Pumped storage thermodynamic system of thermal power plant

A technology of pumped storage and thermal systems, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve throttling loss, large thermal shock of thermal system, system operating efficiency, operating stability, economy, and safety Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

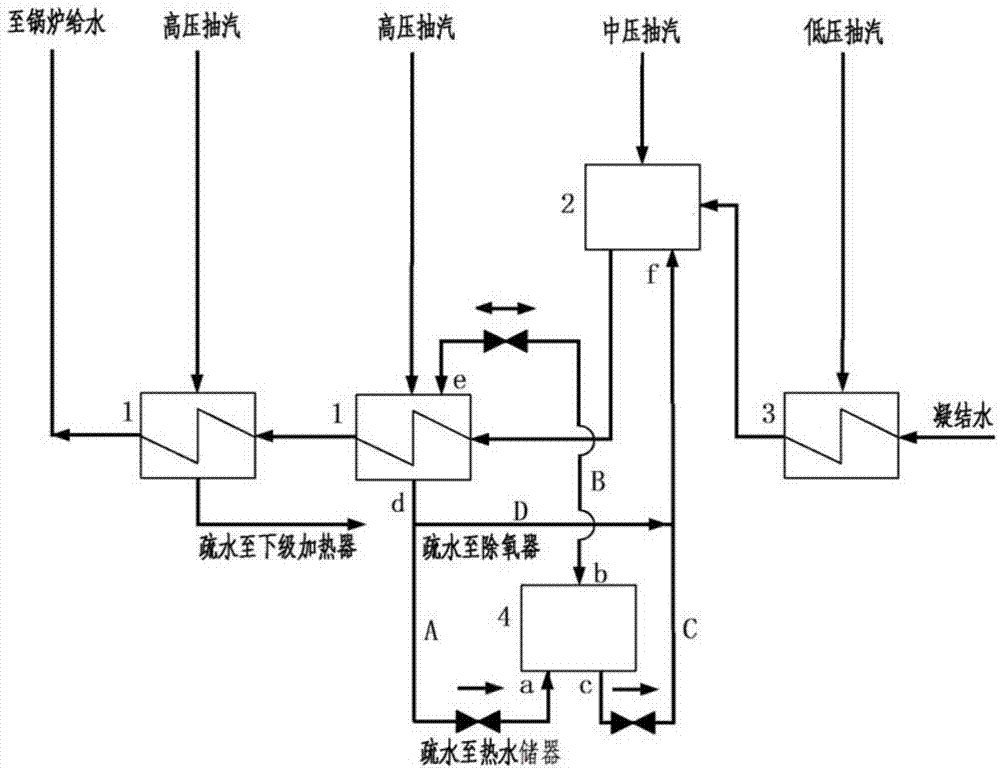

[0124] Embodiment 1 The pumped storage thermal system of the local feedwater heater draining water

[0125] image 3 Shows the pumped storage thermal system flow of the local heater drain, as follows: When the frequency of the power grid is too high and the output of the unit needs to be reduced, part of the drain of the primary feedwater heater (3# high addition) is arranged according to the existing thermal system It is discharged into the deaerator, and the other part of the water enters the newly configured hot water reservoir, through which the heat of a part of the water in the original thermal system is collected and stored. At this time, the flow rate of hydrophobic water entering the deaerator from 3# is reduced. In order to ensure the constant main steam flow rate, the condensed water volume needs to be increased, and the corresponding steam volume required by the condensed water heater and deaerator to heat the condensed water increases. As a result, the amount of ...

Embodiment 2

[0129] Example 2 Pumped-storage thermodynamic system for water-draining of feedwater heaters adjacent to the machine

[0130] Figure 4 Showing the pumped storage thermodynamic system for water drainage of adjacent machine heaters: part of the water is drawn from the adjacent unit’s supercharger to the hot water storage, and when the frequency of the grid is too low, the hot water is transferred to The water in the reservoir is drained into the deaerator of the machine to increase the heat source of the deaerator, thereby reducing the inlet medium-pressure steam extraction flow, allowing more steam to enter the low-pressure cylinder to do work, increasing the output of the unit, and increasing the grid frequency.

[0131] result

[0132] According to calculations, using the pumped storage thermal system of Example 2, if the heat of the low-parameter adjacent unit is transferred to the system of the high-parameter unit, the utilization rate of the heat in the high-parameter hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com