PET three-layer scratch resistant protective film

A protective sticker and anti-scratch technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of unspecified hardness and transmittance, low light transmittance, low hardness, etc., and achieve The anti-scratch effect is obvious, the screen is protected, and the performance is durable and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

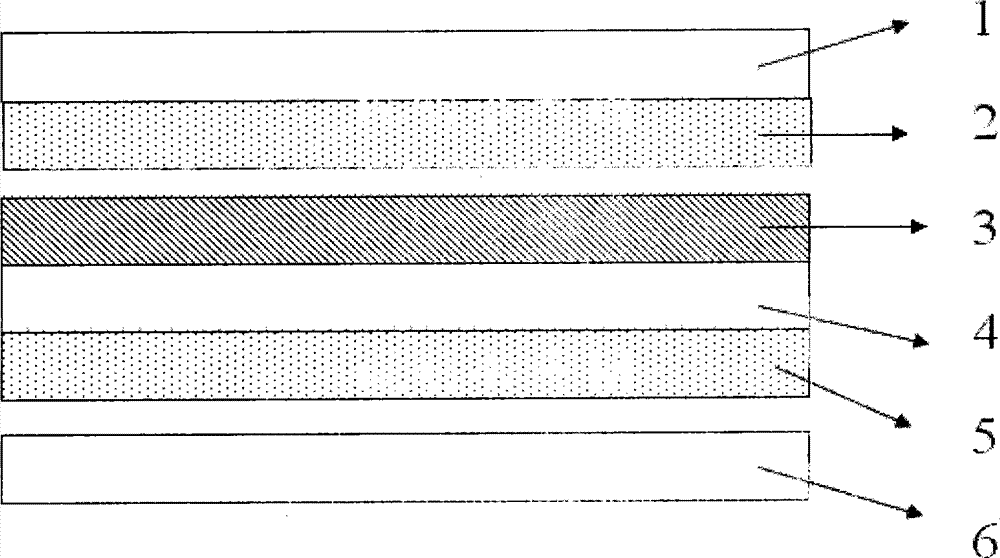

[0034] A kind of PET three-layer anti-scratch protective film, the protective layer is the PET original film 1 and the average particle diameter size of acidic nano silicon dioxide hydrosol < The thickness of the 100nm silica gel layer 2 is 15 μm, (viscosity is 1-2g); the hardness of the use layer is 5H, and the coating thickness is 5 micron hardened coating 3, (the model of Yihua Toray is UY42 or the model of SKC is H86H Thickness is 125 μm) PET original film 4 and (viscosity is 5-8g) the average particle diameter size of the silica gel layer 5 thickness of <100nm of the acidic nano silicon dioxide hydrosol is 25 μm; It is the original PET film 6 whose thickness is 50 μm for G01.

[0035] The thickness of the original PET film 4 used in the above embodiments may be 125 μm.

[0036] The thickness of the protective layer PET original film 1 in the above embodiment may be 50 μm.

[0037] In the above embodiment, the thickness of the original PET film 6 of the release layer may...

Embodiment 2

[0040] A kind of PET three-layer anti-scratch protective film, the protective layer is the PET original film 1 and the average particle diameter size of acidic nano silicon dioxide hydrosol < The thickness of the 100nm silica gel layer 2 is 15 μm, (viscosity is 1-2g); the hardness of the use layer is 5H, and the coating thickness is 5 micron hardened coating 3, (the model of Yihua Toray is UY42 or the model of SKC is H86H The thickness is 188 μ m) PET original film 4 and (viscosity is 5-8g) the average particle diameter of the silica gel layer 5 thickness of the acidic nano silicon dioxide hydrosol <100nm thickness is 25 μ m; It is the original PET film 6 whose thickness is 75 μm for G01.

[0041] The thickness of the original PET film 4 used in the above embodiment may be 188 μm.

[0042] The thickness of the protective layer PET original film 1 in the above embodiment may be 100 μm.

[0043] In the above embodiment, the thickness of the original PET film 6 of the release l...

Embodiment 3

[0046] A kind of PET three-layer anti-scratch protective film, the protective layer is the PET original film 1 and the average particle diameter size of acidic nano silicon dioxide hydrosol < The thickness of the 100nm silica gel layer 2 is 13 μm, (viscosity is 1-2g); the hardness of the use layer is 5H, and the coating thickness is 4 micron hardened coating 3, (the model of Yihua Toray is UY42 or the model of SKC is H86H Thickness is 125 μm) PET original film 4 and (viscosity is 5-8g) the average particle diameter size of the silica gel layer 5 thickness of <100nm of the acidic nano silicon dioxide hydrosol is 25 μm; It is the original PET film 6 whose thickness is 38 μm for G01.

[0047] The thickness of the original PET film 4 used in the above embodiments may be 100 μm.

[0048]The thickness of the protective layer PET original film 1 in the above embodiment may be 38 μm.

[0049] In the above embodiment, the thickness of the original PET film 6 of the release layer may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com