Textile having water-repellent front surface and close-fitting-resistant back surface, and production method thereof

A production method and technology for textiles, applied in the field of textiles, can solve the problems that clothes are uncomfortable against the body, affect the appearance of clothes, and reduce comfort, and achieve the effects of improving resistance to external liquids, improving wearing beauty, and improving breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

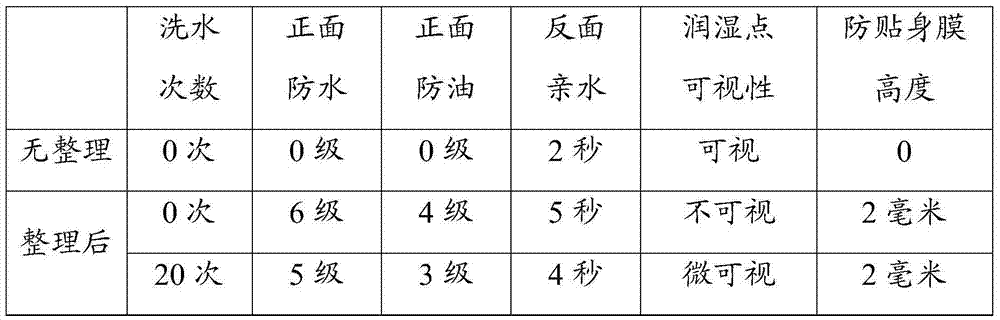

Embodiment 1

[0030] The production process of 32S pure cotton double-sided fabric with different functions of water repellency on the front, hydrophilic in the middle, and partial water repellency on the back: preparation of water repellent pulp; front water repellent coating; drying; preparation of anti-skin paste; reverse anti-skin coating; baked; finished product.

[0031] Pre-treatment: caustic soda 2g / L, refining agent 1.5g / L, hydrogen peroxide 2g / L, hydrogen peroxide stabilizer 0.5g / L100°C for 45 minutes;

[0032] Dyeing: 3RS0.5%, 3BS0.3% sodium sulfate 50g / L, sodium carbonate 20g / L, dyeing at 60 degrees for 45 minutes

[0033] Hydrophilic setting: The setting can ensure the width and weight of the textile, and lay a good foundation for subsequent finishing. At the same time, the hand feeling of the textile can be improved by adjusting the setting formula. In order to ensure the hydrophilicity of the textile, it is necessary to use a hydrophilic soft agent. The shaping formula and ...

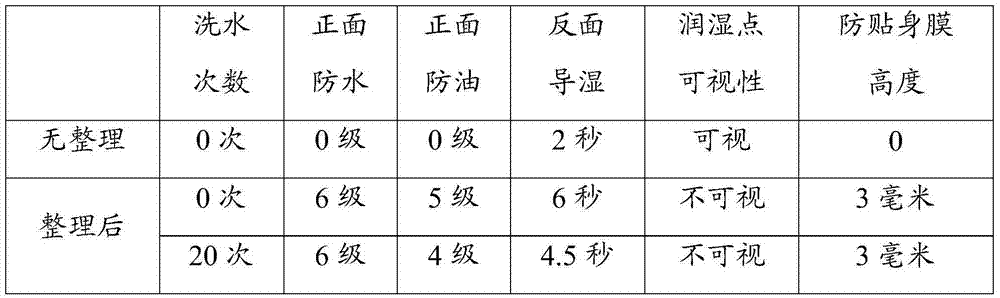

Embodiment 2

[0052] Production method of 100% polyester 75D mesh fabric with water-repellent front and anti-skin-resistant textiles on the back Production process: preparation of water-repellent slurry; front water-repellent coating; drying; preparation of anti-skin slurry; reverse anti-skin coating; baking; finished product .

[0053] Pre-treatment: degreaser 2g / L, dispersant and chelating agent 1g / L, penetrant 0.5g / L at 80°C for 20 minutes;

[0054] Dyeing: disperse red E-4B0.35%, yellow SE-4RL0.45%, blue E-4R0.5%, dyeing at 130 degrees for 45 minutes;

[0055] High-temperature hydrophilic setting: setting can well ensure the width and weight of textiles, and lay a good foundation for subsequent finishing. At the same time, the hand feeling of textiles can be improved by adjusting the setting formula. In order to ensure the hydrophilicity of textiles, it is necessary to use hydrophilic softener. The shaping formula and process are as follows: penetrant 1g / L, acetic acid 0.5g / L, hydroph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com