On-site test method of emulsified asphalt spraying amount

A technology of emulsified asphalt and on-site testing, which can solve the problems of edge emulsified asphalt loss and the inability to obtain the accurate value of the spreading area by removing certain components and weighing, so as to avoid quality reduction and accurately spread the amount of emulsified asphalt Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

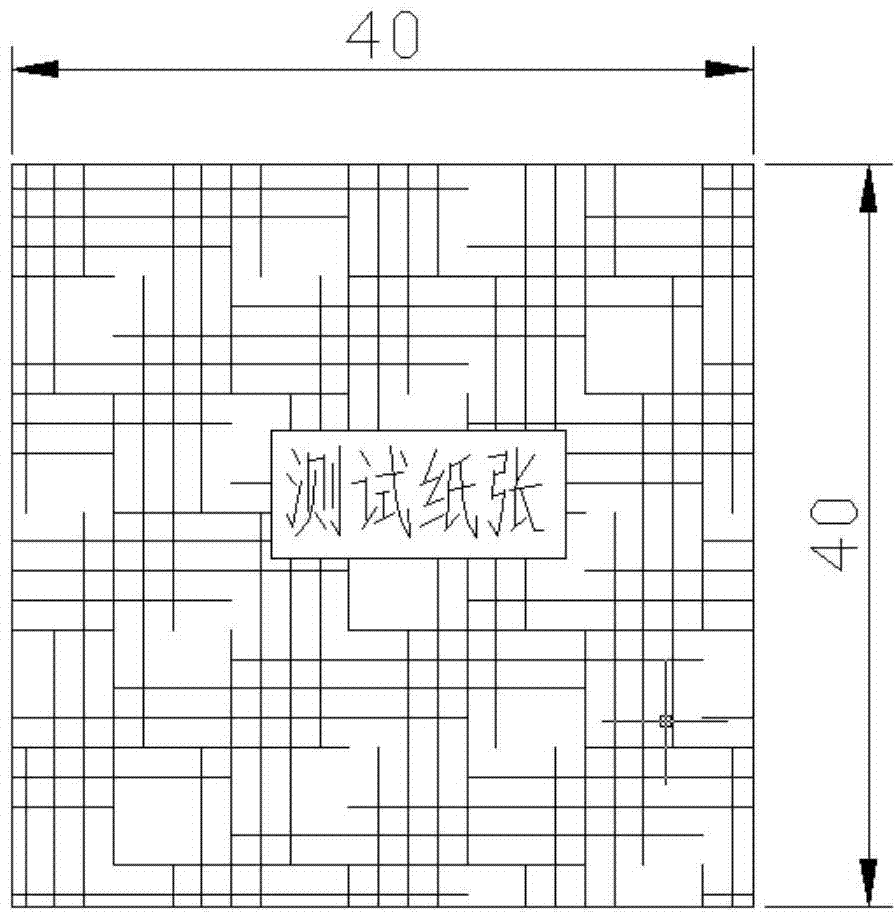

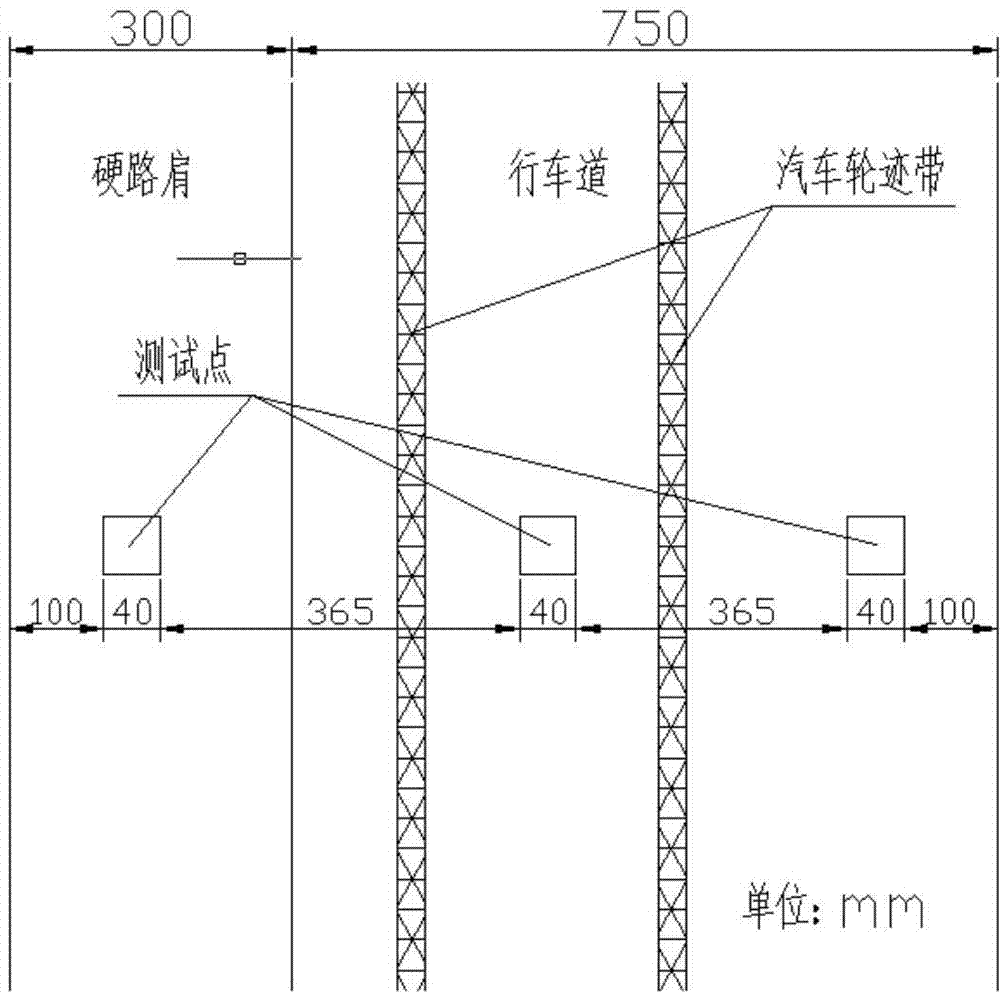

[0025] A method for on-site testing of emulsified asphalt spreading amount, the specific steps of the on-site testing method are as follows: 1) take a kind of paper with a large water absorption rate and not easily damaged, and the quality of the paper is ≧200g / m 2 , water absorption per unit area ≧ 2.5 times the quality of paper, bursting strength should be ≧ 500g / m 2 , see the specific size figure 1 ; 2) Weigh the mass m of each paper before the test 0 , The area F of the paper, place the paper on the road surface to be tested, the test frequency is one place every 200 meters, and three points are tested at each place (that is, three pieces of paper need to be placed at the same time), the layout of the test points is shown in figure 2 ; 3) Lift the four corners of the paper slightly to prevent asphalt loss after the distributor truck passes by, and measure the mass m of the paper and emulsified asphalt within 3 minutes 1 , remove the corresponding paper mass m 0 The qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com