Cylindrical case and method for manufacturing cylindrical case

A cylindrical, shell technology, applied in chemical instruments and methods, machines/engines, high-efficiency propulsion technology, etc., can solve problems such as gap generation, and achieve the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described based on the drawings.

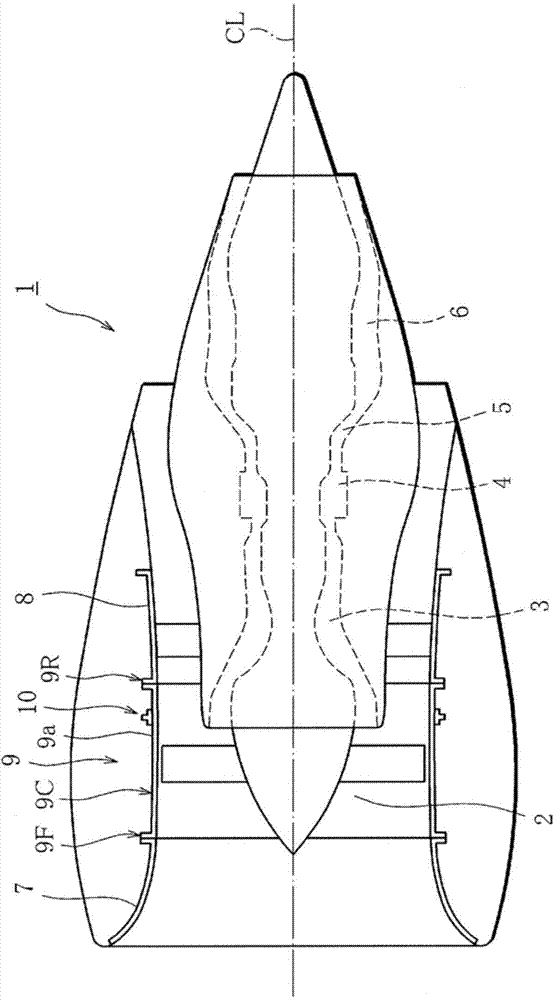

[0033] Figure 1 ~ Figure 4C One embodiment of the cylindrical casing of the present invention is shown, and in this embodiment, a case where the cylindrical casing of the present invention is a fan casing of a jet engine for an aircraft will be described as an example.

[0034] like figure 1 As shown, a jet engine 1 for an aircraft sends air taken in from the front (left in the figure) through a fan 2 having a plurality of fan blades to a compressor 3, injects fuel into the air compressed by the compressor 3 and burns Combustion is carried out in the chamber 4, and the high-pressure turbine 5 and the low-pressure turbine 6 are rotated by the expansion of the resulting high-temperature gas.

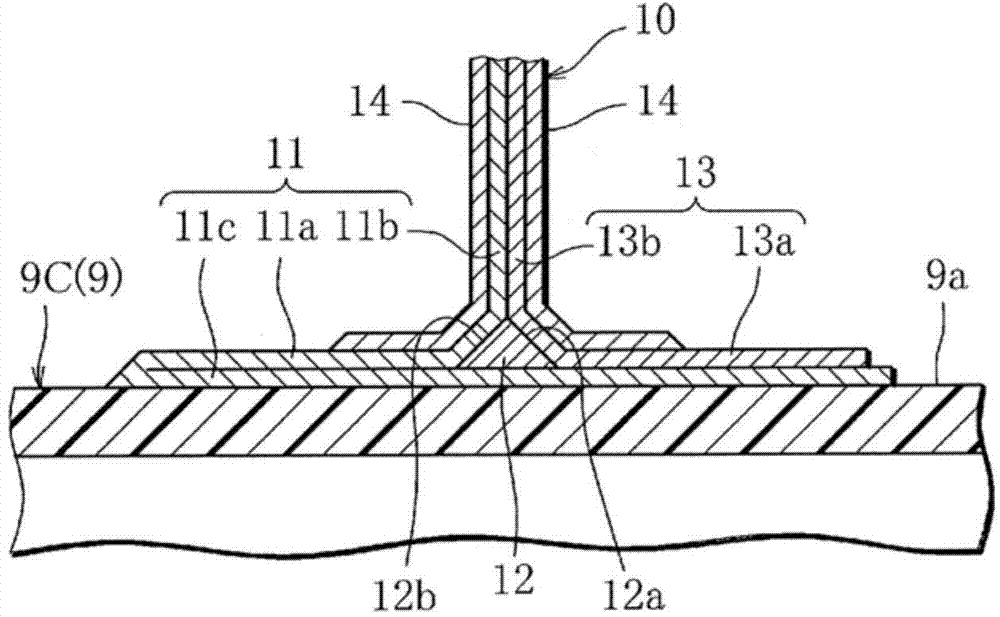

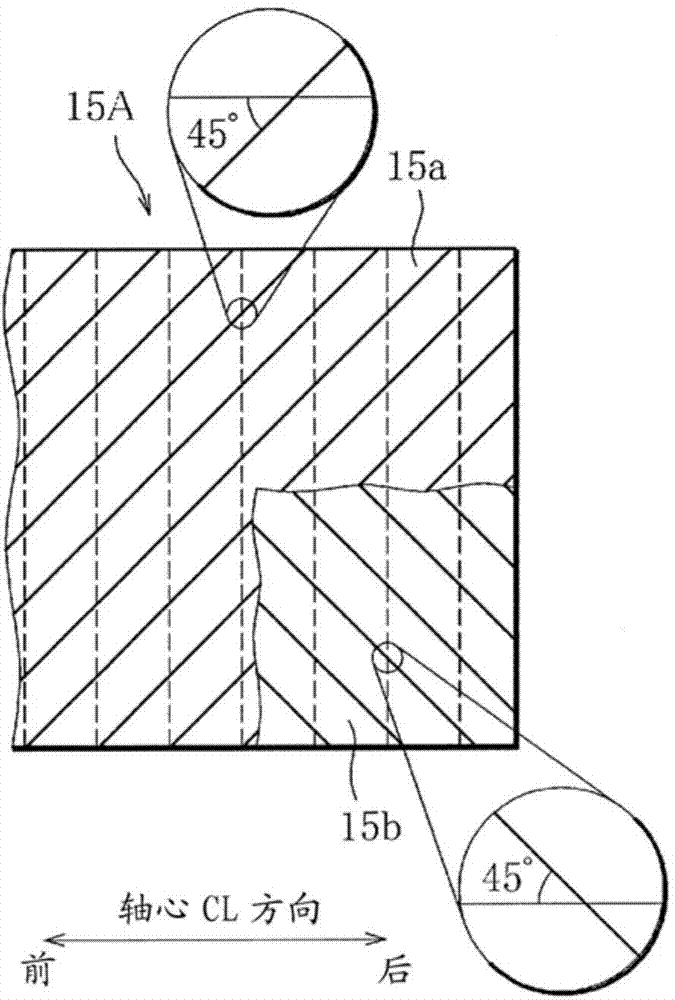

[0035] The fan case 9 covering the plurality of fan blades of the fan 2 has a cylindrical case main body 9C, and an outward flange 10 annularly arranged in the circumferential direction on the outer per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com