A functionally graded zirconia ceramic material partially infiltrated with dental glass

A technology of zirconia ceramics and functional gradient, applied in the application field of biomedical materials, can solve the problems of insufficient bonding force between zirconia ceramics and veneering porcelain, and achieve good biological compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

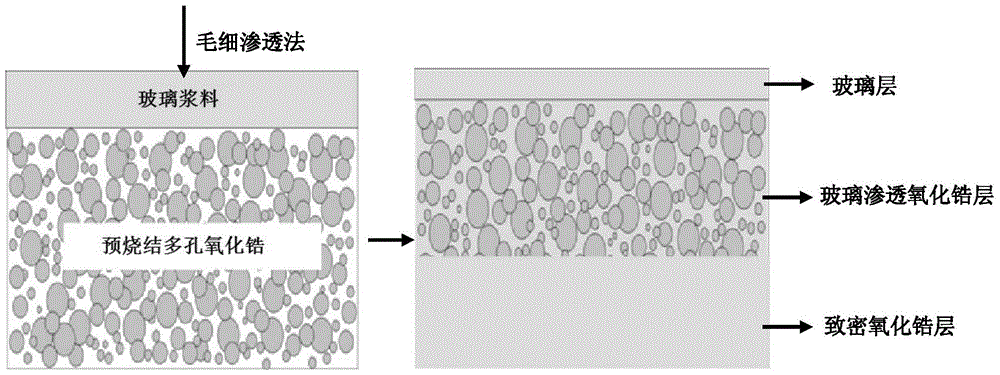

[0028] A method for preparing partially infiltrated functionally graded zirconia ceramic material for dental glass, such as figure 1 As shown, including the following steps:

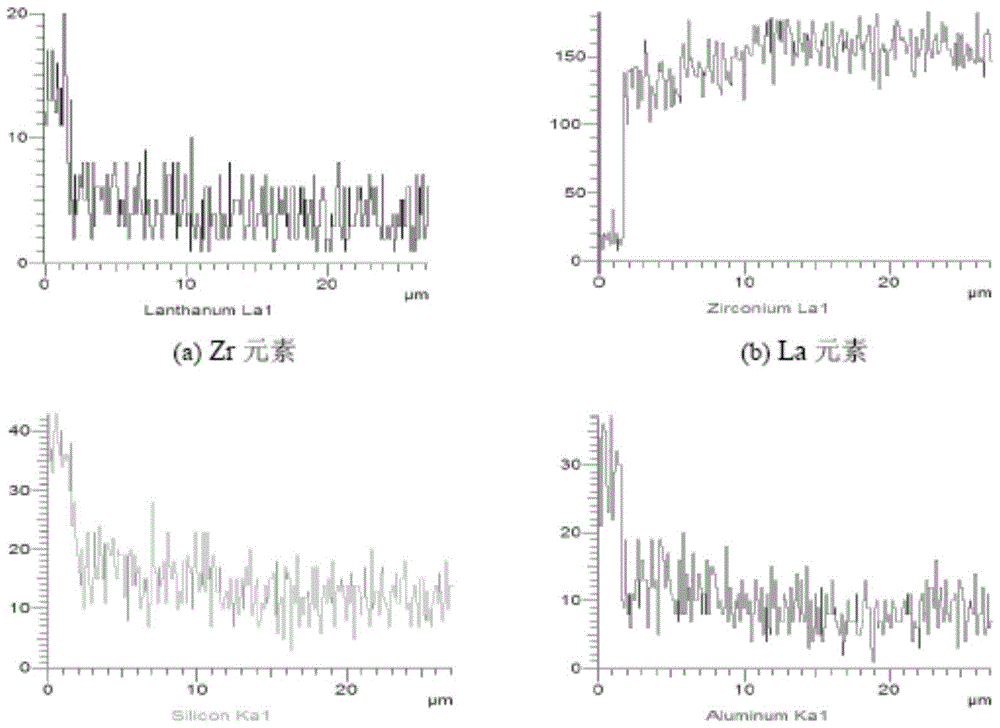

[0029] (1) Preparation of permeable glass material: according to formula La 2 O 3 15wt%, ZrO 2 5wt%, Y 2 O 3 5wt%, SiO 2 20wt%, B 2 O 3 15wt%, BaO 15wt%, Al 2 O 3 15wt%, TiO 2 4wt%, CaO 4wt%, CeO 2 1wt%, Fe 2 O 3 1wt%, weigh the powder of each component, put it into a ball mill tank, and use deionized water as the medium to ball mill for 6 hours and mix thoroughly; after ball milling, pour the slurry into a porcelain dish and dry it in an oven at 87°C for more than 24 hours until The moisture completely evaporates; put the powder into a platinum crucible, place it in a muffle furnace, heat up to 1300°C in an air atmosphere, keep it at a constant temperature for 2h, and cool to room temperature with the furnace; add the glass particles to a water ball mill according to a 2:1 ball-to-material ratio, After dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com