Nailboard Drawing Generation Method for Electrical Wiring Harness Manufacturing

A wiring harness and nailboard diagram technology, applied in the field of nailboard diagram generation, can solve problems such as inappropriateness, achieve the effects of improving production efficiency, shortening production cycle, and reducing wiring error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

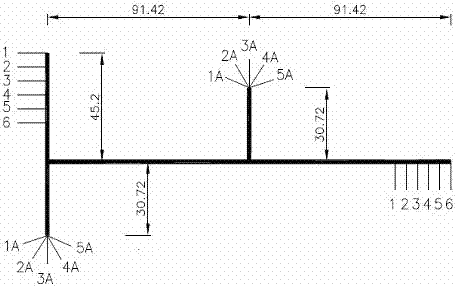

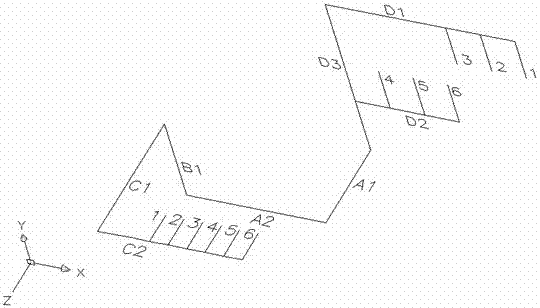

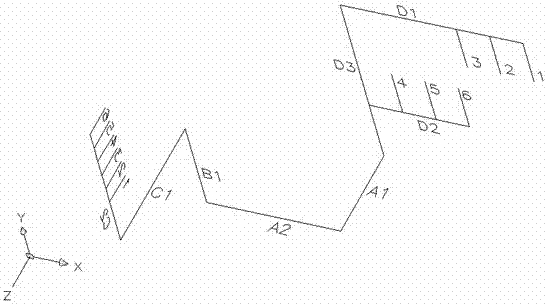

[0024] like Figure 2-7 The shown method for generating nailboard diagrams for the manufacture of electrical wiring harnesses is particularly characterized by the following steps: First, use 3D wiring software to complete the three-dimensional diagram of the wiring harness in three-dimensional space to provide effective data and reference for subsequent processing. Afterwards, the bending parts in the three-dimensional view of the wire harness are folded and converted one by one, so that the three-dimensional wire harness stereogram is transformed into a planar view of the wire harness in the plane space. This step can be processed by manually operating the 3D software, and of course, it can also be processed by software fonts by setting characteristic rules. Improve operation processing effect. Finally, the wiring harness plan is converted into a nailboard drawing for harness manufacturing.

[0025] In terms of a preferred embodiment of the present invention, in order to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com