High-performance rotation motor with high starting torque and low starting current

A technology of starting torque and starting current, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of increased temperature rise of motor windings, small starting torque, soft mechanical characteristics, etc., and achieves improved starting ability and low starting current Reduces the effect of hard mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

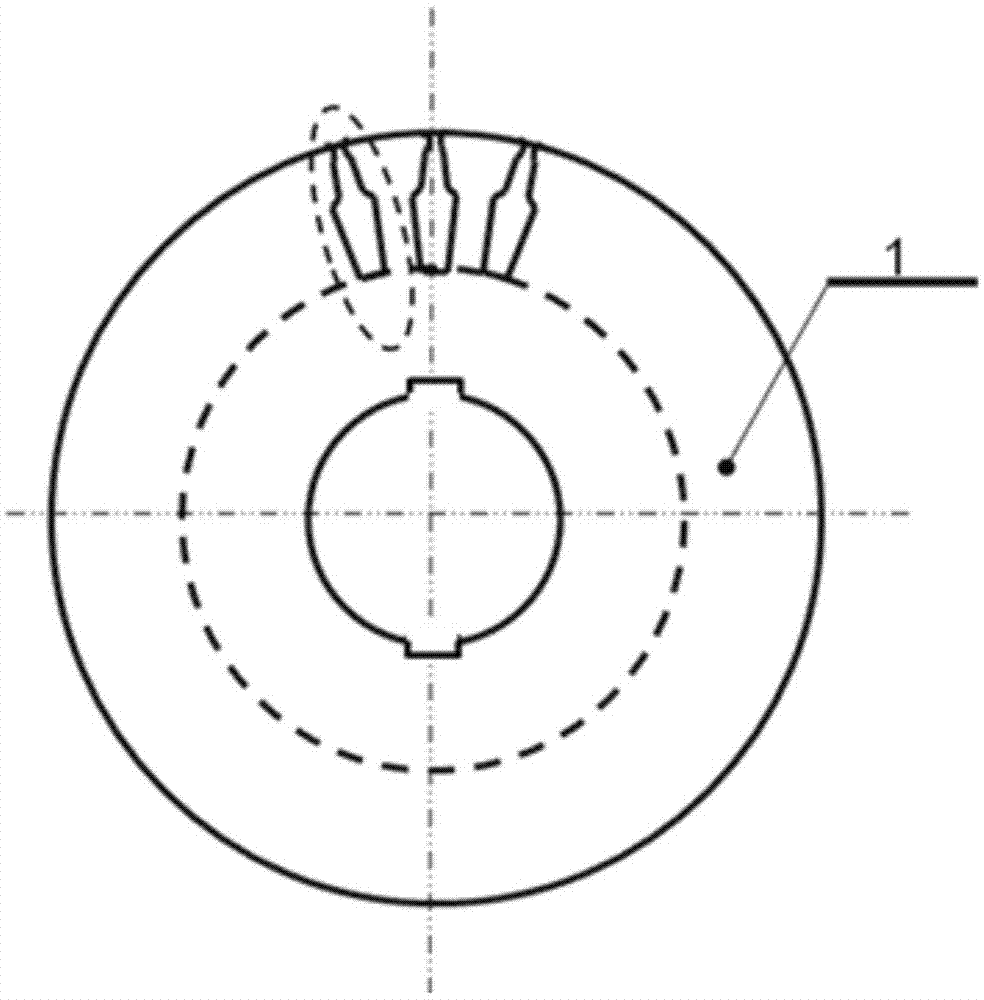

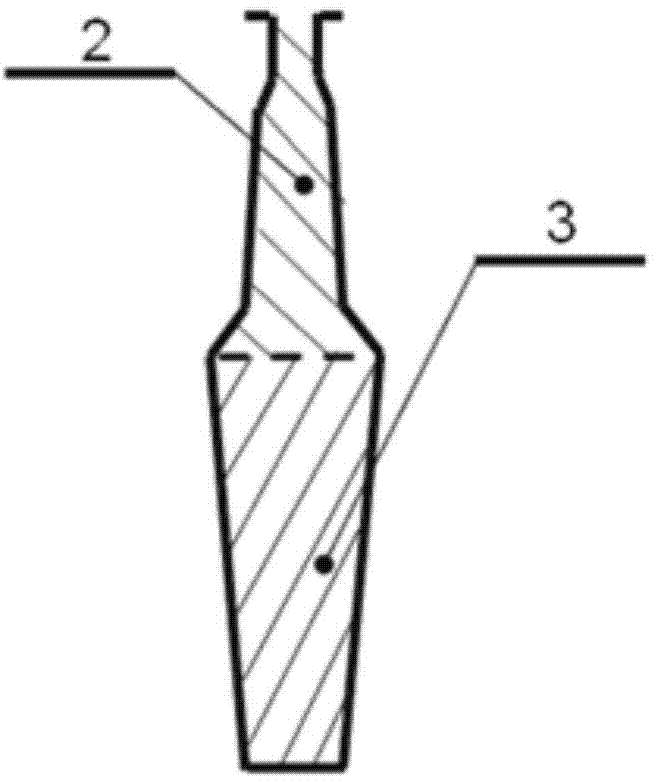

[0010] A high-starting torque, low-starting current high-performance rotary motor, the motor is composed of a stator and a rotor. figure 1 As shown, in the figure (1) is the rotor punch, (2) is the high resistivity material of the rotor circuit, (3) is the low resistivity material of the rotor circuit, the resistivity of the high resistivity material (2) is (9.5~10 )×10 -8 (Ωm), the resistivity of the low resistivity material (3) is (2.73~3)×10 -8 (Ωm), the two materials are combined to form a whole with a metallurgical structure. When the motor starts, due to the skin effect, most of the rotor current flows through the high resistivity material located on the outer circle of the rotor. According to the starting principle of the motor, the resistance increases , the starting torque increases and the starting current decreases, so that a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com