Two-chamber type regenerative catalytic organic waste gas purification device having back blowing function

A technology for organic waste gas and catalytic purification, applied in the field of air pollution control, can solve the problems of increased quantity, complex control, increased investment, etc., and achieve the effects of low cost, improved purification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the invention will be described in further detail below in conjunction with the drawings and specific embodiments. The embodiments cannot be repeated here, but the implementation of the invention is not limited to the following embodiments.

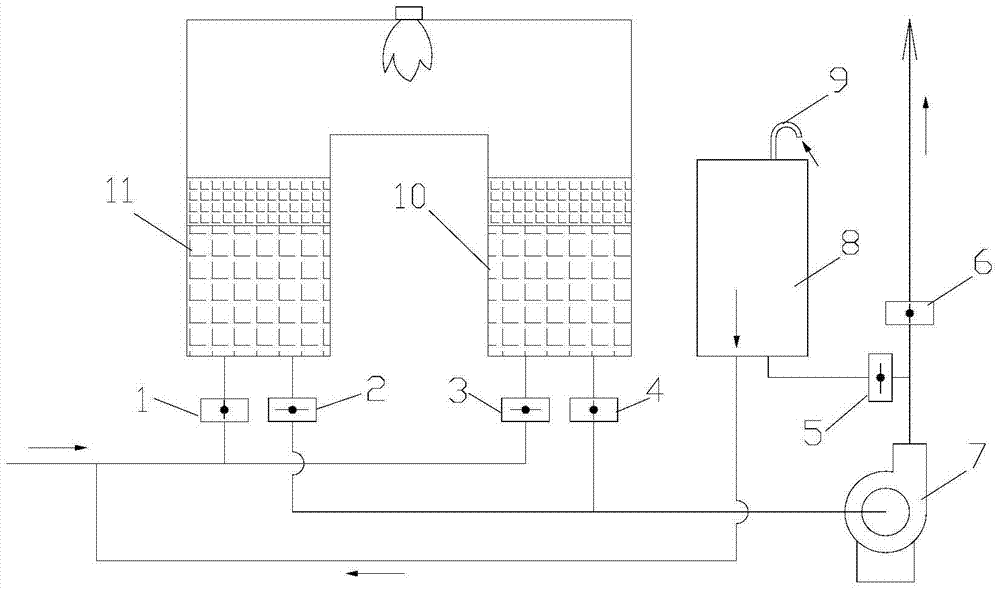

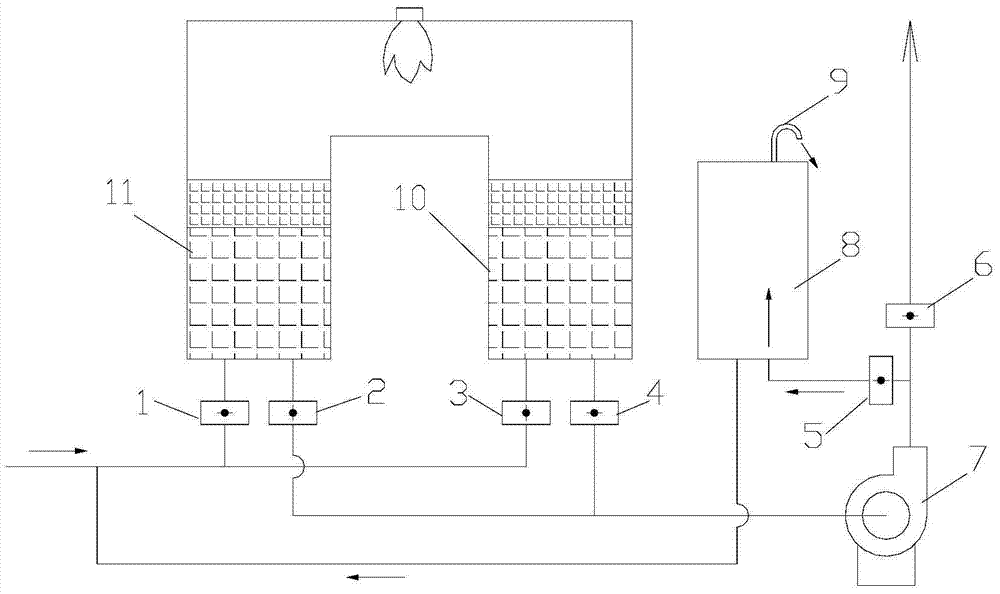

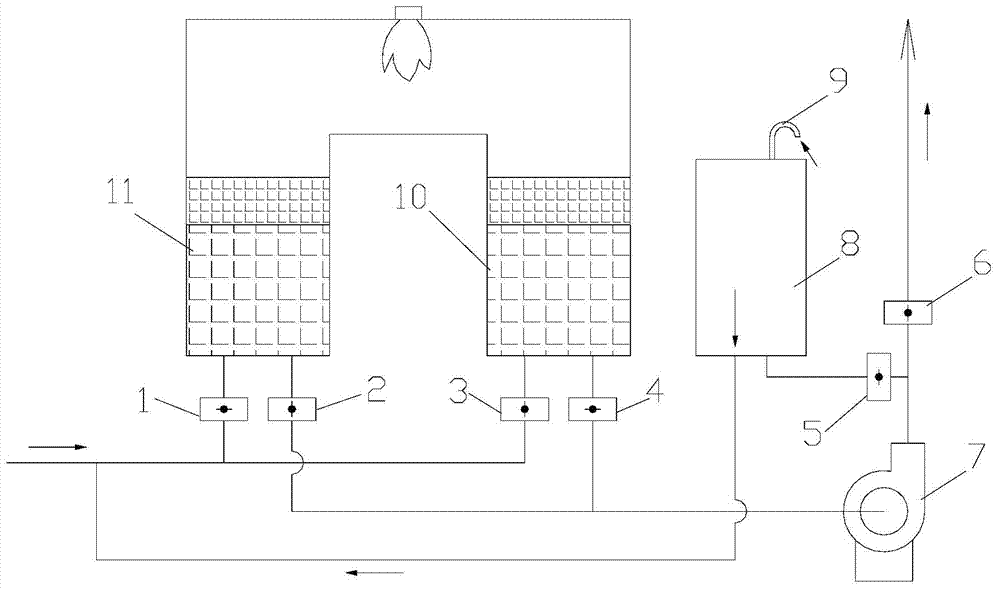

[0022] A two-chamber thermal storage catalytic and purification device with back-blowing function includes a two-chamber thermal storage catalytic combustion device having a first thermal storage catalytic reaction chamber 11 and a second thermal storage catalytic reaction chamber 10. The first heat storage catalytic reaction chamber 11 and the second heat storage catalytic reaction chamber 10 are both filled with a ceramic heat storage body layer and a catalyst layer. The first heat storage catalytic reaction chamber 11 and the second heat storage catalytic reaction chamber The air inlet of 10 is connected to the organic waste gas inlet pipe through the first valve 1 and the third valve 3 respectively, and further inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com