Brushless motor and control method thereof

A brushless motor, feedback control technology, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of reducing the efficiency of the whole machine, large commutation influence, etc., to prolong the life of the motor and eliminate errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

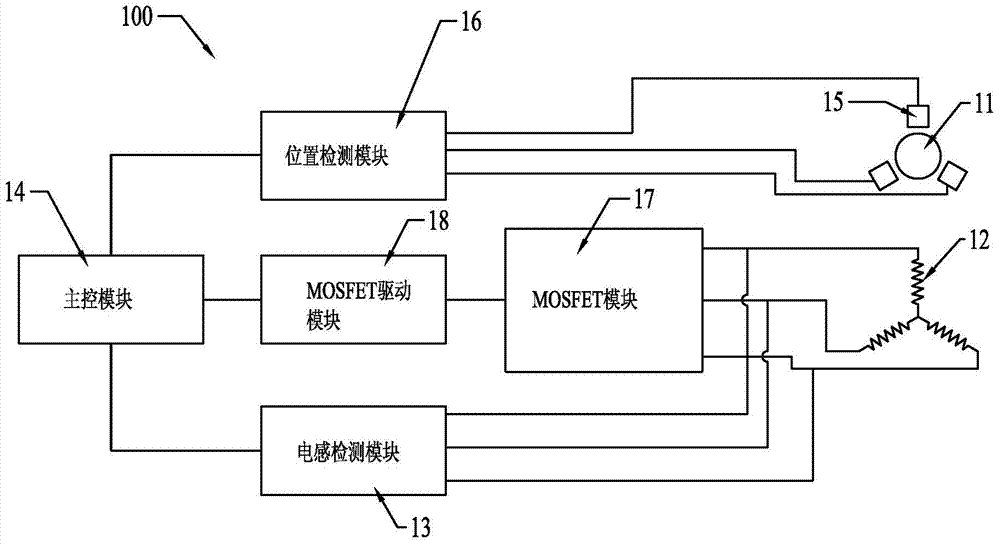

[0022] refer to figure 1 As shown, the brushless motor 100 of the present invention includes: a rotor 11, three sets of stator windings 12, a position detection module (not marked in the figure, the same below), a MOSFET component (not marked in the figure, the same below), an inductance detection module 13 and a control Their main control module 14 .

[0023] Wherein, the position detection assembly includes: 3 detection elements 15 capable of detecting the position of the rotor, and a position detection module 16 capable of receiving feedback signals from the detection elements. The position detection module 16 is electrically connected to the main control module 14 and feeds back the position of the rotor 11 to it. location information.

[0024] The inductance detection modules 13 are respectively electrically connected to the stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com