meters of water. The detachable connection between the sealing plate 11 and the upper bolster 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com