Special vibrating screen for sulfur-contained oil and gas field

A vibrating screen and oil and gas field technology, which is applied in wellbore/well components, earthwork drilling, construction, etc., can solve the problems of human safety and inapplicability that are easy to endanger the operator, and achieve the goal of reducing poisoning incidents, improving efficiency, and stabilizing nitrogen gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

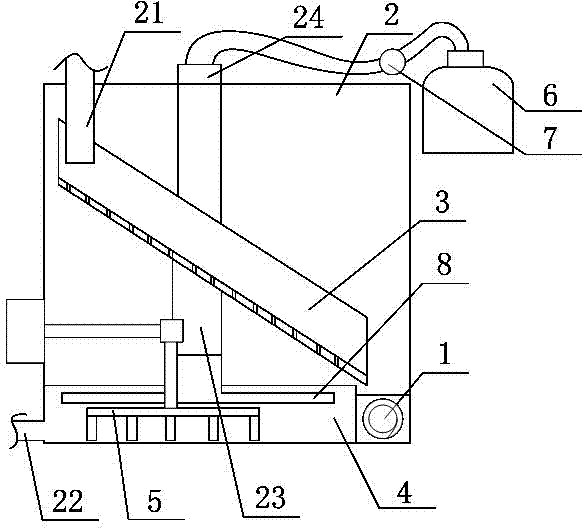

[0027] A special vibrating screen for sulfur-containing oil and gas fields, such as figure 1 , figure 2 As shown, it includes a closed box 2 with a feed port 21, a discharge port 22, an air return pipe 23 and an air outlet pipe 24;

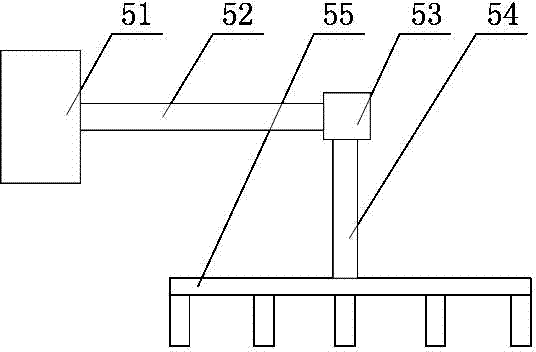

[0028] Described airtight box 2 inside is equipped with the vibrating screening net 3 that tilts to set, collection pool 4, agitator 5 and spiral chip conveyor 1; 51 connection, the other end extends into the main connecting rod 52 in the airtight box 2, the steering gear 53 installed on the other end of the main connecting rod 52, and the stirring rod 55 connected to the steering gear 53 through the secondary connecting rod 54;

[0029] The collection pool 4 is located directly below the vibrating screening net 3, the stirring rod 55 is located in the collecting pool 4, and the spiral chip conveyor 1 is installed directly below the lowest end side of the vibrating screening net 3; Right above the side of the highest end of the screen 3 , the d...

Embodiment 2

[0035] In this embodiment, on the basis of Embodiment 1, a one-way valve 7 and a gas storage tank 6 are added, and the specific setting method is as follows:

[0036] The air return pipe 23 is provided with a one-way valve 7 . One end of the one-way valve 7 communicates with the gas return pipe 23, and the other end of the one-way valve 7 communicates with the gas storage tank 6, and the gas stored in the gas storage tank 6 in this embodiment is nitrogen.

[0037] In the present invention, nitrogen gas is used to fill the recovered slurry, and then the hydrogen sulfide gas in the recovered slurry is discharged, and then when the gas flowing out of the step (3) of Example 1 is discharged into the atmosphere after removing the hydrogen sulfide gas, it can effectively prevent Air pollution and effective cost savings.

Embodiment 3

[0039] The only difference between this embodiment and Embodiment 1 or 2 is that one end of the air return pipe 23 extending into the collection tank 4 is also provided with a distributing device 8, which is disc-shaped and has a Air inlet and more than two air distribution holes. In this embodiment, there are 10 gas distribution holes, which are evenly distributed on the disk-shaped gas distribution device 8 .

[0040] Through the arrangement of the gas distributing device, the gas charged into the recovered slurry is effectively evenly dispersed in it, thereby improving the precipitation efficiency of hydrogen sulfide gas.

[0041] In order to compare the desulfurization effect of the present invention, the present invention provides a control group, and its specific operation steps are as follows: on the basis of Example 1, the step of stirring the recovered slurry in the collection tank by the stirring device is removed, and simultaneously No inert gas is introduced.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap