A compact three-phase separation method and device

A three-phase separation and separation method technology, applied in the field of compact three-phase separation and devices, can solve the problems of insufficient suction volume, insufficient swirl field strength, affecting oil removal effect, etc., and achieve high performance, reasonable generation and distribution. , The device has the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

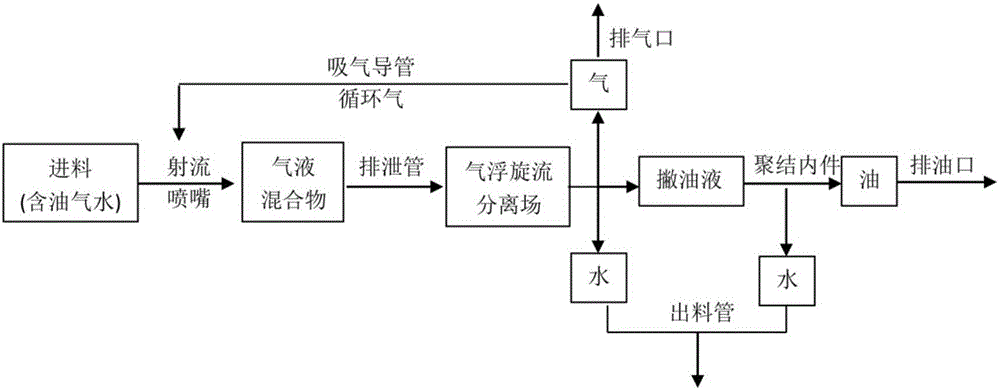

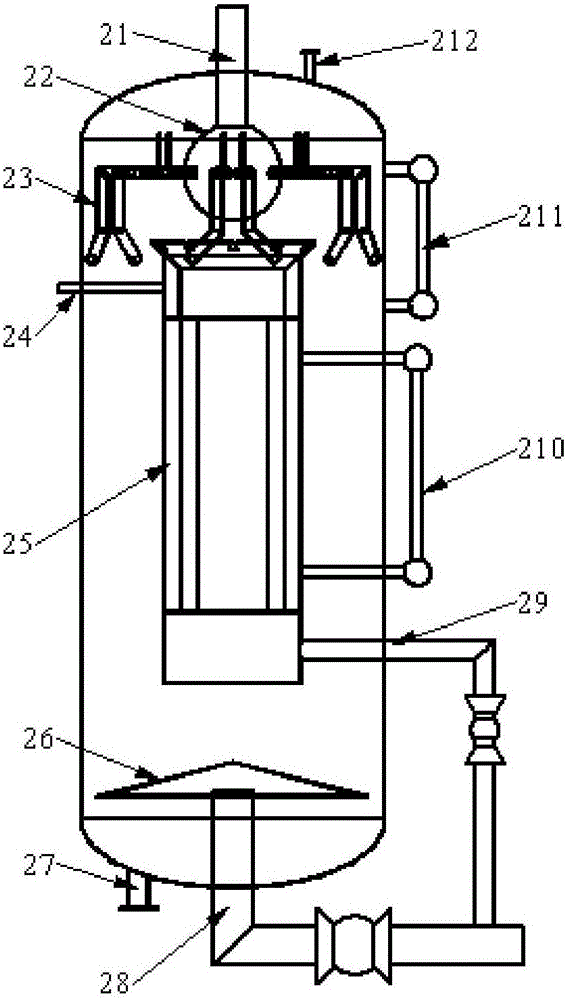

[0050] The sour water degassing and oil removal separation process in a petrochemical sulfur plant adopts the method and device of the invention for pilot test, and adopts single-stage treatment. Refer to the schematic diagram of the three-phase separation process. figure 1 , Refer to the device structure diagram Figure 2~5 :

[0051] The device includes a tank, a distributor 22, a jet drain 23, an inner cylinder 25 and a bottom baffle 26.

[0052] The diameter-to-height ratio of the tank is 1:2~1:3, with a feed port, an exhaust port 212, an oil discharge port, a mud discharge port 27, a discharge port 28, a coalescing outlet 29, a pressure control gauge, The liquid level gauge 211 and the inner cylinder interface level gauge interface 512.

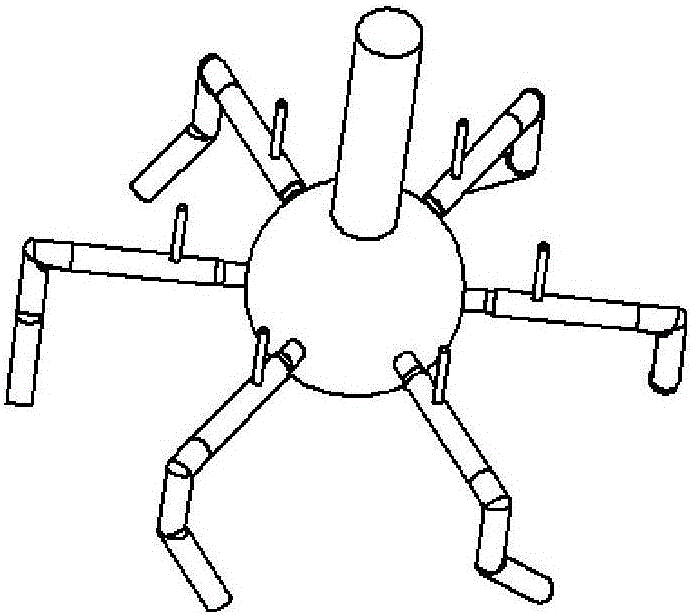

[0053] The distributor 22 has a spherical or polygonal prism shape, and the outlets are evenly distributed around the horizontal circumference.

[0054] The jet drain 23 includes a jet and a drain pipe 43. The jet is a jet nozzle 42 with a suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com