A distiller

A technology of distiller and evaporator, which is applied in the field of distiller, can solve the problem that the liquid cannot be fully stirred, and achieve the effects of saving resources, receiving heat evenly, and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the drawings.

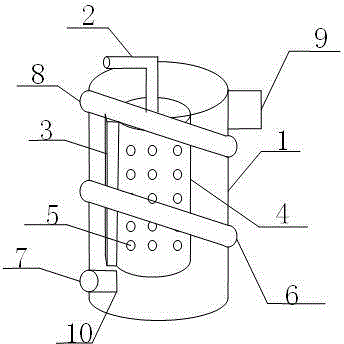

[0013] The present invention discloses a distiller, which includes a distiller body 1, a feed pipe 2 and a rotating scraper 3 in the evaporator, and is characterized in that: a rotatable is provided below the feed port of the feed pipe 2 The uniform cloth barrel 4 is provided with small holes 5 distributed on the uniform cloth barrel 4, the outer wall of the distiller body 1 is provided with an annular half pipe 6, and the annular half pipe 6 is provided with a steam inlet 7 and steam At the outlet 8, a cylindrical gas-liquid exchange device is fixed on the scraper support. A cylindrical condenser 9 is installed in the gas-liquid exchange device, and the outside of the gas-liquid exchange device is surrounded by a cylindrical heater 10.

[0014] Preferably, the annular half pipe 6 is spirally arranged on the outer wall of the still body 1.

[0015] Preferably, the steam inlet 7 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com