Hyperbranched Modification Method of Cellulose Nanofibers

A nanofiber and cellulose technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of low content of active functional groups, limited adsorption capacity, no breakthrough in adsorption performance, etc., and achieve high porosity, strong The effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention are described in conjunction with the embodiments.

[0024] The hyperbranched modification method of cellulose nanofiber comprises the following steps:

[0025] (1) Preparation of cellulose nanofibers CNFs

[0026] First, disperse the bamboo pulp cellulose into water with an emulsifier to obtain a 1% dispersion; then process it with an ultrasonic cell pulverizer; finally process it with a high-speed shear homogenizer to obtain cellulose nanofibers;

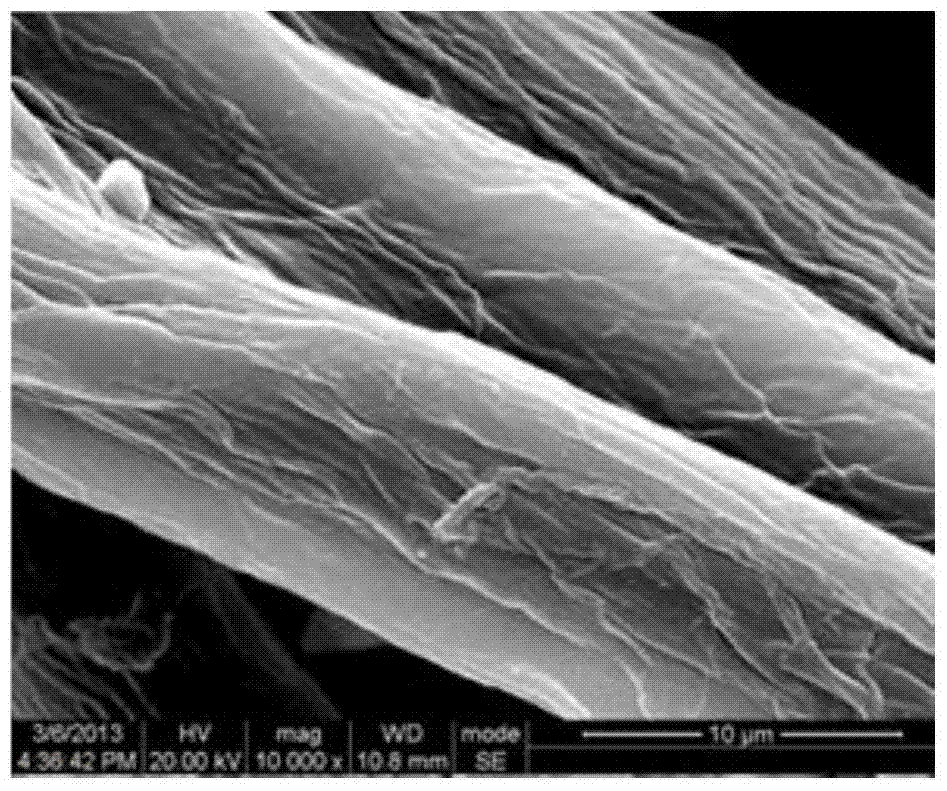

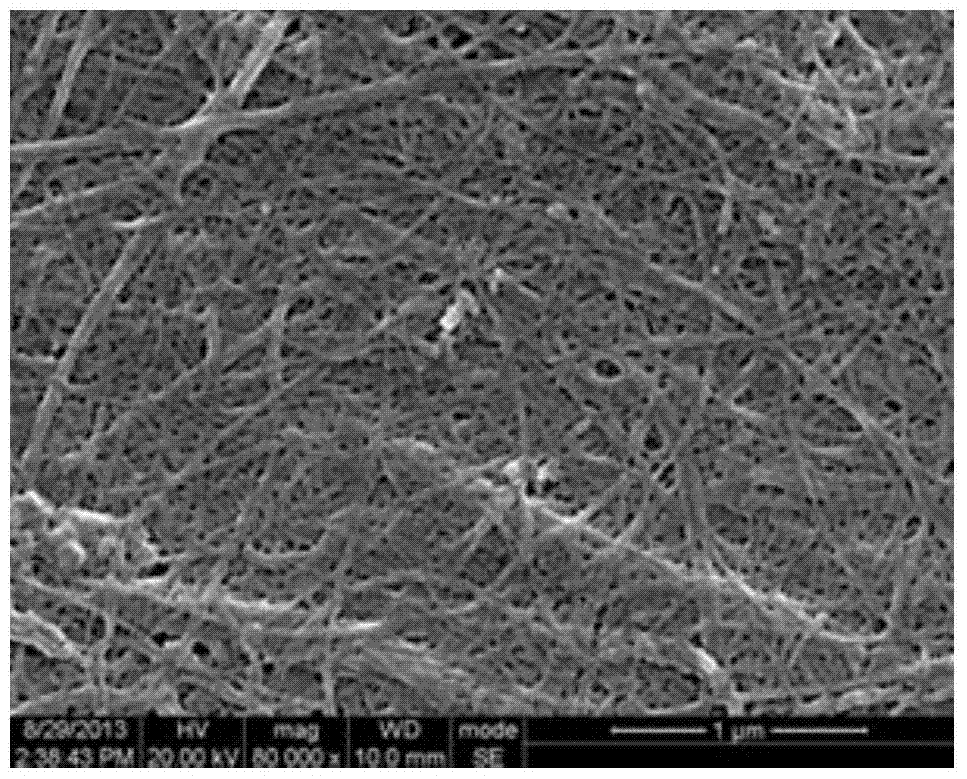

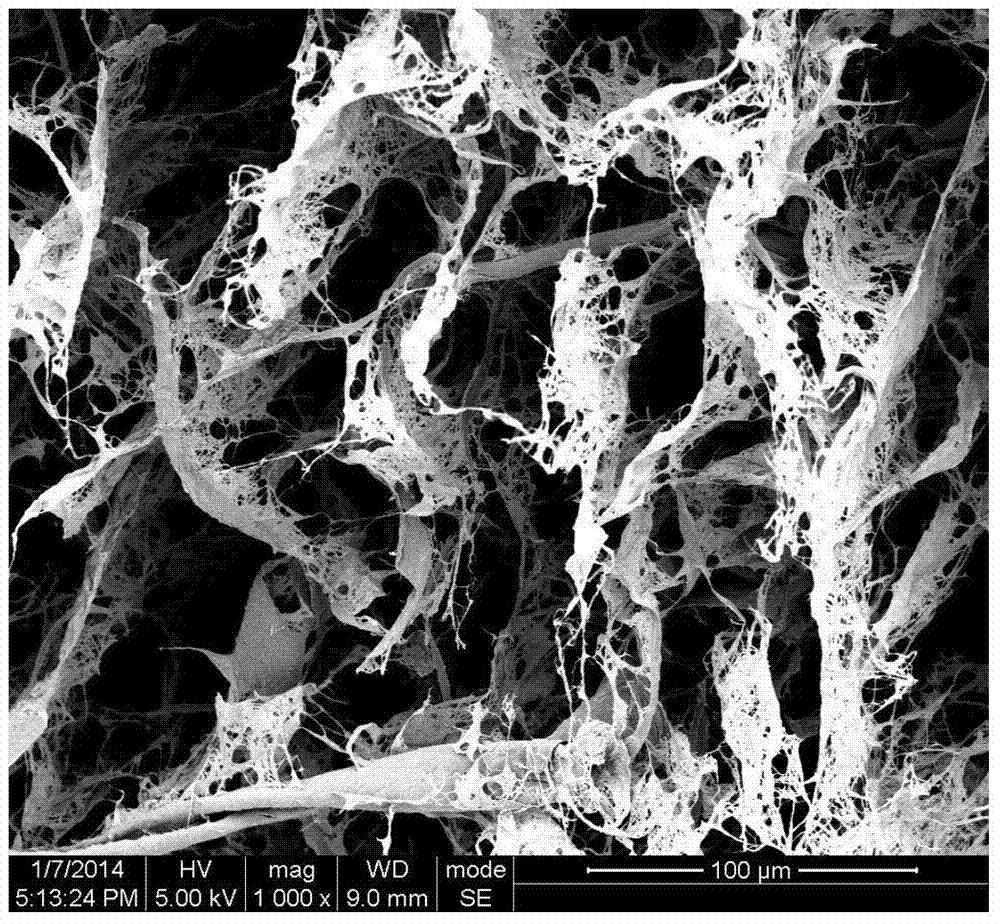

[0027] Such as figure 1 As shown in the scanning electron microscope photo of untreated bamboo pulp cellulose, it can be seen that the diameter of the bamboo pulp fiber is about 10 μm, and the surface is relatively rough. Such as figure 2 As shown, however, almost all bamboo fibers after ultrasonic crushing and high-speed shear homogenization have become nanofibers, and the diameters of the prepared CNFs are mainly distributed between 20-50nm, indicating that the ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com