An integrated high frequency high voltage power supply

A high-frequency high-voltage power supply and integrated technology, which is applied in the direction of measuring electricity, measuring electrical variables, and components of electrical measuring instruments, can solve problems such as cumbersome wiring, heavy equipment, frequent machinery, etc., to reduce the wiring error rate, reduce Types of wiring, the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

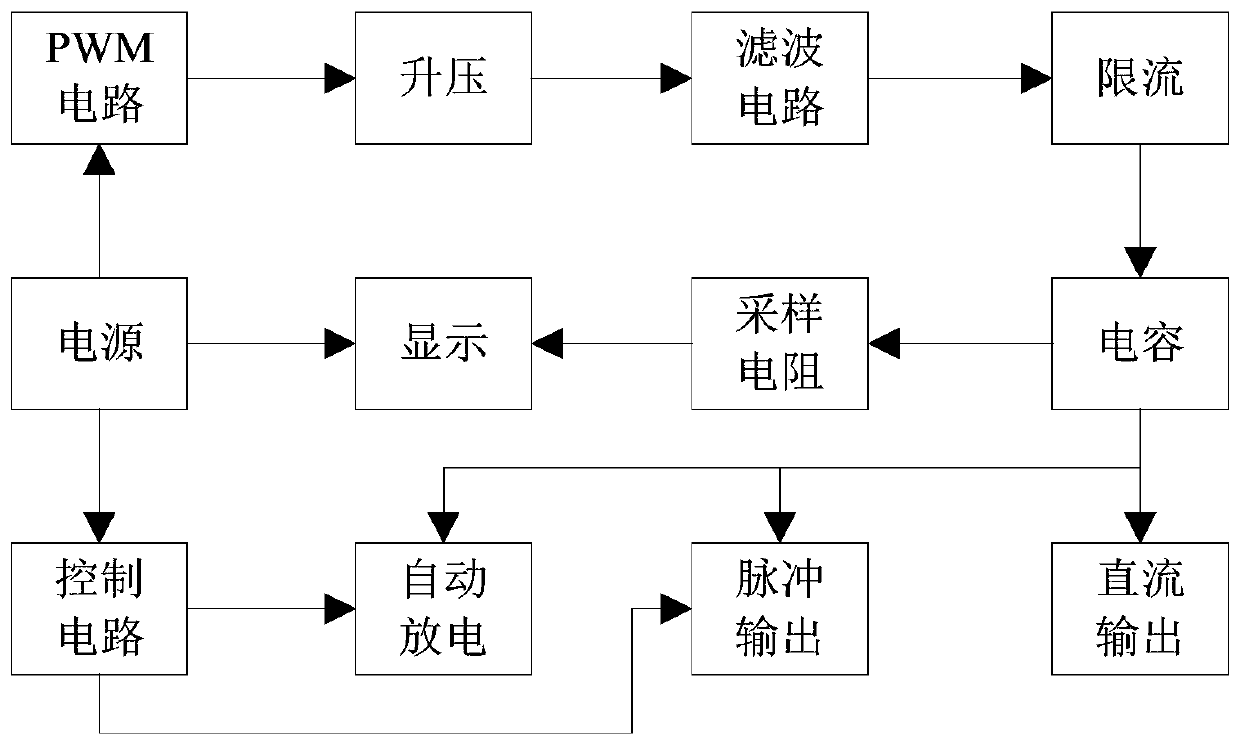

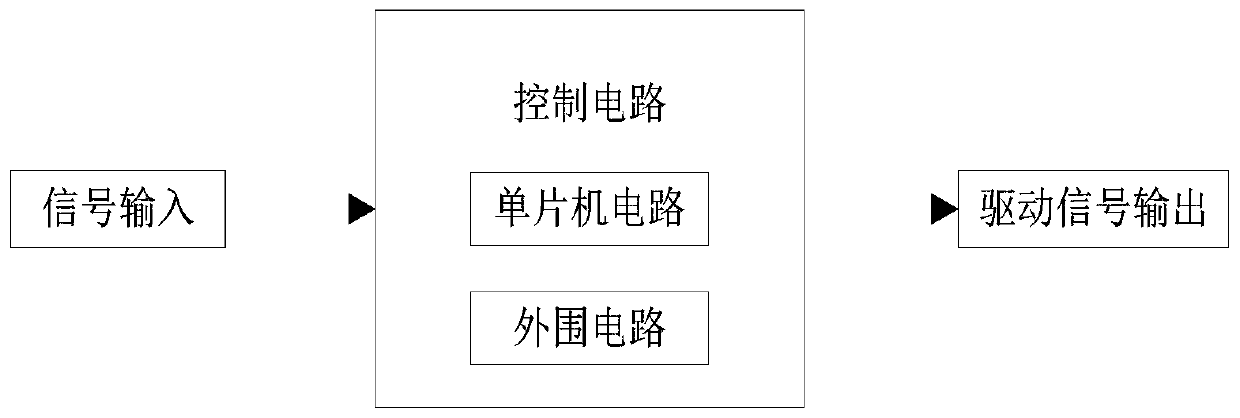

[0036] see figure 1 , the integrated high-frequency high-voltage power supply of the present invention is mainly composed of a PWM (Pulse Width Modulation) circuit, a control circuit, a high-frequency transformer boost circuit, a filter circuit, a current limiting resistor, a high-voltage capacitor, a pulse output control device, a DC high-voltage discharge device, sampling resistor, display device and power supply circuit.

[0037] The PWM circuit is the main channel, through the high-frequency transformer and booster device to store energy for the high-voltage capacitor, the control circuit obtains real-time high voltage through the high-voltage sampling resistor, and forms the control of the pulse output control device and the DC high-voltage discharge device. Inside the structural support, it is equipped with an operation panel and a power supply case;

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com