Method, processing device and processing system for automated surface processing of shaped large components of wind energy installations

A technology for processing equipment and large components, applied in metal processing equipment, control of workpiece feed movement, wind power generation, etc., can solve problems such as inability to process equipment, complex large components, and complex rotor blade shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

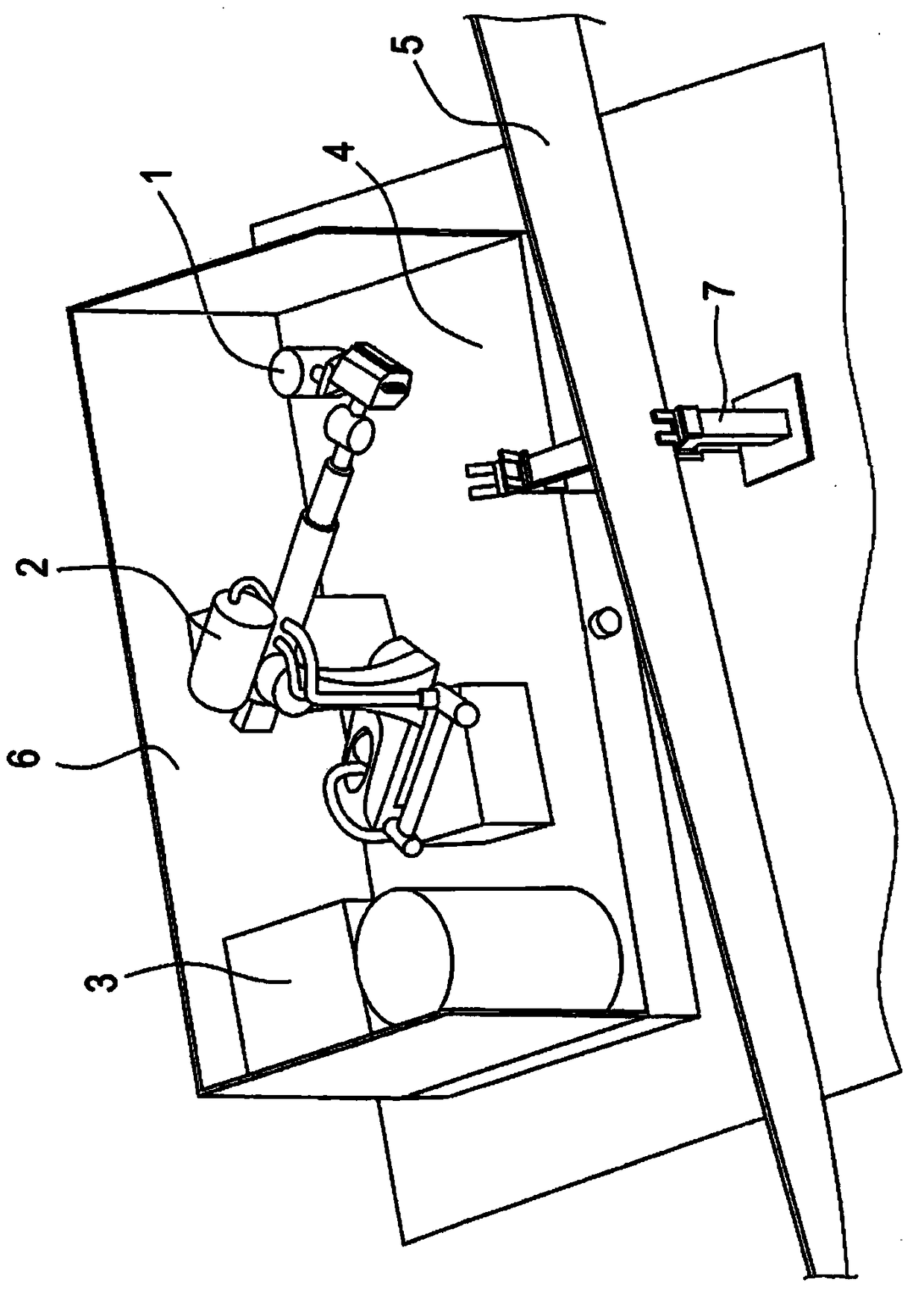

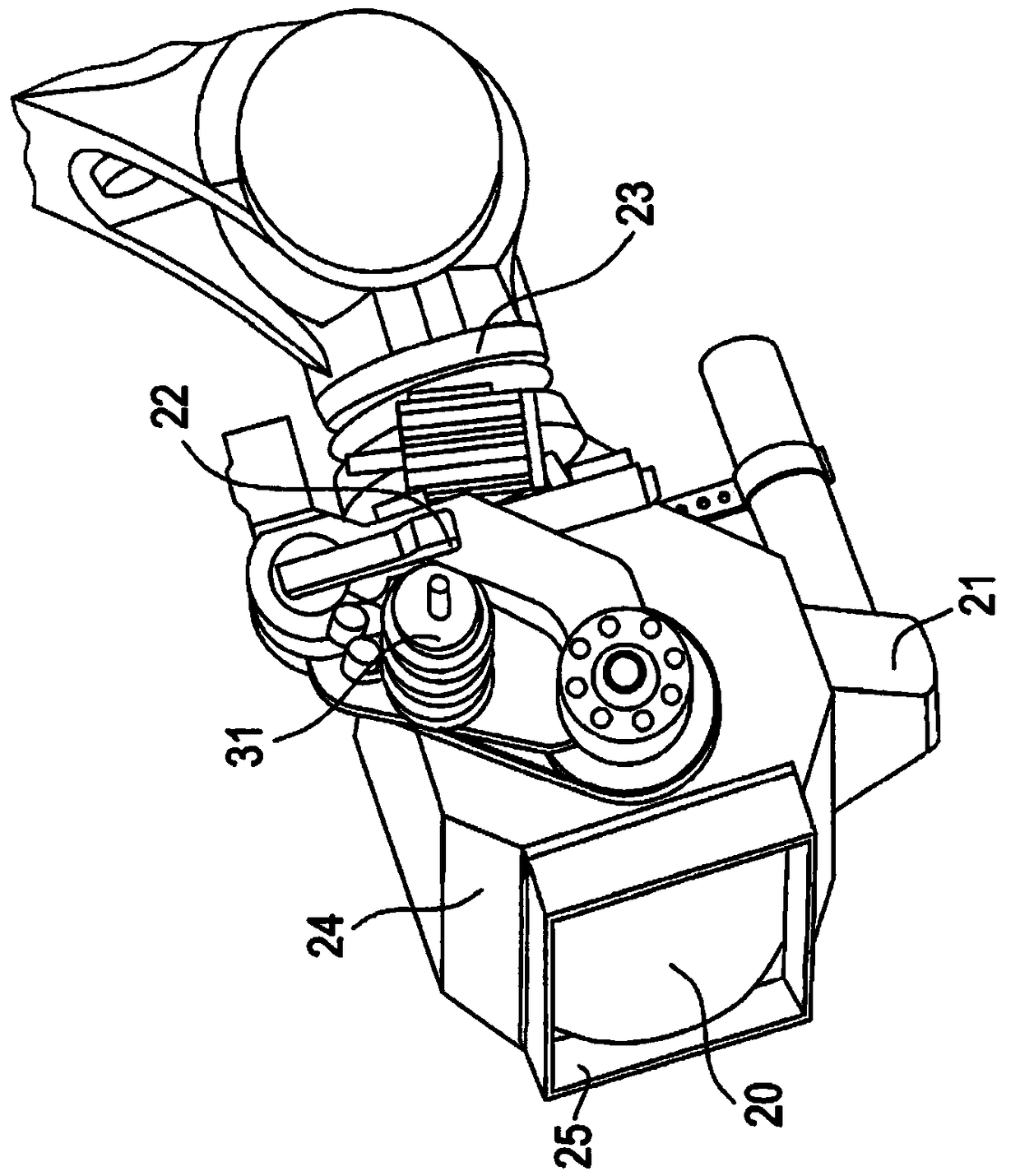

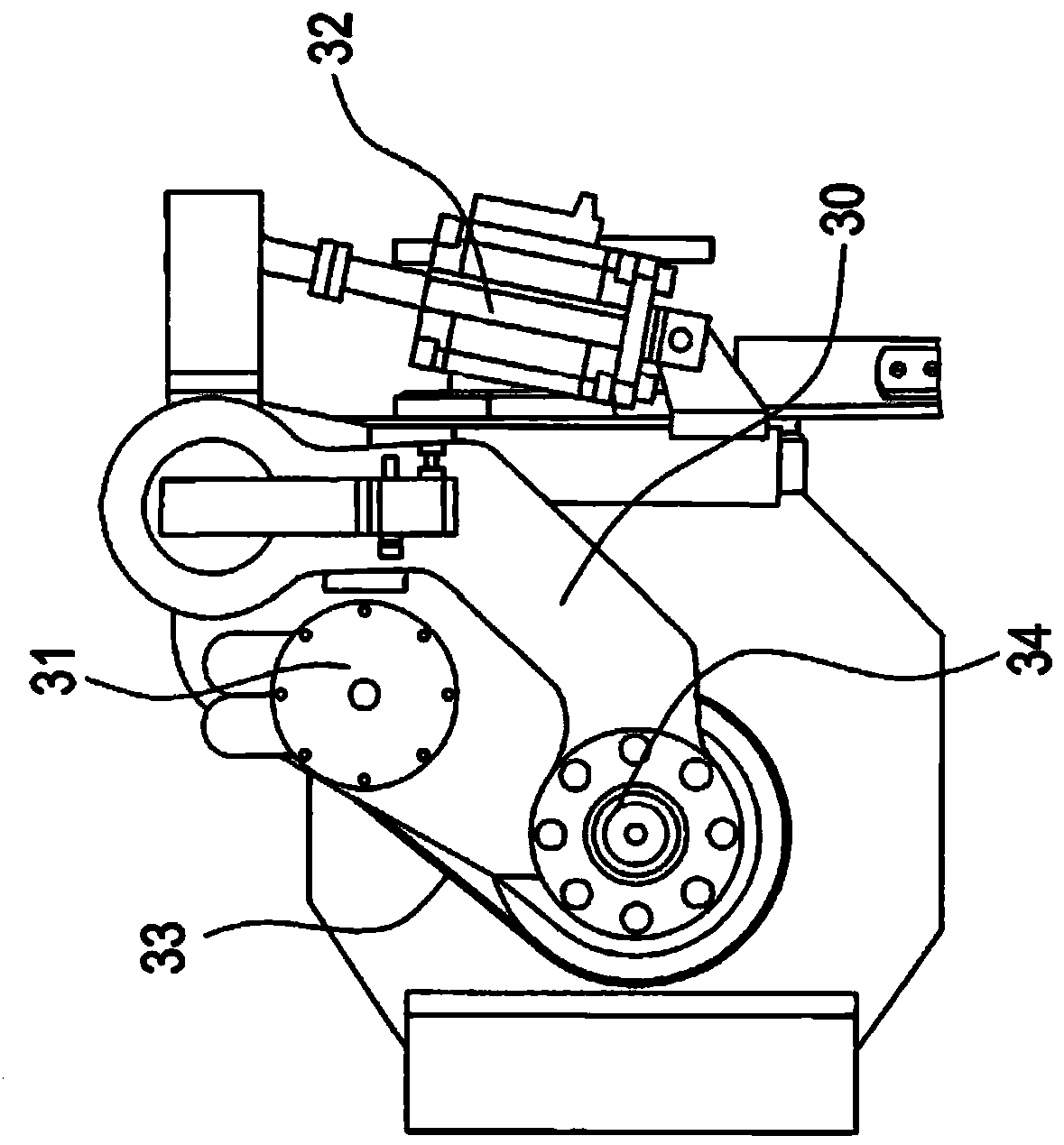

[0051] exist figure 1 The device for grinding rotor blades for wind energy installations shown in , consists of a grinding robot 2 on whose arm a grinding head 1 is mounted. The grinding robot 2 and the suction container 3 are mounted on a mobile carriage 4 . The entire device is surrounded by a protective cover 6 for reasons of work safety, so that no personnel can enter the carriage during operation. The mobile carriage 4 can be turned in any desired direction via a remote control, which can also be designed as a radio remote control. The grinding head is rotatably mounted on the head of the grinding robot 23 .

[0052] Basic structure:

[0053] The entire processing system in the form of a grinding facility actually consists of three components (i) a robot 2 comprising a grinding head 1 mounted on a mobile carriage 4; (ii) a mobile carriage 4 which moves The carriage has control means for the robot 2 and suction means 21 for the dust of the grinding unit and the entire ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap