Carbon-free trolley adaptable to S-shaped path with rods spaced from one another by different distances

A carbon-free car, suitable for different technologies, applied in toy cars, toy transmission, toys and other directions, can solve problems such as complex structure, achieve the effect of simple and reliable operation, easy disassembly and debugging, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

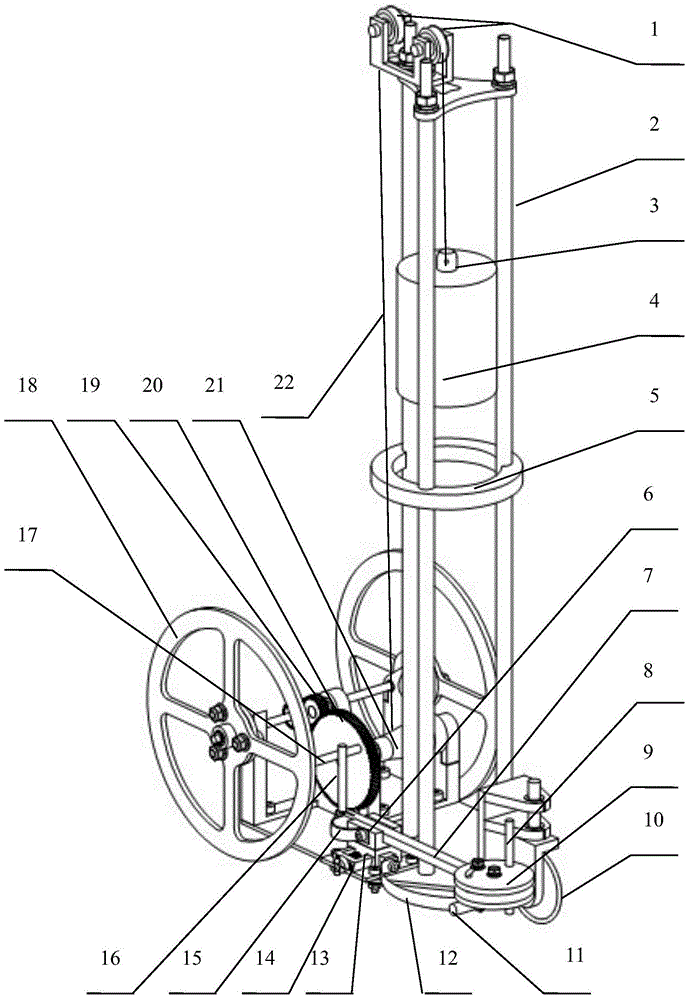

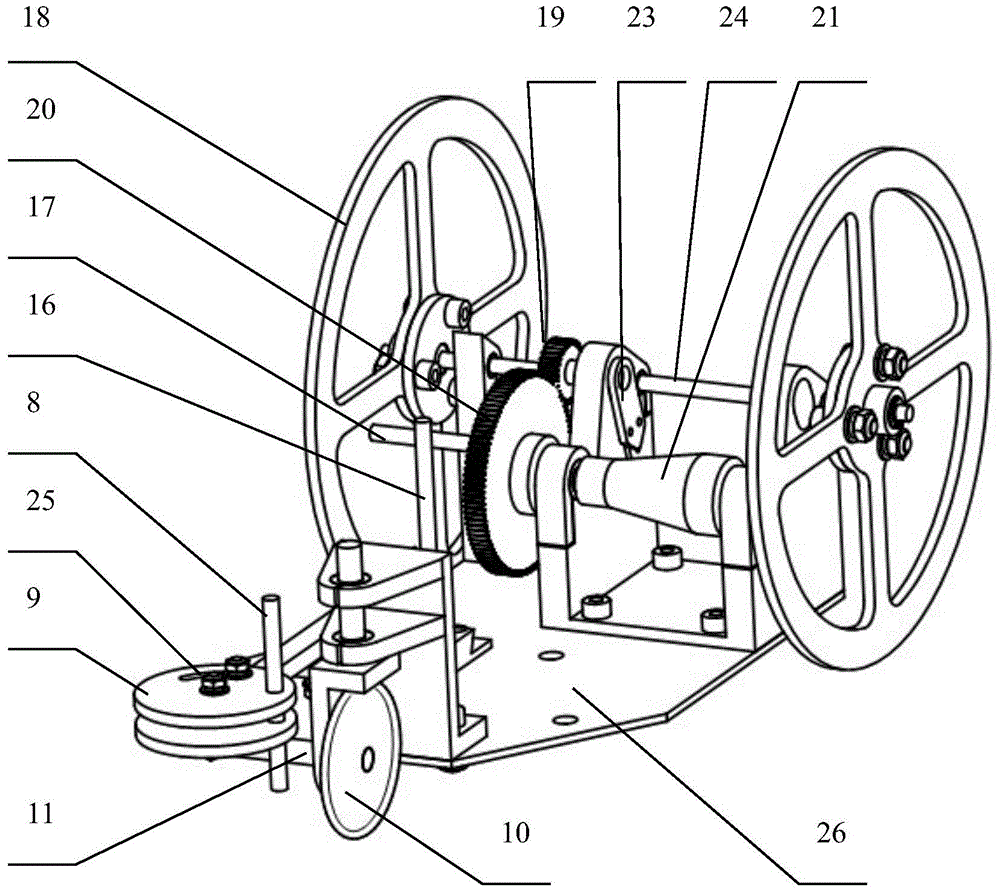

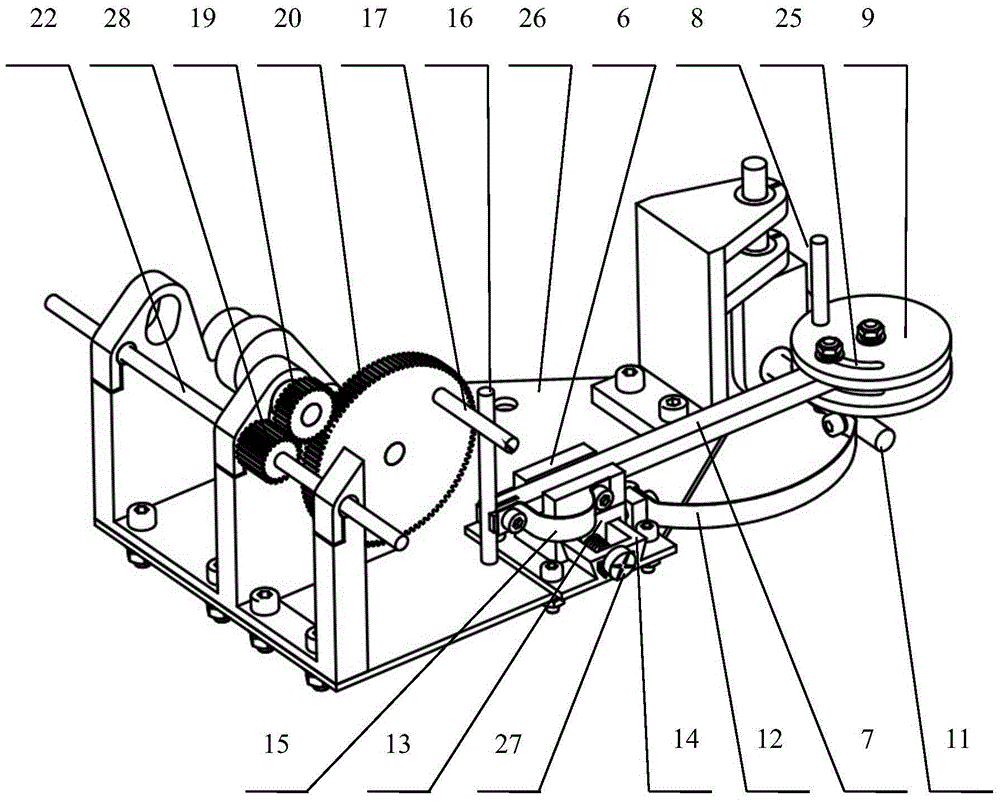

[0027] Such as figure 1 As shown, the carbon-free trolley that can adapt to the S-shaped path of different pole distances, its three columns 2 are assembled on the bottom plate 26 of the car body (referring to figure 2 ), the tops of the three columns 2 are pulley seats, and two pulleys 1 are placed on the pulley seats. The heavy object 4 is lifted to a certain height, tied on the flexible wire rope 22 through the hook 3, and the flexible wire rope 22 is wound on two On the pulley 1, be tied on the wire wheel 21 of car body bottom again, the flexible wire rope 22 that is long enough is wound around the wire wheel 21, so that the flexible wire rope 22 that is wound on the wire wheel 21 can drive the wire when the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com