Thermal ageing assessment method of cast austenitic stainless steel of CPR1000 nuclear power plant

A technology of austenitic stainless steel and heat aging, which is applied in the direction of material inspection products, test metals, etc., can solve the problems of material fracture toughness decline, heat aging embrittlement, etc., and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below.

[0021] The thermal aging evaluation method of CPR1000 nuclear power plant casting austenitic stainless steel of the present invention, it comprises the following steps:

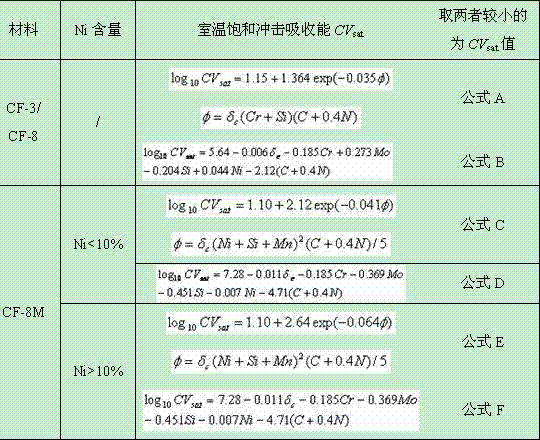

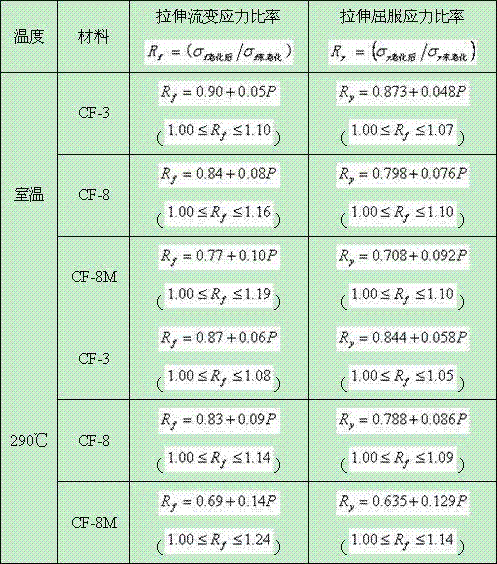

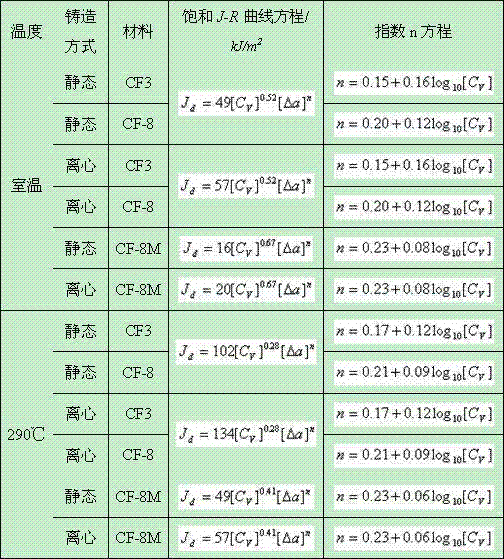

[0022] (a) Take the austenitic stainless steel on the equipment / components in the CPR1000 nuclear power plant for elemental analysis, and calculate the equivalent chromium content Cr eq and ferrite content δ c , to evaluate the thermal aging sensitivity of austenitic stainless steel;

[0023] Specifically: (a1) Take the austenitic stainless steel on the equipment / parts of the CPR1000 nuclear power plant for elemental analysis, determine the mass content of Cr, Mo, Si, Ni, Mn, N and C, and use each element in the calculation formula The symbol indicates its mass content;

[0024] (a2) Use formula 1 to calculate the equivalent chromium content Cr eq , Using formula 2 to calculate the equivalent nickel content Ni eq ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com