Antibacterial porous ceramic tile, and preparation method therefor

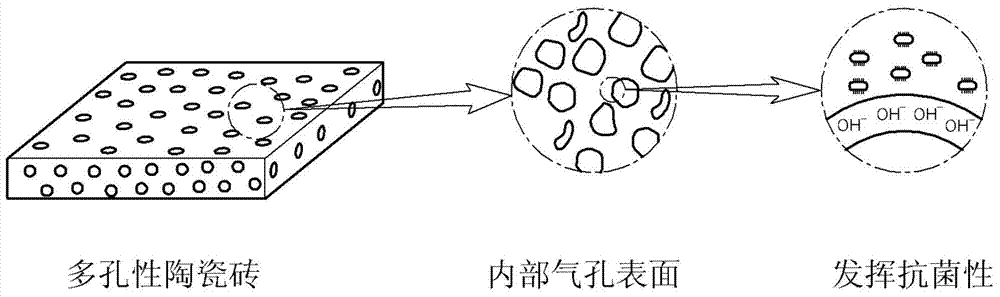

A manufacturing method and technology for ceramic tiles, which can be applied to ceramic products, clay products, other household appliances, etc., can solve the problems of detachment of antibacterial substances, reduce moisture absorption and moisture resistance, difficult to apply porous ceramic tiles, etc., so as to reduce the generation of floating microorganisms, Effects of suppressing reproduction and improving convenience and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

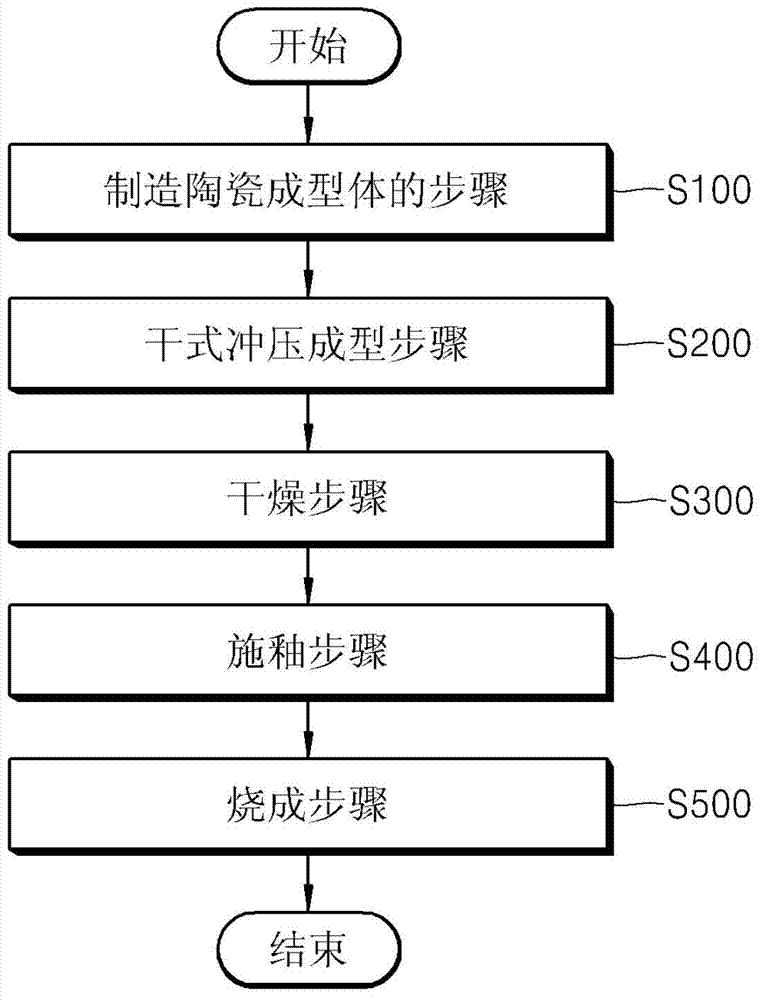

[0069] The mixture described in the following Table 1 was pulverized by a ball mill, and the obtained slurry was spray-dried to obtain uniformly mixed spherical particle powder with a moisture content of 8% and an average particle size of 300 μm.

[0070] Next, the above-mentioned granular powder was subjected to dry press molding to manufacture porous ceramic tiles with a length, height, and thickness of 7 cm, 7 cm, and 0.6 cm, respectively. Next, after drying the above porous ceramic tiles in a continuous drying furnace at 250°C, glass frit powder and pigment with an average particle size of 15um and a refractoriness of 750°C were dispersed in water and glazed by spraying.

[0071] Finally, the glazed porous ceramic tiles were put into a continuous gas furnace (RHK) and thermally decomposed at a temperature of 850° C. for 10 minutes to produce porous ceramics with an average diameter of pores of 5 nm and a porosity of 45%. brick.

experiment example

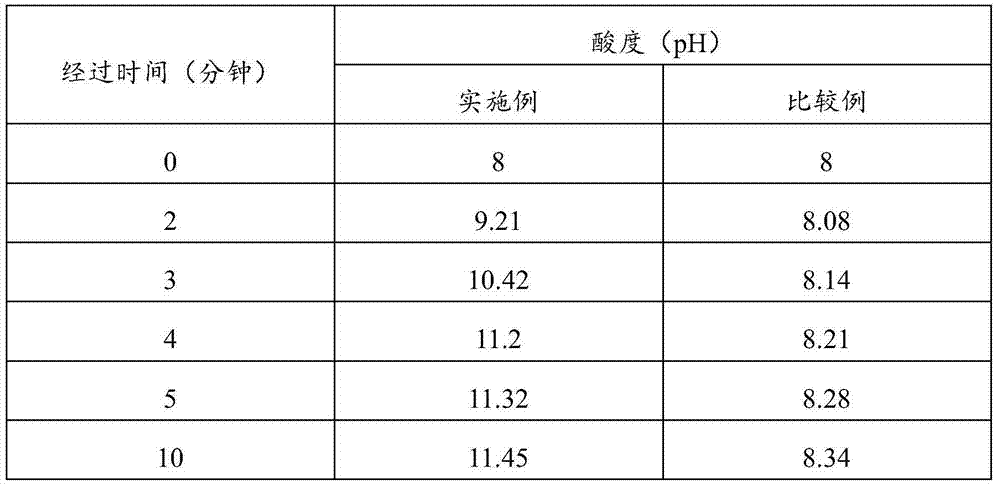

[0077] Experimental example: pH measurement of porous ceramic tiles

[0078] The porous ceramic tiles of the above examples and comparative examples were soaked in 25° C. water (100 ml) for 10 minutes. Thereafter, ions are present in the pores included in the porous pores as time passes. At this time, the pH was measured by measuring the acidity (pH) with a pH meter, and the results are shown in Table 2 below.

[0079] Table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com