Multistation multi-row tail-end-free integrated centralized heating network

A central heating and heating pipe network technology, applied in hot water central heating systems, household heating, heating systems, etc., can solve problems such as temperature imbalance in heating areas, reduce heating costs, etc., and achieve temperature resolution Imbalance, reduce investment and operating costs, increase the effect of water temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

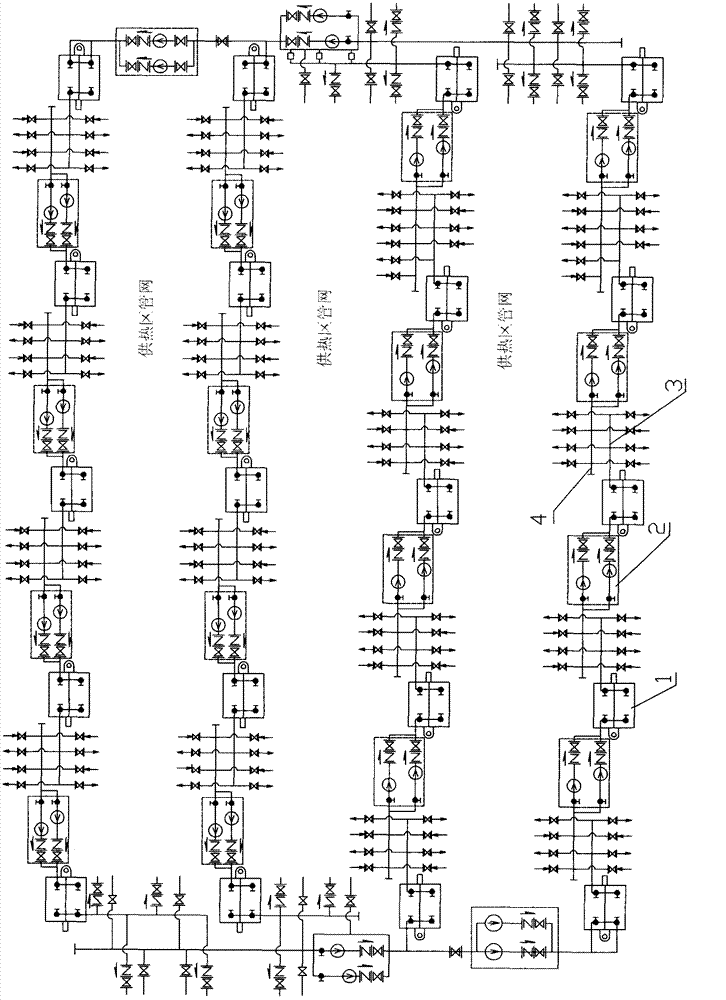

[0013] Referring to the accompanying drawings, the multi-station, multi-row and endless integrated central heating network of the present invention includes several groups of heating boilers 1 and pressurized circulation equipment 2 matched therewith. Each heating boiler 1 and pressurized circulation equipment 2 form several multi-site heat supply sources. The water outlet of the heating boiler 1 is connected to the water outlet pipe 3 of the heating pipe network. The water return port of each pressurized circulation device 2 is connected with the return water pipe 4 of the heating pipe network. The outlet pipes 3 of the heating pipe network and the return water pipes 4 of the heating pipe network are arranged in multiple rows, and each heat supply source is connected in series according to a corresponding distance. The water outlet pipe 3 of the heating pipe network and the return water pipe 4 of the heating pipe network are provided with several pairs of water outlets and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com