Strength check method for asphalt pavement

A technology of asphalt pavement and strength checking, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems that the resistance of asphalt mixture cannot be objectively characterized, the structural resistance cannot be truly reflected, and the pavement damage characteristics cannot be objectively reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

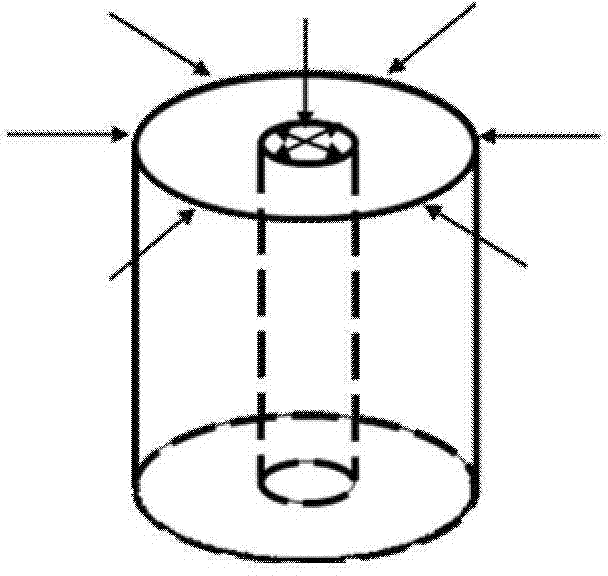

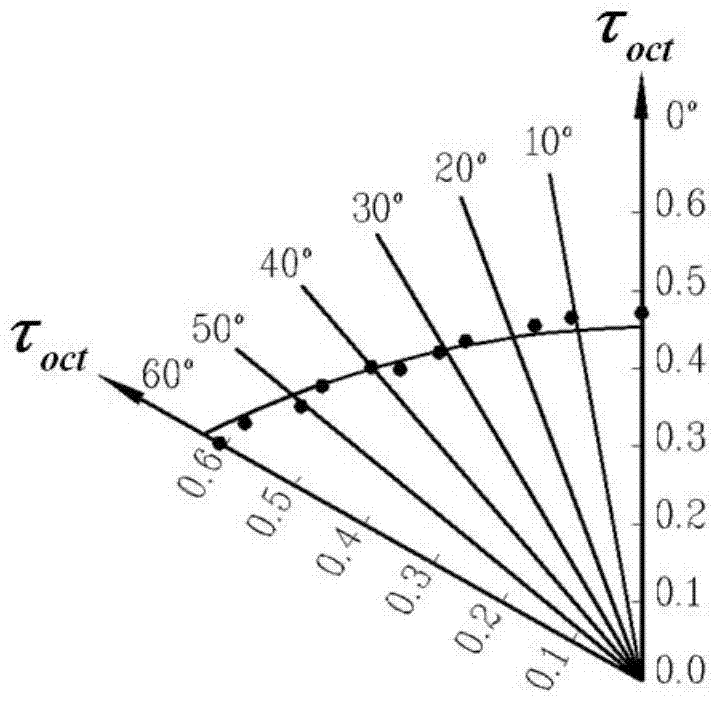

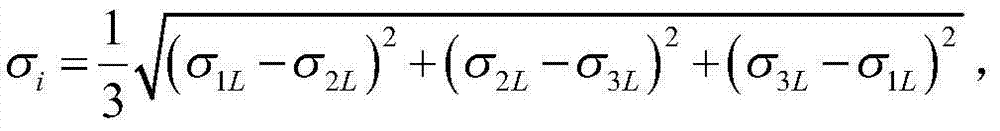

[0040] Step a. Carry out mechanical analysis on the typical asphalt pavement structure. According to the regulations in the highway asphalt pavement design specification, use the multi-layer elastic continuous system theory under the action of double-circle vertical uniform load to calculate the mechanical response of the pavement structure, and obtain the asphalt pavement hazard Principal stress σ at point 1L, σ 2L , σ 3L Respectively -0.278MPa, -0.443MPa, -0.682MPa; according to σ i = 1 3 ( σ 1 L - σ 2 L ) 2 + ( σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com