Experimental device for simulating corrosion in crude oil pipeline

A technology for simulating experimental devices and corrosion experiments, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of reduced transmission efficiency, pipeline leakage, pipeline stoppage, etc., and achieve convenient operation and temperature control Broad, temperature control and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

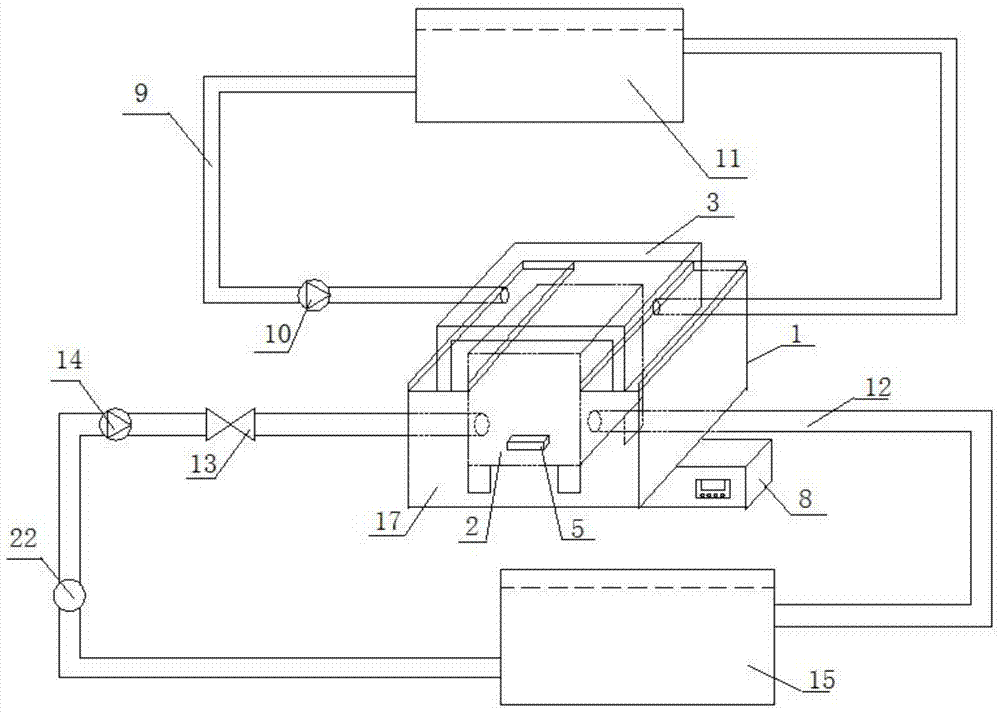

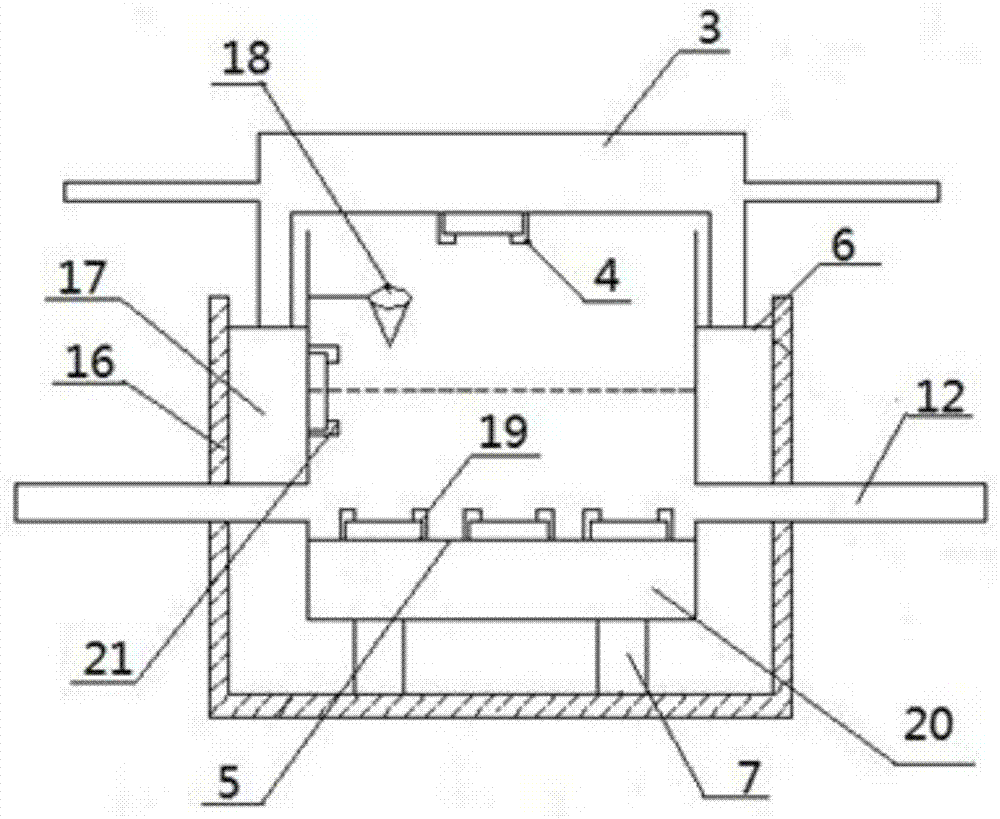

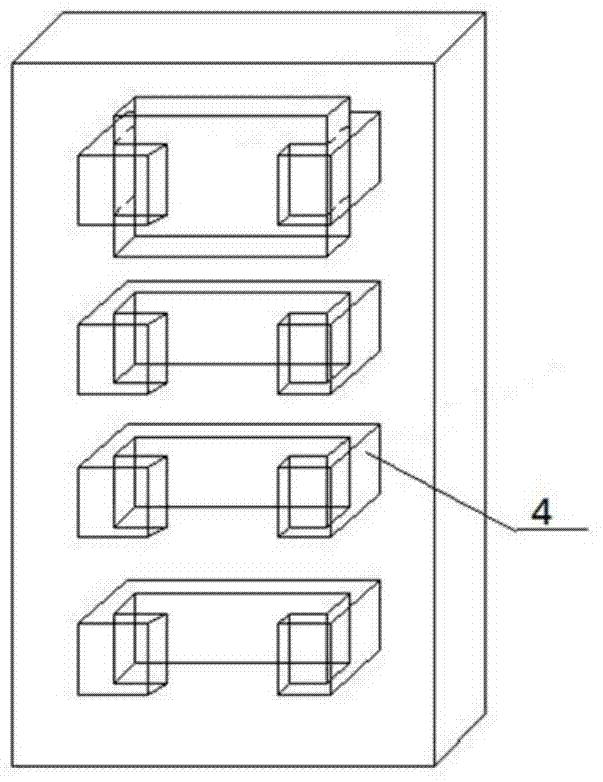

[0029] Such as figure 1 As shown, a crude oil pipeline internal corrosion simulation experiment device includes a temperature-controlled water bath box 1, a corrosion test box 2, a condensate water tank 3, a condensate water pipe 9, a water storage tank 11, an oil delivery pipe 12 and an oil storage tank 15. Both the temperature control water bath 1 and the corrosion test box 2 have no top cover structure, and the corrosion test box 2 is located inside the temperature control water bath 1; the condensed water tank 3 is located in the temperature control water bath 1 and the corrosion test box 2 The upper part of the top constitutes a top cover, and the temperature control water bath box 1, the corrosion test box 2 and the condensation water box 3 form an openable sealed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com