Pseudo gate removing method

A dummy gate and dry cleaning technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as damage and poor insulation, and achieve improved performance, good shape, and repair of titanium nitride capping layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

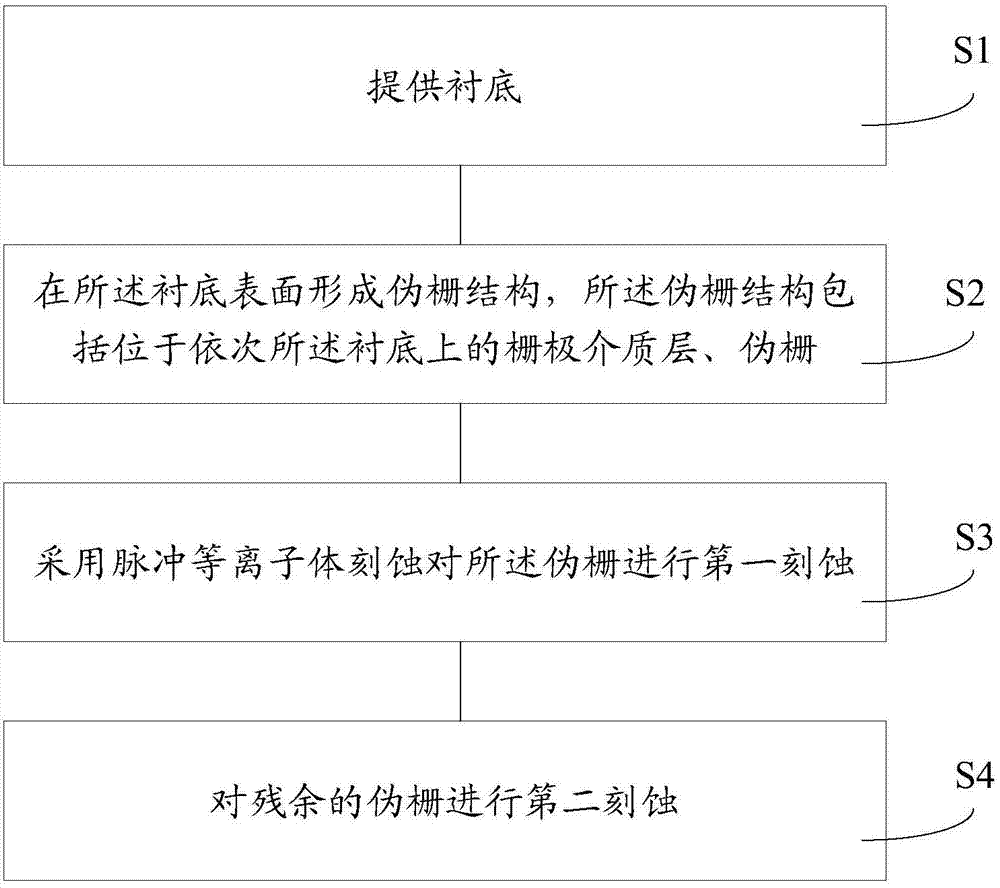

Method used

Image

Examples

Embodiment Construction

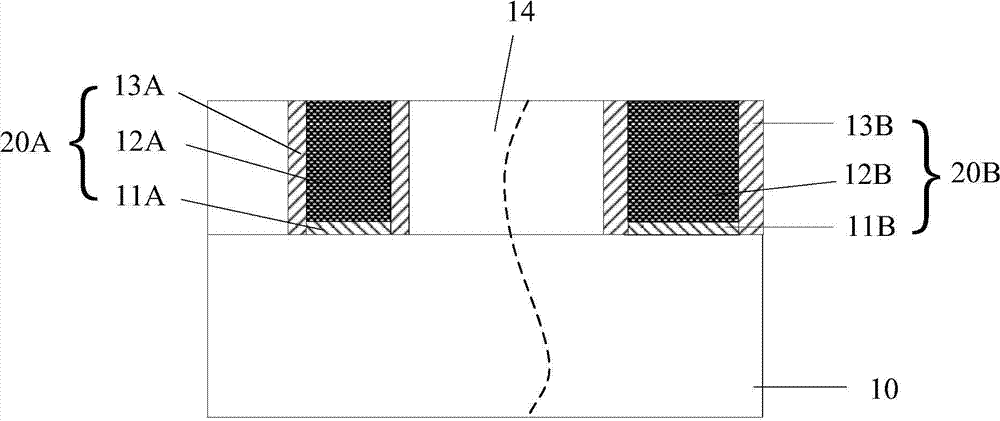

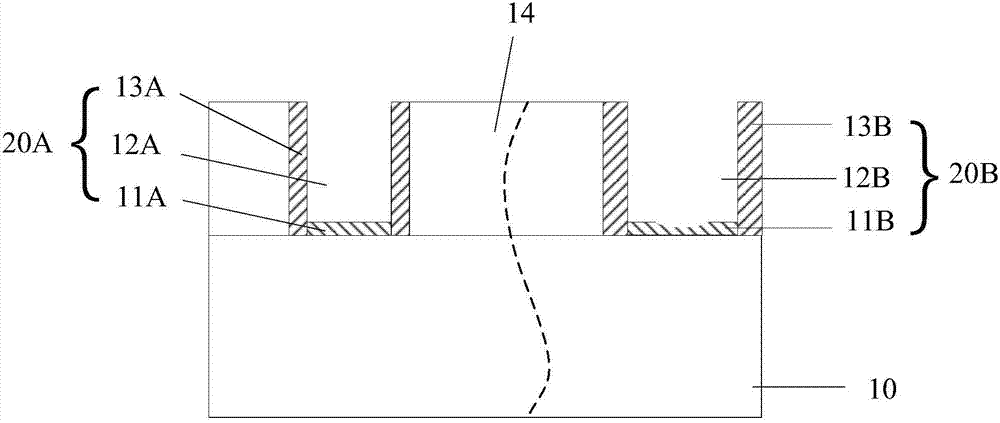

[0029] In the existing methods for removing dummy gates, dry etching is usually used to remove dummy gates, but the removal rates of dummy gates of different sizes are different when dry etching is used to remove dummy gates. The removal rate of dummy gate is faster, but the removal rate of dummy gate with smaller size is slower. When the smaller dummy gate is removed, the gate dielectric layer under the larger dummy gate is easily damaged due to premature exposure. After the dummy gate is removed and the metal gate is filled in the opening, the metal gate The insulation between the transistor and the substrate is poor. When the transistor is an NMOS, damage to the gate dielectric layer will seriously affect the time-dependent breakdown characteristics (Time Dependent Dielectric Breakdown, TDDB) of the NMOS.

[0030] Analyzing the process of removing the dummy gate, for a dummy gate with a larger size, the opening formed on the surface of the dummy gate at the beginning of etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com