An automatic monitoring device for runoff and sediment

An automatic monitoring and flow monitoring technology, applied in the direction of measuring devices, volume/mass flow generated by mechanical effects, instruments, etc., can solve the problems of labor and time consumption, long drying duration, prolonged working time, etc., to save time , The effect of saving manpower and material resources and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

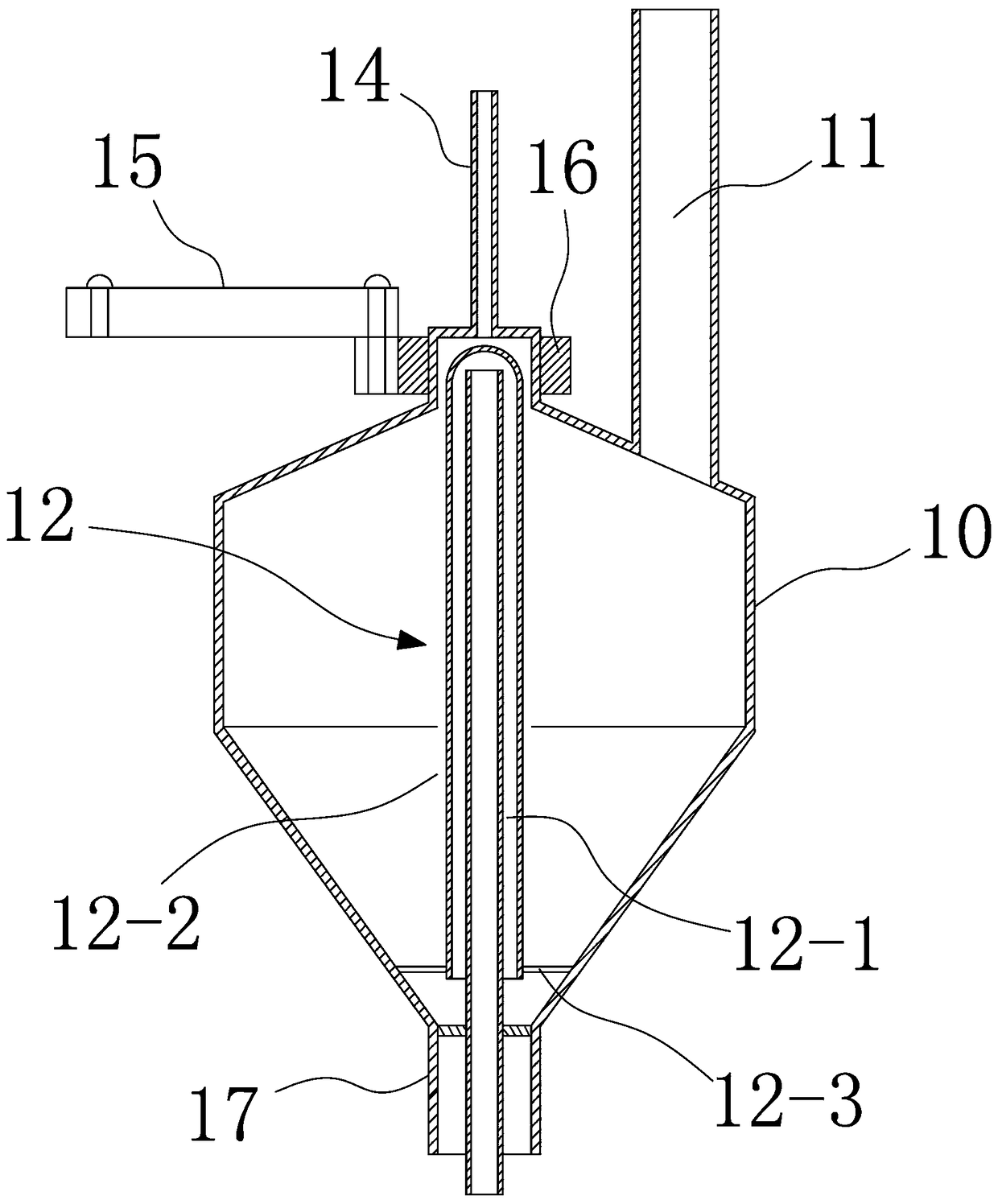

[0057] Attached below Figure 1-9 The present invention is further described in detail with specific embodiments.

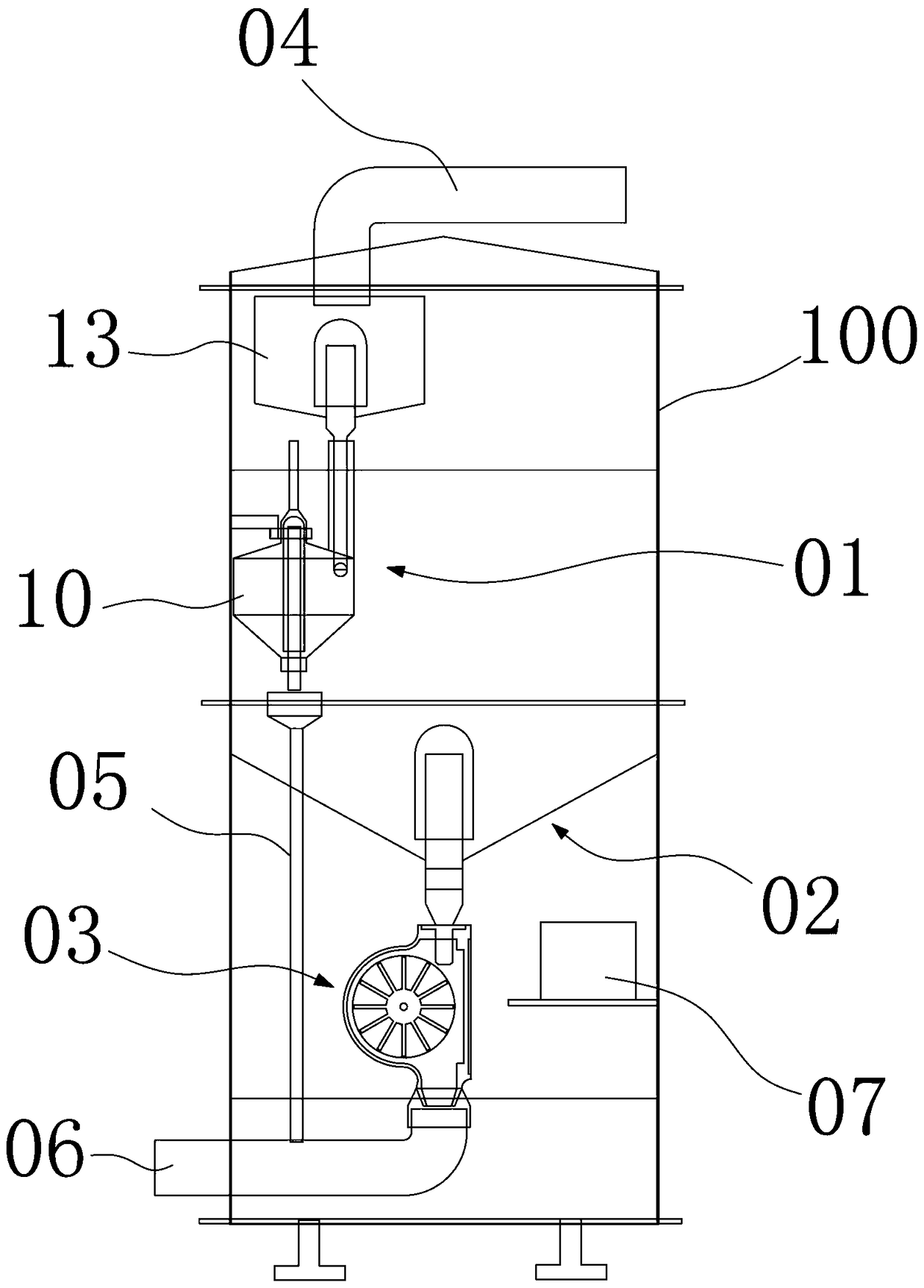

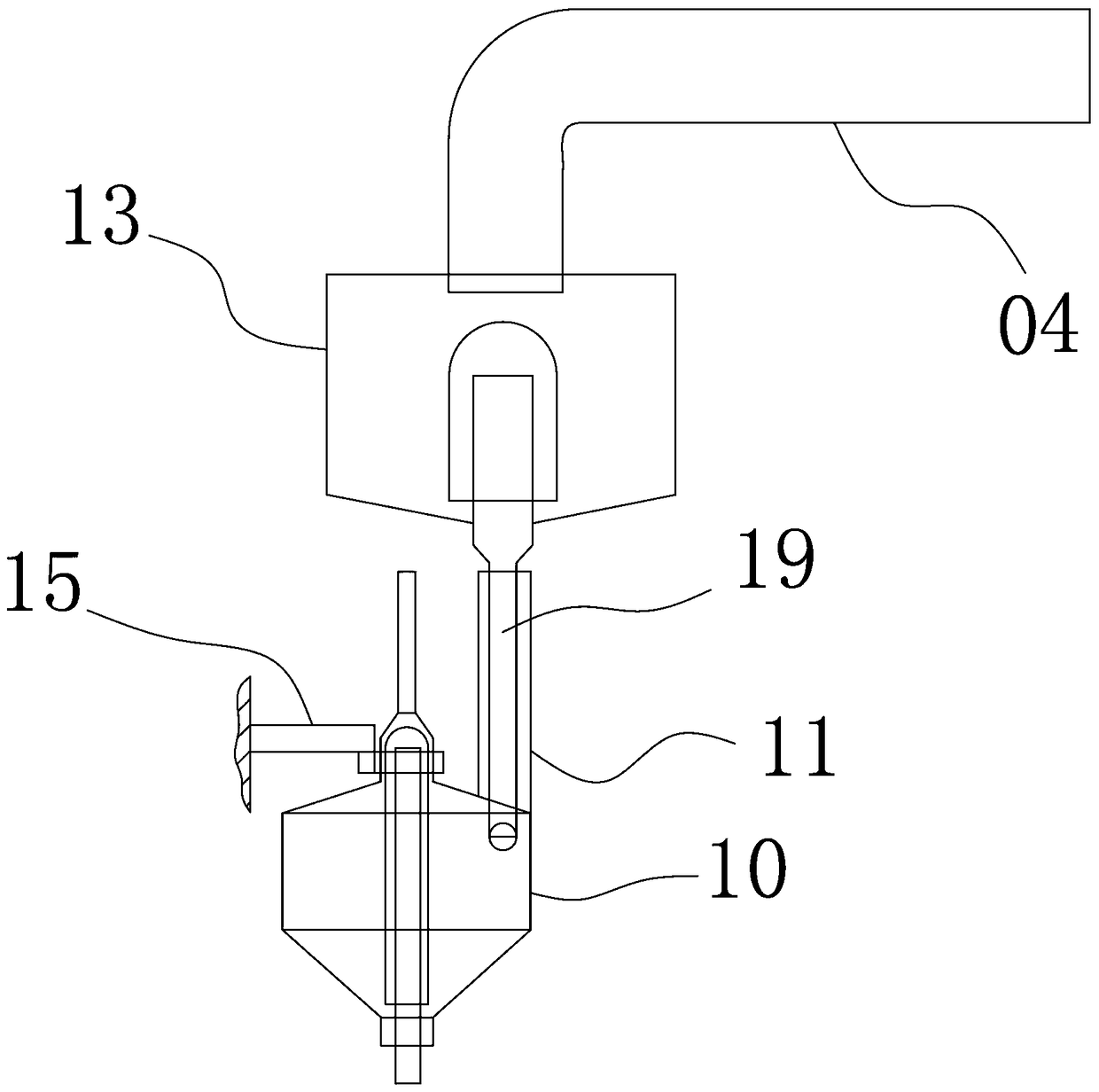

[0058] as attached figure 1 A runoff sediment automatic monitoring device shown, which includes:

[0059] A cylindrical protection cylinder 100, the protection cylinder 100 is provided with a water inlet pipe 04 for receiving the runoff muddy water in the monitoring area, the bottom of the protection cylinder 100 is provided with a drainage pipe 06; the protection cylinder 100 is provided with Sampling and weighing device 01, confluence device 02, flow monitoring device 03 and controller 07 are arranged. The sampling and weighing device 01 receives a part of muddy water in the water inlet pipeline 04 for weighing, and transmits the data to the controller 07, or samples The weighing device 01 receives a part of the muddy water at the outlet of the flow monitoring device 03 for weighing; the converging device 02 collects the muddy water in the water inlet pipe 04...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com