Imbibition and extraction device and imbibition and extraction experimental method

A technology of extraction device and experimental method, applied in measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of wall hanging, imbibition extraction process cannot be directly observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

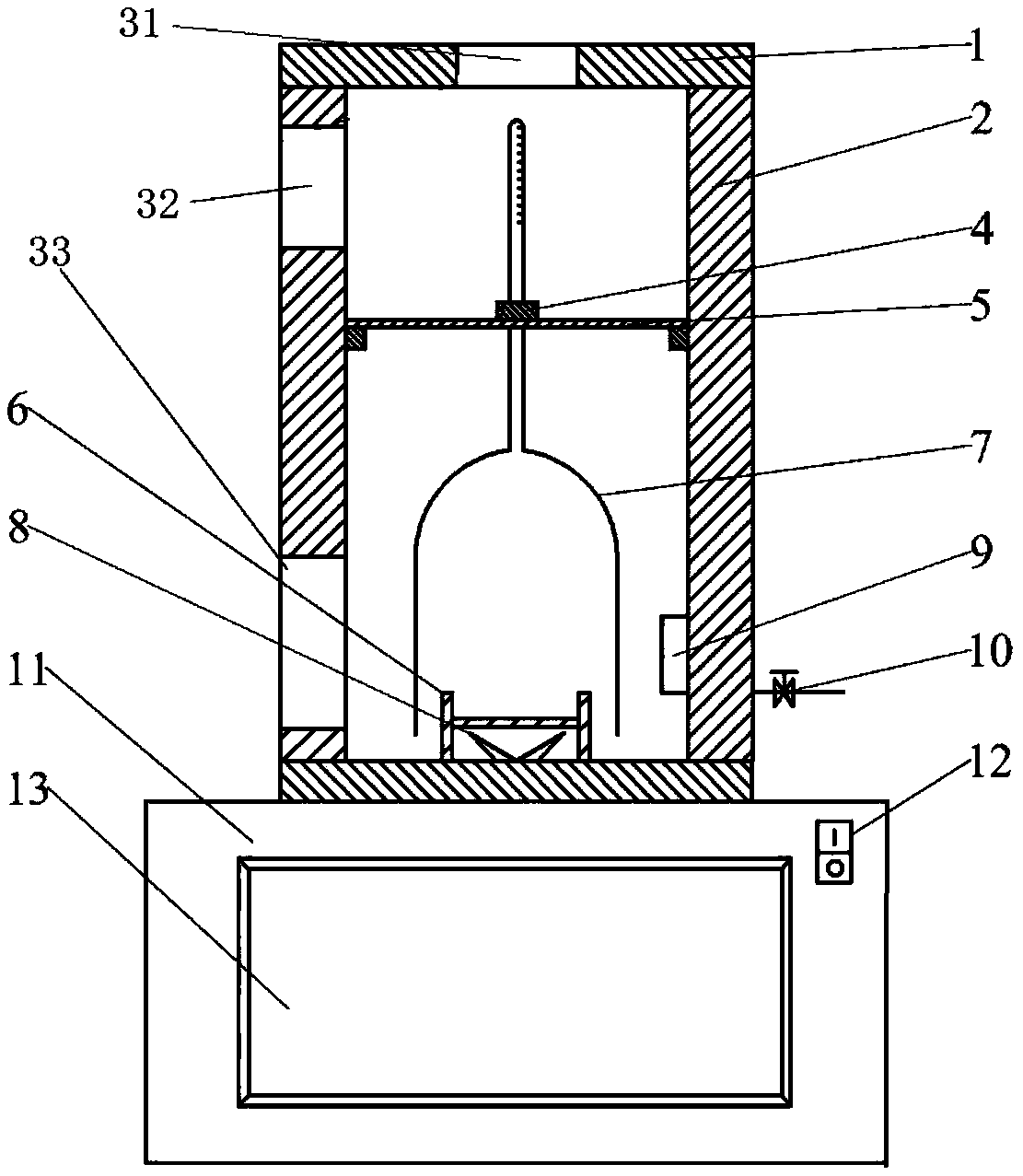

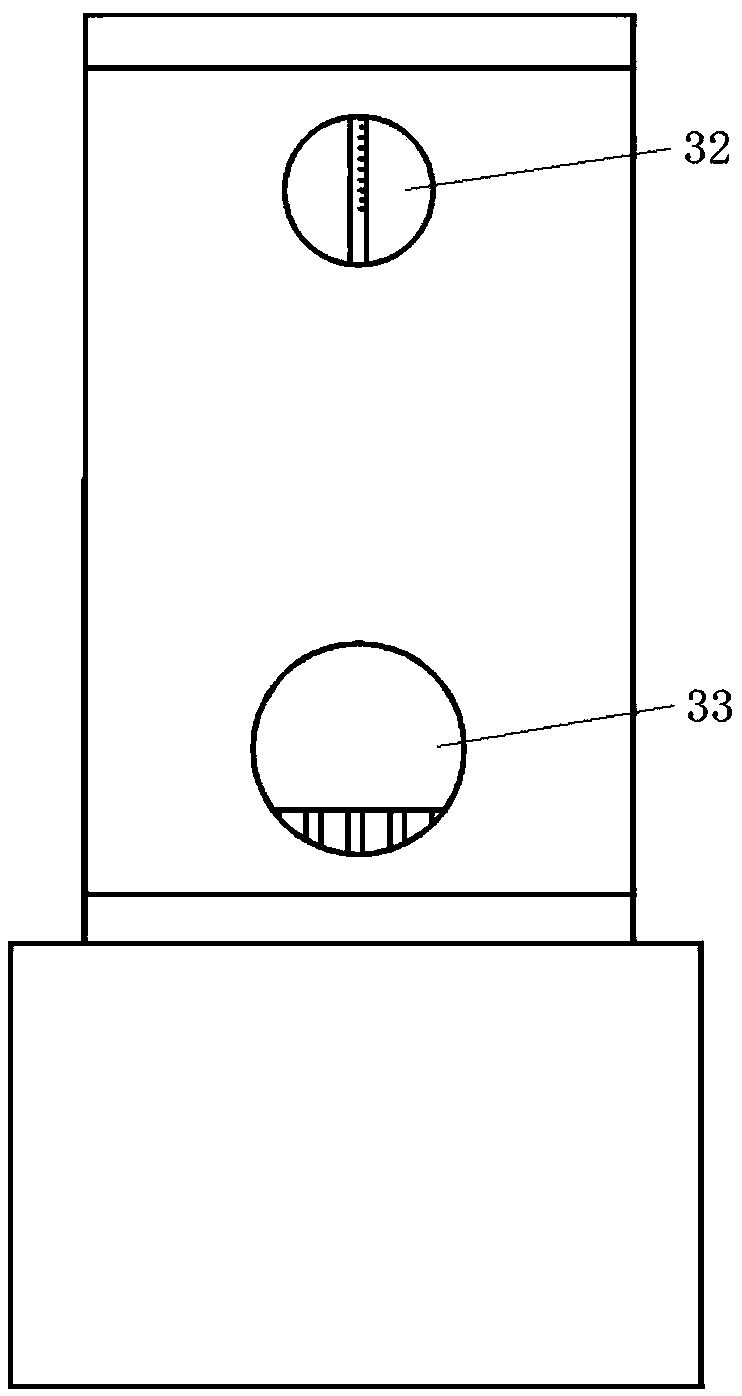

[0057] When using the visualized high-temperature and high-pressure imbibition extraction device of the present invention to carry out the imbibtion experiment, the imbibition device is placed vertically, and the high-temperature-resistant autoclave body is installed on the base, and the core saturated crude oil to be measured is aged for a period of time and placed On the clamping piece in the siphon bottle, and fix the clamping piece in the kettle body, the clamping piece is very stable through the fixed lock at the bottom of the kettle body, it will not rotate with the rotation of the fluid, but is fixed Motionless. The clamping piece can be adjusted axially and vertically according to the size of the core, and can hold It is a cylindrical core of 25-40mm. The clamping part is completely submerged in the experimental liquid. During the seepage process, the magnetic stirring device can be adjusted according to the experimental needs to make the rotor rotate, and then drive...

Embodiment 2

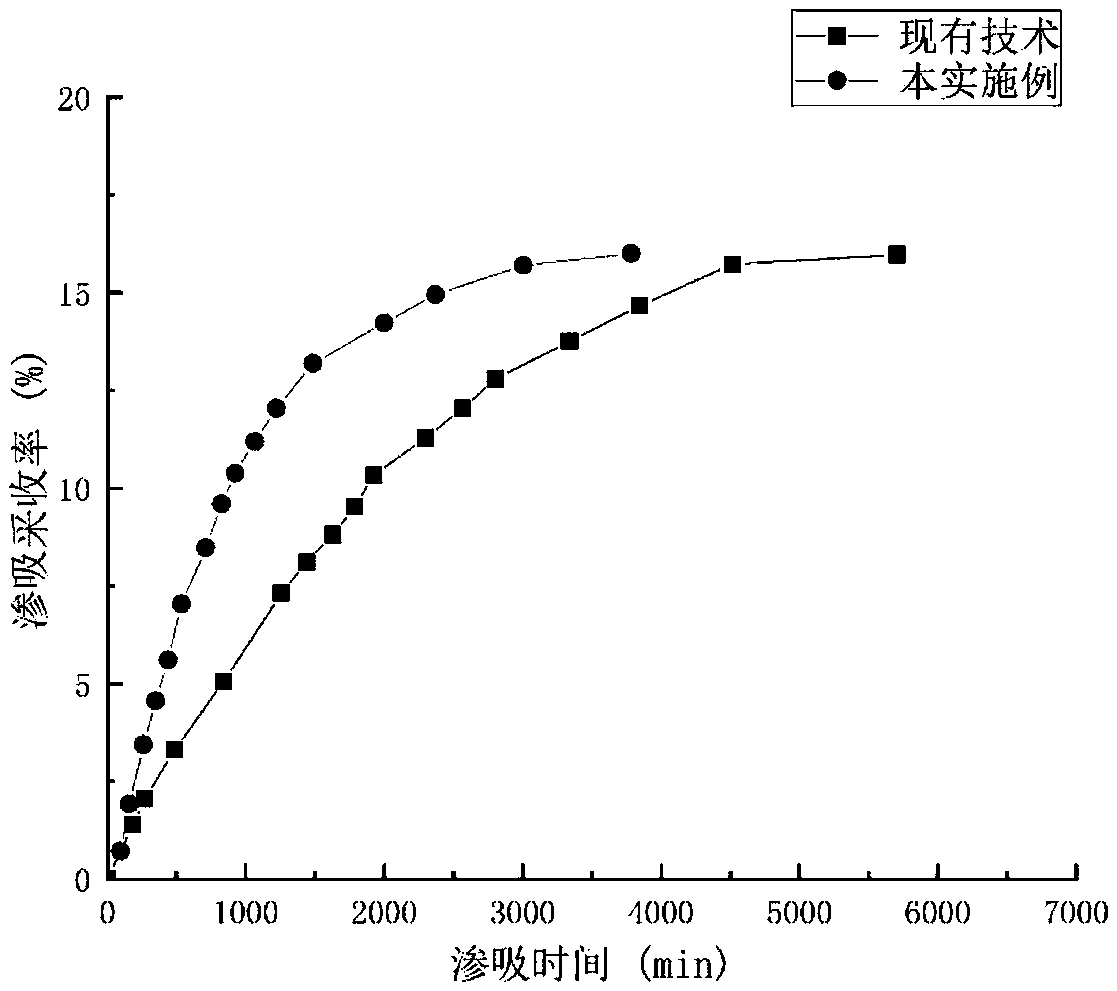

[0060] In order to explore whether the increase of the near-wall flow velocity has an effect on the imbibition process after the fluid in the kettle rotates, the experiment was designed according to the similar model, and the experiment of measuring the near-wall pressure was carried out by using a stainless steel core model with a pressure sensor on the peripheral wall. Jointly study the effect of increasing near-wall flow velocity on near-wall pressure. Table 1 lists the experimental results and numerical simulation results of the pressure near the wall of the simulated core wall pressure measuring point 1 and measuring point 2. Fig. 4(1) is the pressure distribution diagram of the experiment, and Fig. 4(2) is the numerical simulation Pressure distribution diagram.

[0061] Table 1 Comparison of experimental results and numerical simulation results of simulated core measurement of near-wall pressure

[0062]

[0063] From Table 1 and Figure 4(1) and Figure 4(2), it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com