Indoor smoke channel mounting process of sintering engineering

An installation process and internal flue technology, which is applied in the direction of furnace type, waste heat treatment, furnace, etc., can solve the problems of low installation efficiency, high site construction requirements, and low installation cost, and achieve high installation efficiency, low site construction requirements, The effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

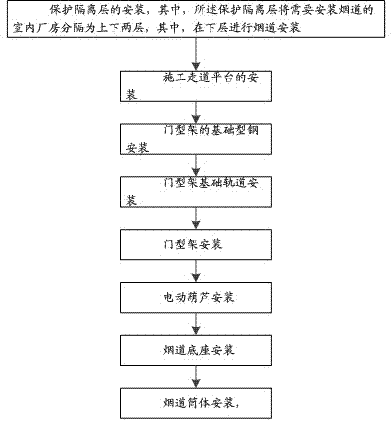

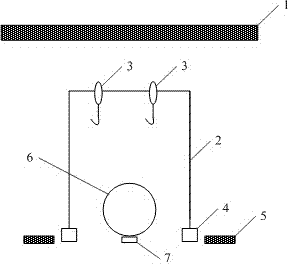

[0034] In the first embodiment, a sintering engineering indoor flue installation process is provided, please refer to Figure 1-Figure 2 , the process includes:

[0035] Step 1: Installation of the protective isolation layer 1, wherein the protective isolation layer 1 separates the indoor factory building where the flue needs to be installed into upper and lower floors, and according to the site structure and construction progress, the bulk material funnel (also known as the small grid funnel) ) layers are separated, and the flue installation is performed on the lower layer;

[0036] Step 2: installation of construction walkway platform 5;

[0037] Step 3: Install the basic section steel of portal frame 2;

[0038] Step 4: Install the portal frame track 4;

[0039] Step 5: Install the portal frame 2;

[0040] Step 6: Electric hoist 3 installation;

[0041] Step 7: Install the flue base 7;

[0042] Step 8: Install the flue cylinder body 6, wherein, steps 2-8 are all insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com