Packer in recycling oil well air drill

A technology of packer and oil well gas, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc. It can solve the problems that the packer and connecting pipe string are not easy to recover, and achieve saving operation time, strong operability and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

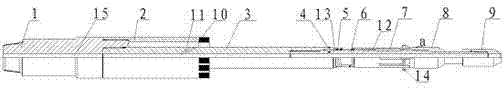

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0015] A device for recovering the packer in oil well gas drilling according to the present invention, as shown in the figure: includes an upper joint 1, a milling barrel 2 is connected to the lower end of the upper joint 1 through an external thread, and a milling barrel 2 is arranged at the lower end of the milling barrel 2. The milling device 10, the lower end of the upper joint 1 is connected with the connecting rod 3 through an internal thread, and the connecting rod 3 is provided with a water eye hole 11, the position of the water eye hole 11 corresponds to the position of the milling device 10, and the spear rod of the boss 12 is provided 6 is threadedly connected to the lower end of the connecting rod 3 and is provided with a fastening screw 4, the washer 13, the spring 5 and the slip 7 provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com