Water source heat pump device for making hot water within non-heating full-load time

A water-source heat pump, full-load technology, applied in the field of water-source heat pumps, can solve the problems of producing hot water, reducing the economical practicability of equipment, and reducing user comfort, saving operating costs, improving economic practicability, and improving user comfort. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

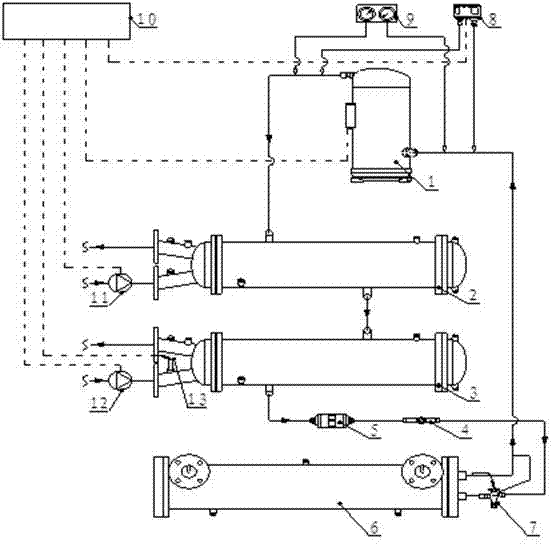

[0012] Such as figure 1 As shown: the water source heat pump device described in this embodiment to produce hot water during the non-heating full-load time is mainly composed of a compressor 1, a heat recovery device 2, a water-cooled condenser 3, a sight glass 4, a drying On the basis of the structure of the water source heat pump heat recovery unit composed of filter 5, water-cooled evaporator 6, thermal expansion valve 7, high-low pressure controller 8 and high-low pressure gauge 9, a device for detecting air-conditioning water is installed on the water inlet of water-cooled condenser 3. return water temperature, and feed back the temperature signal to the temperature sensor 13 of the general controller (known products, generally use thermocouples, any other type of sensor that can sense and transmit temperature signals can be used), and enter the water-cooled condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com