Prestressed concrete-steel tank beam bond beam continuous beam bridge

A technology of concrete girder and concrete box girder, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as the vulnerability of bridge deck pavement, and achieve the effect of reducing the building height of the main bridge, increasing the spanning capacity, and reducing the project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

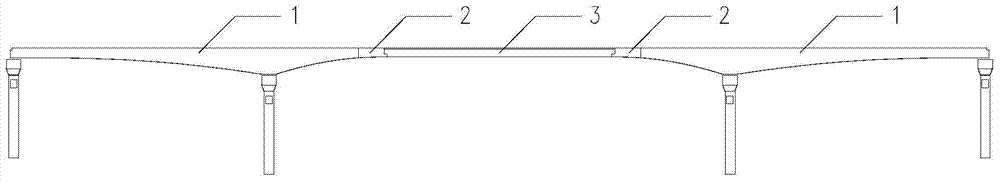

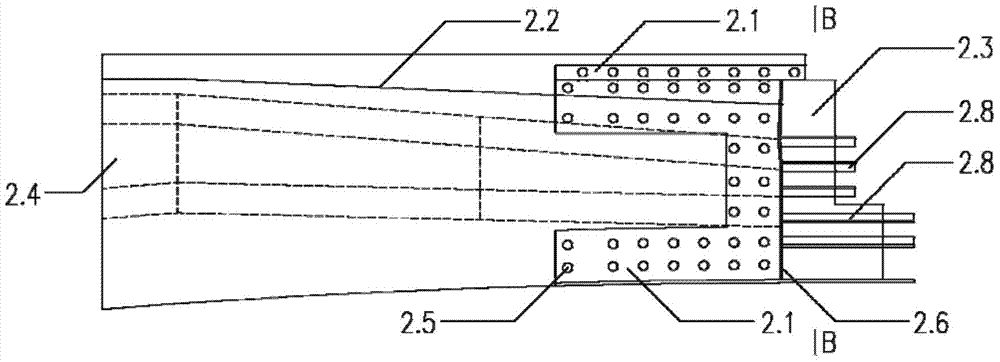

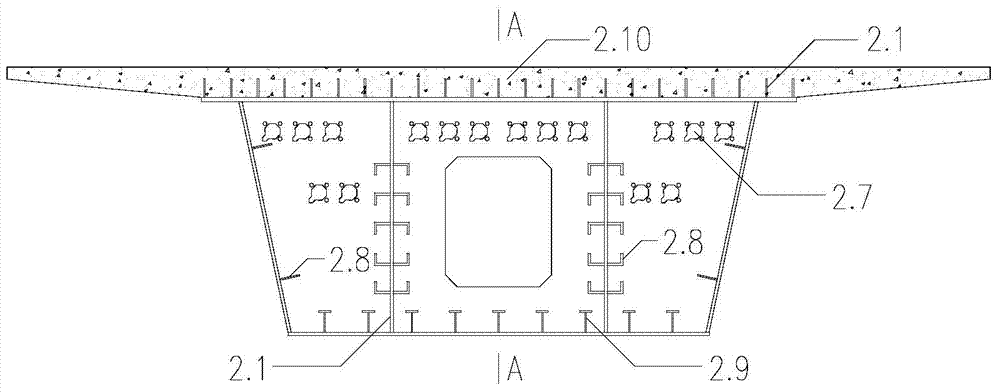

[0027] The invention includes a bridge pier and a beam structure, and the beam structure is provided with a prestressed concrete box girder section 1 , a concrete-steel channel beam combination beam section 3 and a steel-concrete transition section 2 . Concrete-steel channel beam combined beam section 3 is located in the positive bending moment area of the span, and is connected to prestressed concrete box girder section 1 through steel joint 2.3 of steel-concrete transition section 2 at both ends. In order to realize the smooth transmission of force between different beam segments, the steel joint 2.3 is set in the positive and negative bending moment alternating area.

[0028] The concrete-steel channel beam combined beam section 3 is formed by connecting the lower steel channel beam 3.1 and the upper concrete bridge deck 3.5 through shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com