Three-hole rock core kettle and ultra-low-permeability reservoir fluid damage evaluation test apparatus and method

An experimental method and technology of experimental device, applied in measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not considering osmotic pressure, high displacement pressure difference, long flow rate stabilization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

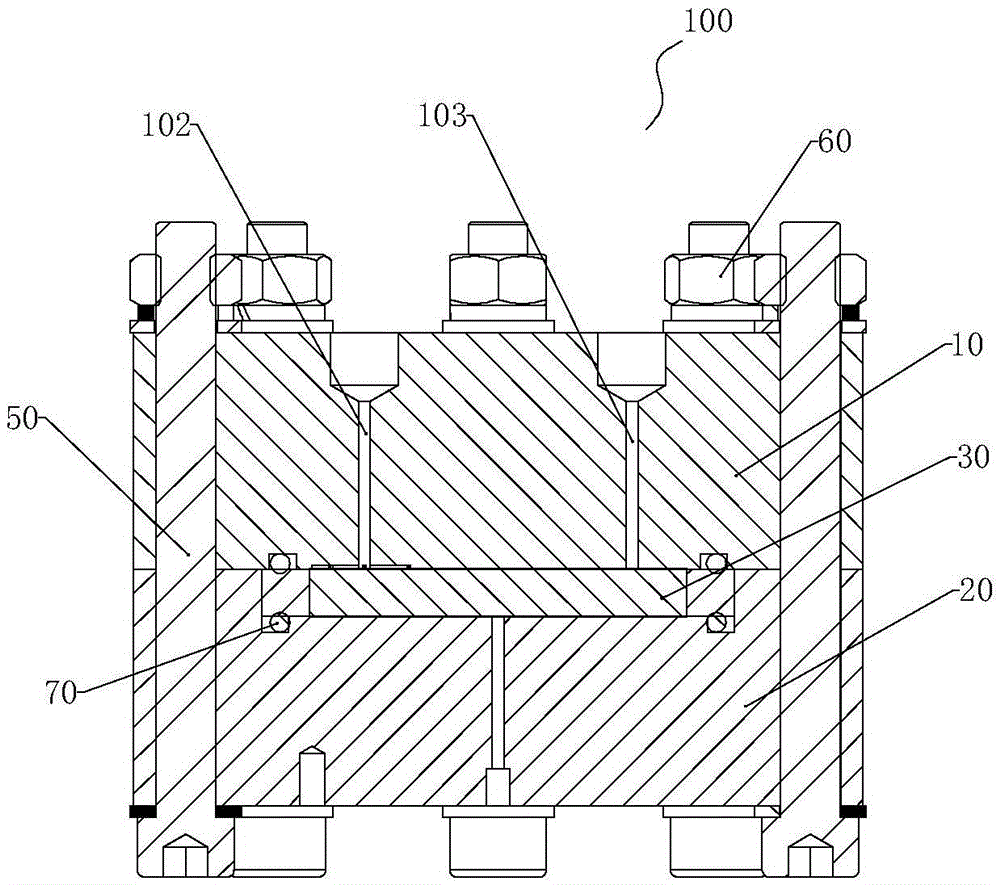

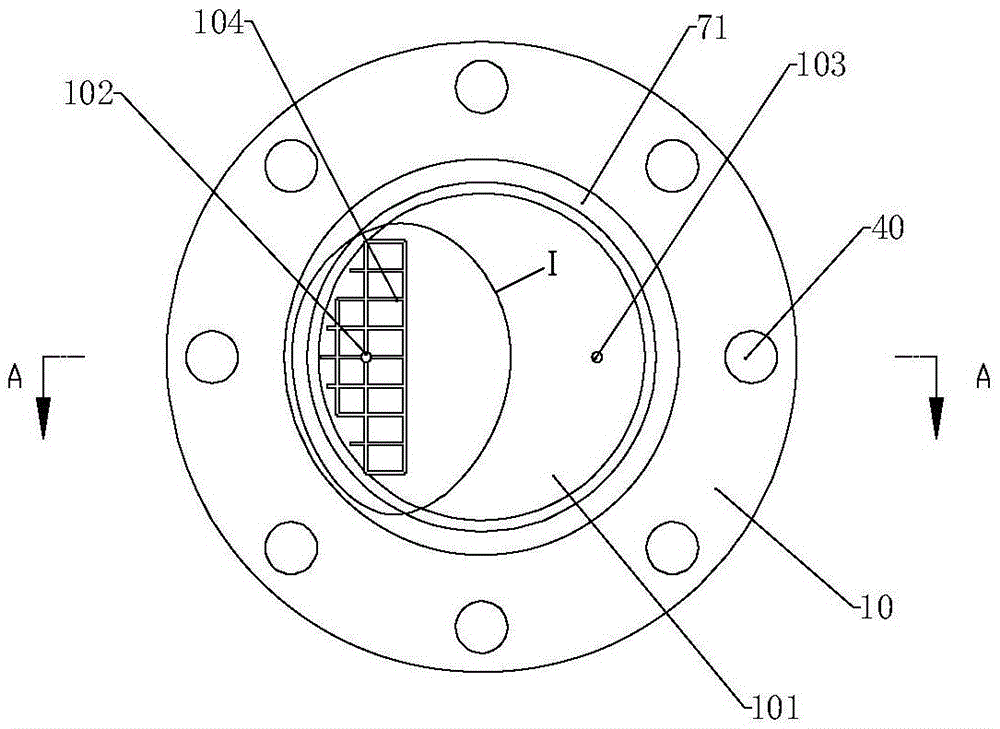

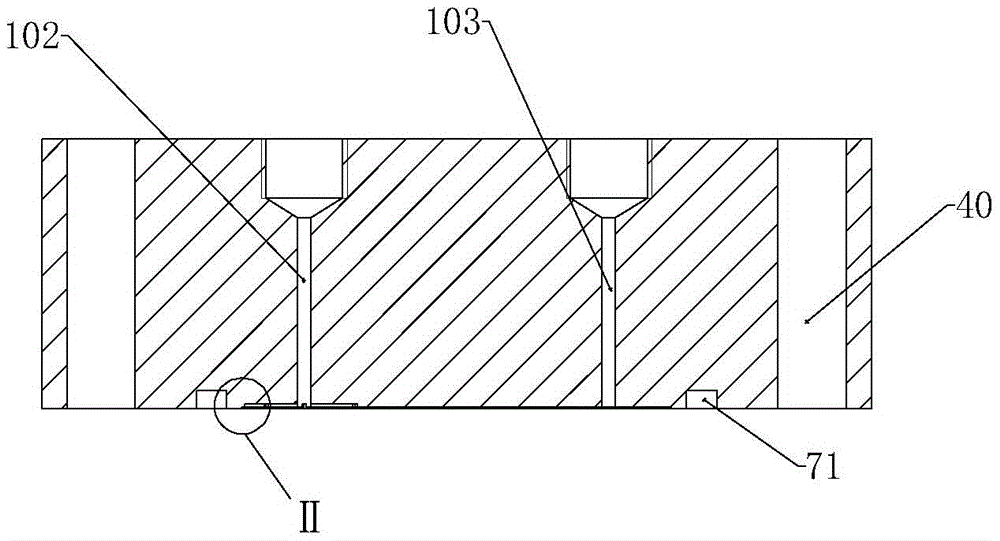

[0070] like figure 1 As shown, the present invention provides a three-hole core kettle 100 for holding a core sample therein for experiments. The three-hole core kettle 100 includes an upper cover 10 , a lower cover 20 , and a core sample 30 . The upper cover body 10 is a cylinder made of stainless steel, the diameter of the upper cover body 10 is 3.86 inches, and the thickness is 1.25 inches. like figure 2 , image 3 , Figure 4 and Figure 5 As shown, the lower end surface of the upper cover body 10 is provided with a circular first groove 101, the first groove 101 is located in the middle position of the upper cover body 10, and the upper cover body 10 is provided with a first concave groove through its upper end surface. The first through hole 102 and the second through hole 103 of the groove 101 . The first through hole 102 and the second through hole 103 can be formed by drilling the upper cover body 10 , and the diameter of the first through hole 102 and the secon...

Embodiment 2

[0077] The present invention also provides an ultra-low permeability reservoir fluid damage evaluation experimental device 1000 using the three-hole core kettle 100, such as Figure 11 As shown, the experimental device 1000 includes a three-hole core tank 100 , an intermediate container 200 for the upstream simulated formation fluid, an intermediate container 300 for the downstream simulated formation fluid, and an intermediate container 400 for the liquid to be tested.

[0078]The first end of the upstream simulated formation fluid intermediate container 200 and the first end of the downstream simulated formation fluid intermediate container 300 are respectively connected to the plunger pump 500 through pipelines, and the first end of the upstream simulated formation fluid intermediate container 200 is connected to the plunger pump 500 The pipeline between them is provided with a control valve a1; the pipeline between the first end of the downstream simulated formation fluid i...

Embodiment 3

[0086] A certain area in my country is rich in shale gas resources, and the shale reservoir matrix is dense, which is a typical ultra-low permeability reservoir. The development of shale gas resources requires large-scale hydraulic fracturing operations to transform the reservoir. In order to form complex The volume fracture network is proposed to use slick water fracturing fluid system. In order to test the damage degree of the fracturing fluid to the shale reservoir in the area, the present invention also provides an experimental method using the above-mentioned experimental device 1000, the experimental method comprising:

[0087] S1, prepare a core sample 30 with a diameter of 2.5 inches and a thickness of 0.25 inches, and prepare a simulated formation fluid with the same activity as the original interstitial fluid.

[0088] S2, put the prepared core sample 30 into the three-hole core kettle 100, and connect all components through pipelines. Connect the pipelines between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com