An antifreeze and heat preservation system for tunnels in cold regions and a construction method for antifreeze and heat preservation

A technology for tunnels and thermal insulation systems in cold regions, which is used in tunnels, tunnel linings, and earth-moving drilling and mining to achieve the effects of easy quality control, uniform load distribution, and convenient construction and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

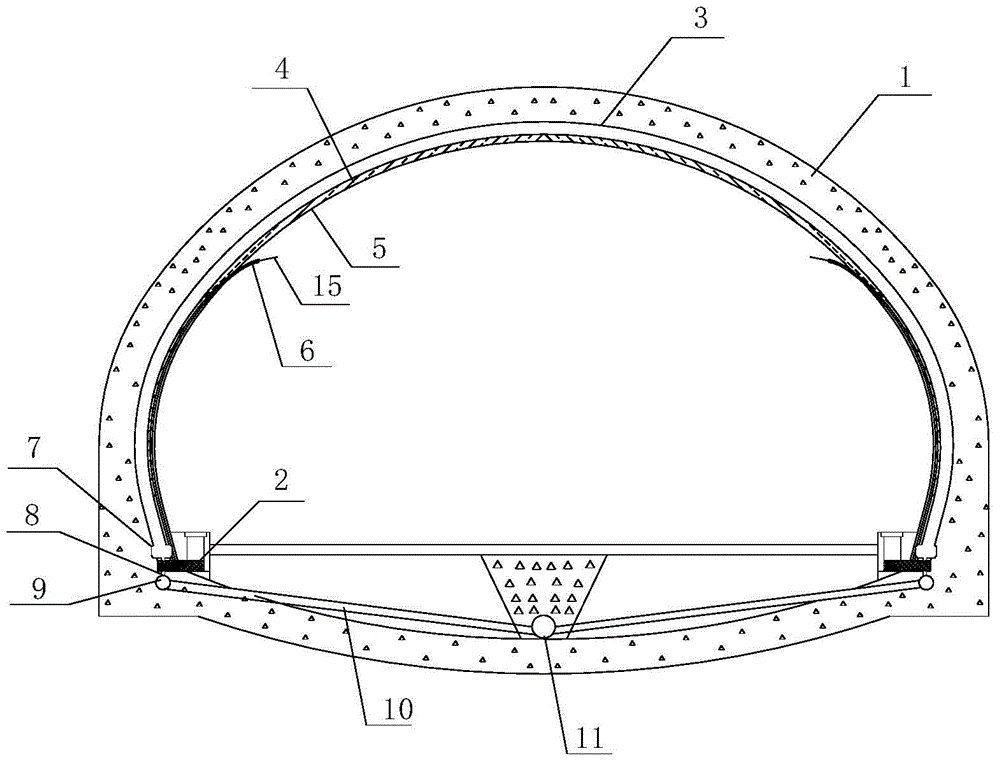

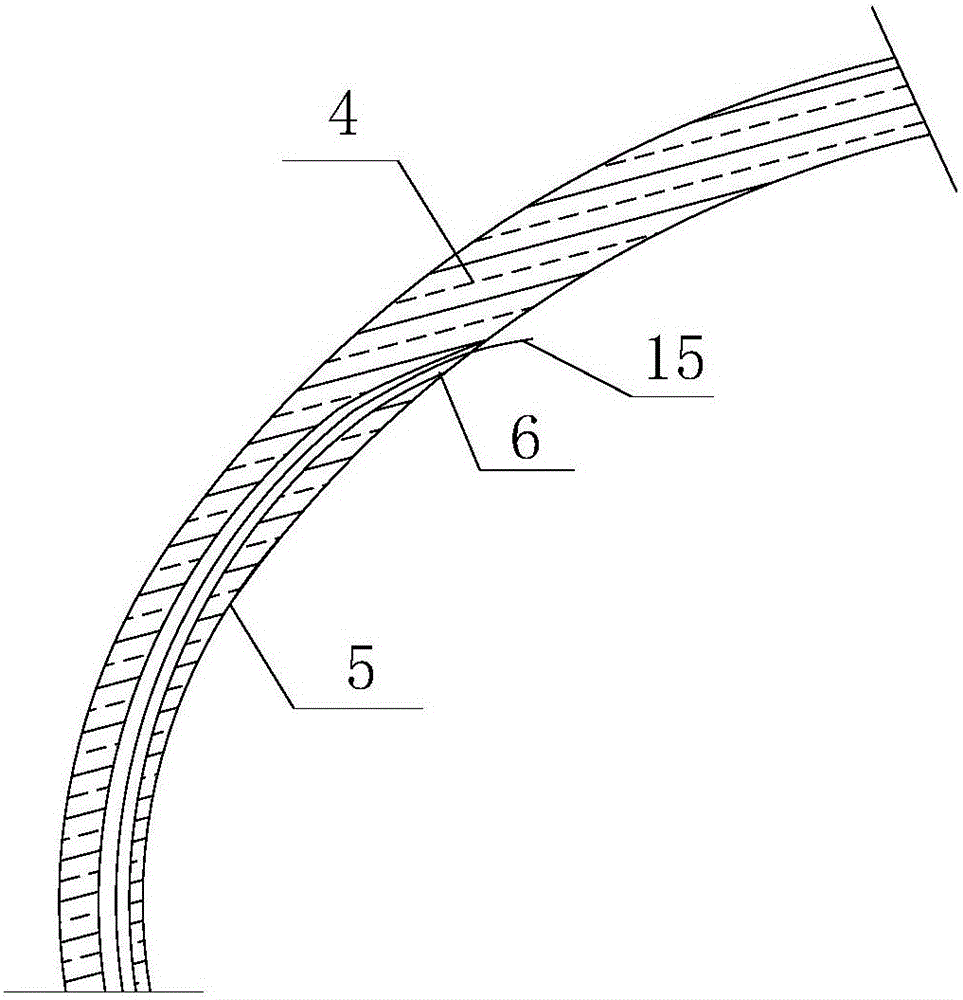

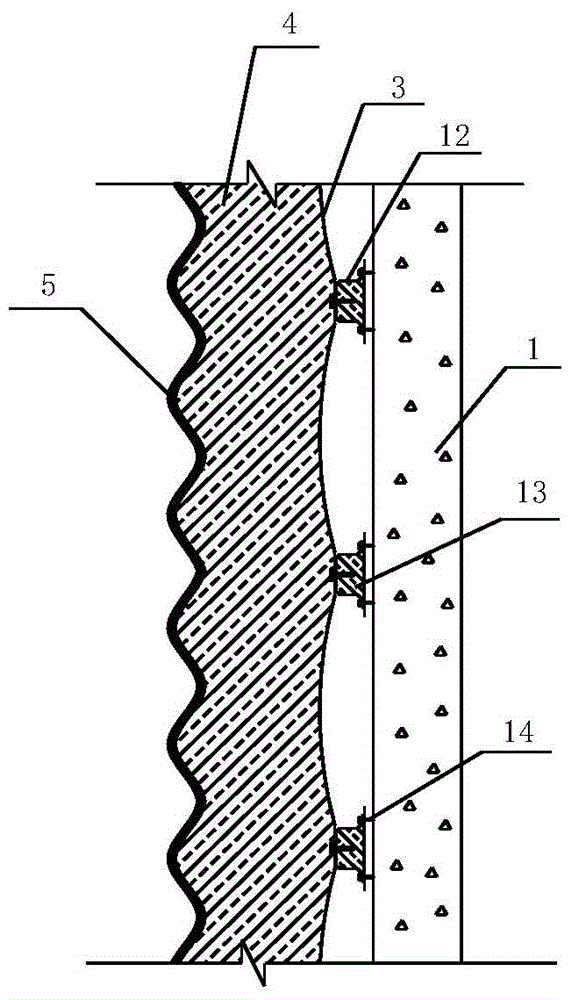

[0039] Below in conjunction with accompanying drawing and specific embodiment structure of the present invention and construction method thereof are described in further detail:

[0040] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , an antifreeze and thermal insulation system for tunnels in cold regions mainly consists of concrete base 2, aluminum film 3, lightweight aggregate thermal insulation concrete 4, steel corrugated board 5, PVC pipe 6, aluminum alloy water collection tank 7, vertical drainage pipe 8, longitudinal drainage Pipe 9, horizontal drainage pipe 10, central drainage ditch 11, aluminum alloy keel frame 12, lightweight fiber cement mortar 13, self-tapping screws 14, electric heating belt 15, etc.

[0041] see image 3 as well as Figure 4 , the aluminum film 3 is set on the outside of the secondary lining 1 of the tunnel, and is fixed on the outside of the secondary lining 1 of the tunnel by using the aluminum alloy keel frame 12 and light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com