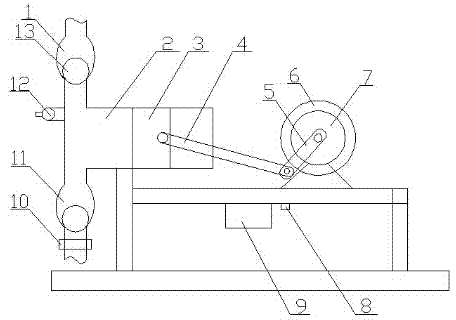

Foam concrete conveying device

A technology of foam concrete and conveying devices, which is applied to the components of pumping devices for elastic fluids, liquid variable capacity machinery, pump control, etc., and can solve problems such as layering of conveying materials, limited conveying height, solid drums, etc. To achieve the effect of compact structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

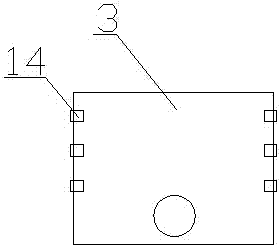

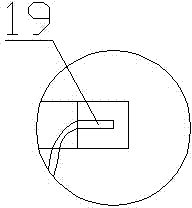

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the superiority of this device, the performance of this device is tested with different data:

[0029] The first group: Different pump bodies with the same power were used for the same slurry, and their pressure, single use cycle, power per unit time, height and horizontal distance were tested respectively. The experimental data obtained are shown in the following table:

[0030] .

[0031] Note: The same slurry is pure foam concrete slurry, and can also be other fine materials, slurry, etc.

[0032] It can be seen from the above table that the pump body with the same power can transport the same slurry, the conveying height and conveying distance of this device are far higher than those of diaphragm pumps and hose pumps, and its power per unit time has reached 50 cubic meters Per hour, far greater than the power per unit time of diaphragm pumps and hose pumps; it can be seen from the table that the device can reach 8,000 cubic meters i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com