Filter device

A filter device and filter net technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as exhaust gas cannot be treated, smoke and exhaust gas pollutants, staff injury, etc., and achieve low cost and good results , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

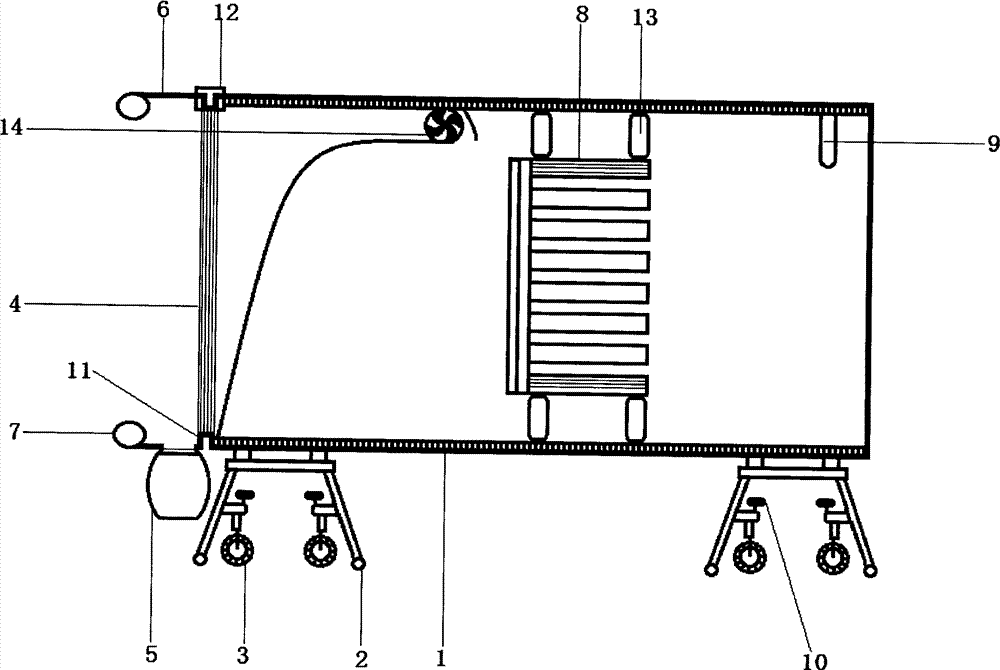

[0014] As shown in Figure 1, a filter device includes a filter box 1, which is characterized in that: the lower side of the filter box 1 is provided with a support leg 2, and the support leg 2 is connected to the filter box 1 through a rotating shaft to support The inner side of the leg 2 is connected with a moving pulley 3 by welding, the left side of the filter box 1 is provided with a dust filter 4, the lower side of the smoke filter 4 is provided with a dust collection box 5, and the left side of the smoke filter 4 is provided with a gas filter. The upper and lower sides of the inlet 6 and the gas inlet 6 are provided with fixing buckles 7, and the middle of the filter box 1 is provided with a waste gas treatment device 8, and the right side of the waste gas treatment device 8 is provided with a detector 9.

[0015] As a preferred mode of the present invention, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com