Heat balance structure for saturated water generation device

A generating device and heat equalization technology, applied in steam generation, lighting and heating equipment, components of steam boilers, etc., can solve problems such as large environmental pollution, high technical requirements, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with embodiments.

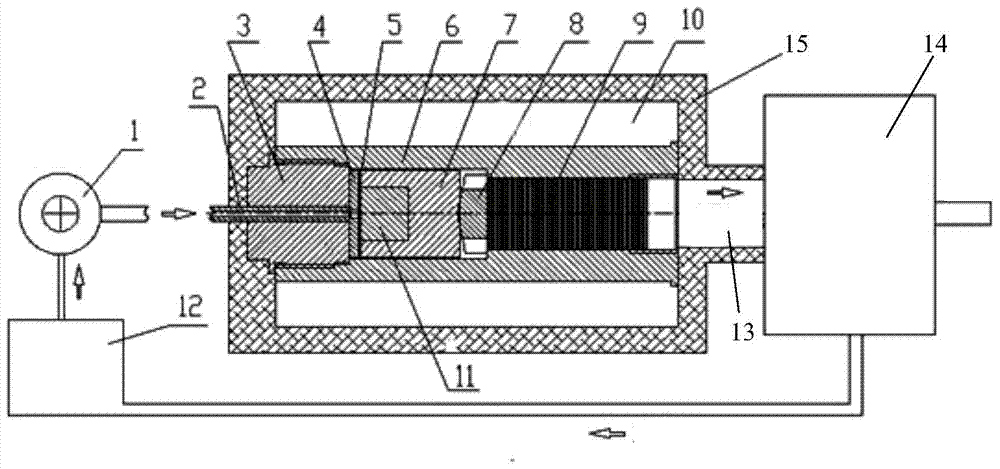

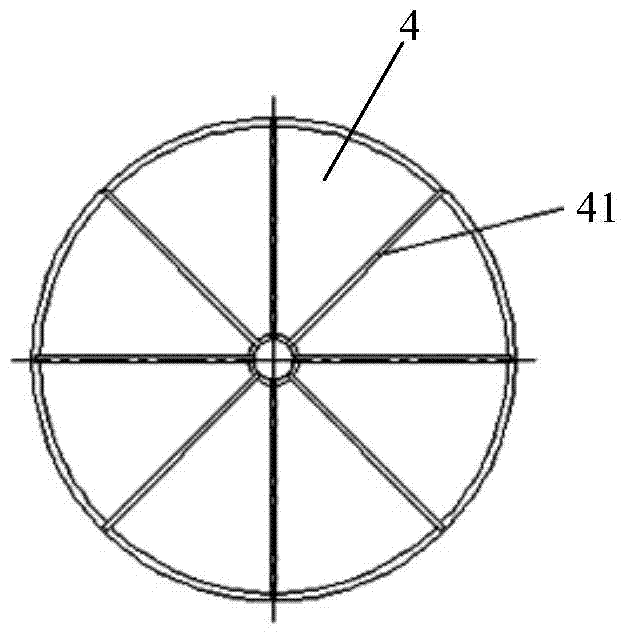

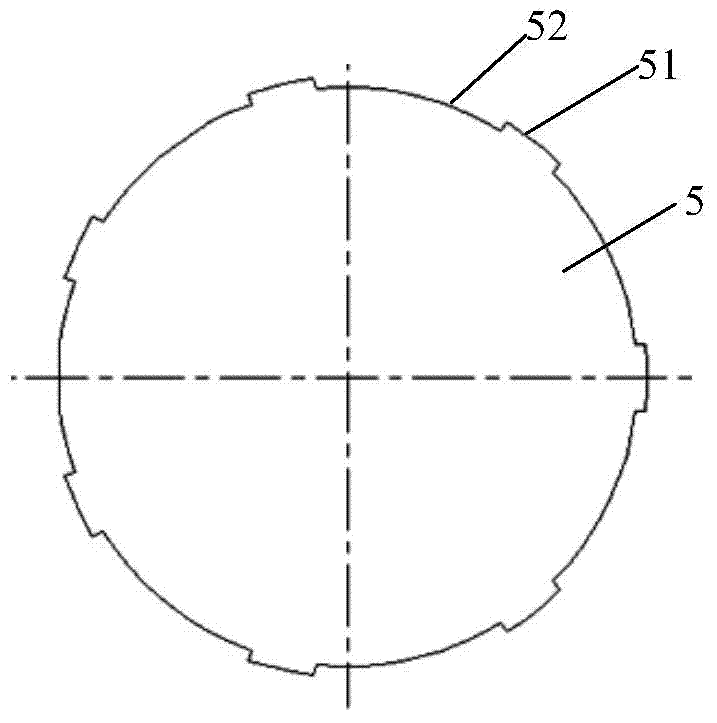

[0015] The invention discloses a steam power generation system, which comprises a saturated water generating device and a saturated water explosion device. like figure 1 As shown, the system includes a thin water inlet tube 2 , a screw plug 3 , a splitter 4 , a baffle 5 , a heat receiver 6 , a column 7 , a base 8 , a heat source 10 and a heat conductor 11 .

[0016] The water inlet thin tube 2 is embedded in the screw plug 3, and the screw plug 3 is connected to the heat receiver 6 through threads, and at the same time, the splitter plate 4 and the baffle plate 5 are generated. The other end surface of the baffle plate 5 is connected to the cylinder 7 and the heat conductor 11 according to the pre-tightening pressure.

[0017] The heat conductor 11 is embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com