Anti-static anti-flaming oil-proof water-repellent nylon/cotton blended fabric and preparation method thereof

A blended fabric and anti-static technology, which is applied in textiles, fabrics, textiles, and papermaking, can solve the problems of single anti-static, flame-retardant, oil-proof, and water-repellent functions, and achieve huge social and economic benefits, reduce static electricity, and improve craftsmanship. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

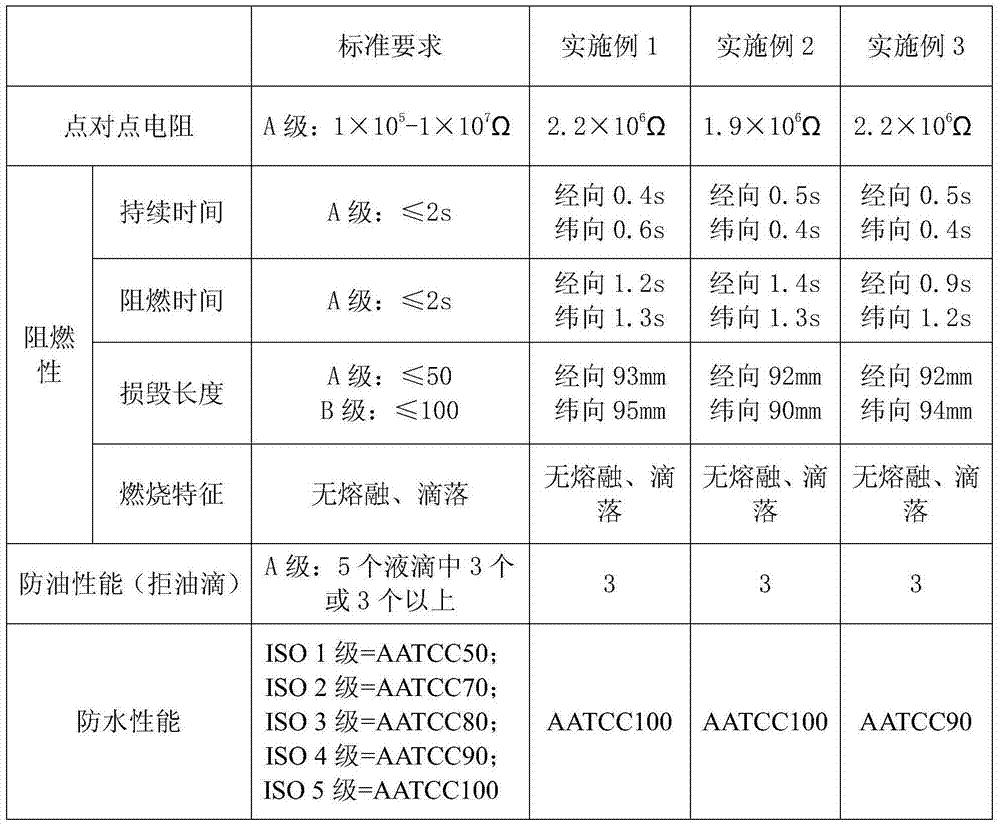

Embodiment 1

[0032] An antistatic, flame-resistant, oil- and water-repellent nylon-cotton blended fabric is prepared by the following method:

[0033] Step 1, anti-static gray fabric weaving

[0034] Nylon 20D / 3F conductive yarn and nylon-cotton blended yarn of 20S N50 / C50 are parallel twisted into conductive yarn, and the twist of conductive yarn is 25 twists / 10cm. Weaving gray fabric with nylon-cotton blended yarn as warp and weft. During the weaving process, conductive yarns were woven into the warp and weft directions at intervals, the distance between two adjacent conductive yarns in the warp direction was 0.5 cm, and the distance between two adjacent conductive yarns in the weft direction was 0.5 cm. Prepare antistatic gray cloth.

[0035] Step two, dye

[0036] The antistatic gray cloth in step 1 is subjected to pre-dyeing treatment, dipped and rolled on a dyeing machine, then dried and soaped to obtain an antistatic nylon-cotton blended colored cloth.

[0037] Step 3, Flame Ret...

Embodiment 2

[0043] An antistatic, flame-resistant, oil- and water-repellent nylon-cotton blended fabric is prepared by the following method:

[0044] Step 1, anti-static gray fabric weaving

[0045] Nylon 20D / 3F conductive yarn and nylon-cotton blended yarn of 20S N50 / C50 are parallel twisted into conductive yarn, and the twist of conductive yarn is 40 twists / 10cm. Weaving gray fabric with nylon-cotton blended yarn as warp and weft. During the weaving process, conductive yarns were woven into the warp and weft directions at intervals, the distance between two adjacent conductive yarns in the warp direction was 1 cm, and the distance between two adjacent conductive yarns in the weft direction was 1 cm. Prepare antistatic gray cloth.

[0046] Step two, dye

[0047] The antistatic gray cloth in step 1 is subjected to pre-dyeing treatment, dipped and rolled on a dyeing machine, then dried and soaped to obtain an antistatic nylon-cotton blended colored cloth.

[0048] Step 3, Flame Retarda...

Embodiment 3

[0054] An antistatic, flame-resistant, oil- and water-repellent nylon-cotton blended fabric is prepared by the following method:

[0055] Step 1, anti-static gray fabric weaving

[0056] Nylon 20D / 3F conductive yarn and nylon-cotton blended yarn of 20S N50 / C50 are parallel twisted into conductive yarn, and the twist of conductive yarn is 50 twists / 10cm. Weaving gray fabric with nylon-cotton blended yarn as warp and weft. During the weaving process, conductive yarns were woven into the warp and weft directions at intervals, the distance between two adjacent conductive yarns in the warp direction was 2 cm, and the distance between two adjacent conductive yarns in the weft direction was 2 cm. Prepare antistatic gray cloth.

[0057] Step two, dye

[0058] The antistatic gray cloth in step 1 is subjected to pre-dyeing treatment, dipped and rolled on a dyeing machine, then dried and soaped to obtain an antistatic nylon-cotton blended colored cloth.

[0059] Step 3, Flame Retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com