Filling body for goaf in deep metal mine, filling method and system thereof

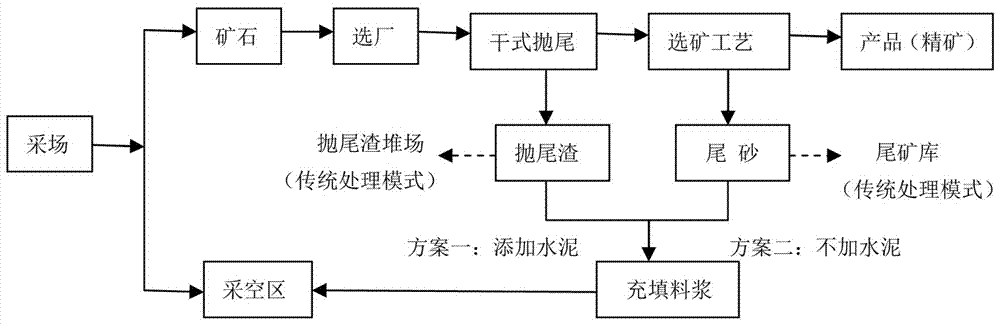

A technology for backfill and goaf, which is applied in the fields of backfill, mining equipment, earth-moving drilling, etc., can solve problems such as hidden safety hazards, environmental pollution, consumption, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

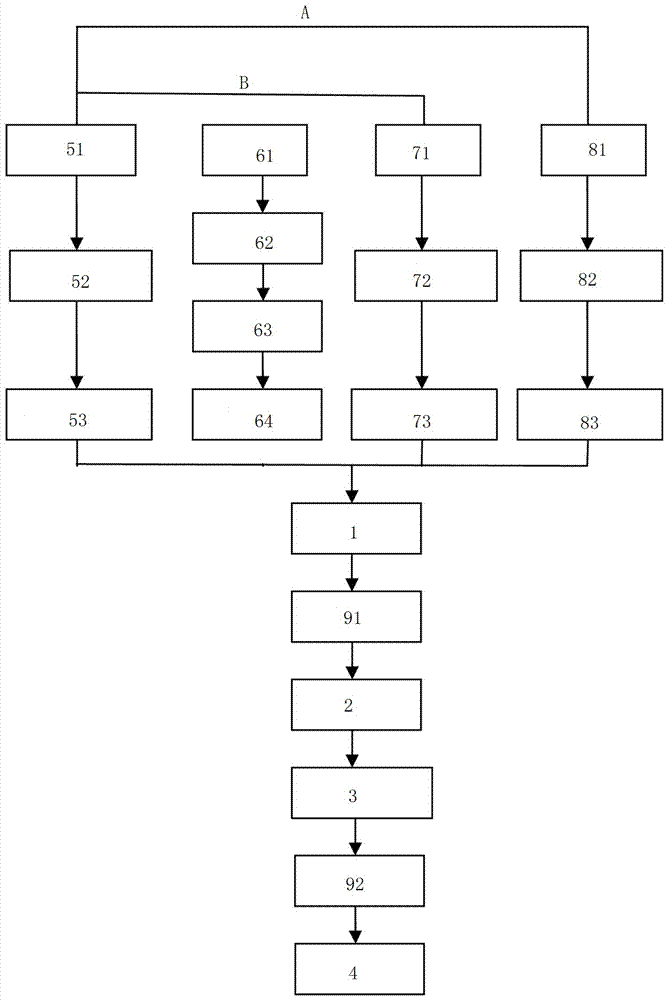

Method used

Image

Examples

Embodiment 1

[0034] The filling body used in the goaf of metal mines provided by the present invention is mixed with tailings, tailings and water in a weight ratio of 2.75:1:1, then stirred evenly, and then filled into the goaf through the filling system. Can.

Embodiment 2

[0036] A filling body used in goafs of metal mines, which is made of tailings, tailings, water, and cement in a weight ratio of 2.75:1:1:0.25, then stirred evenly, and filled into the goaf through the filling system area.

Embodiment 3

[0038] The filling body used in the goaf of metal mines provided by the present invention is mixed with tailings, tailings and water in a weight ratio of 3:0.75:1, then stirred evenly, and then filled into the goaf through the filling system. Can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com