Automatic adjustment type auxiliary supporting mechanism for tool die

An automatic adjustment, tooling and mold technology, applied in the field of mechanical processing, can solve the problems of damaged workpiece positioning, low efficiency, high labor intensity, etc., and achieve the effect of improving support rigidity, high efficiency, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

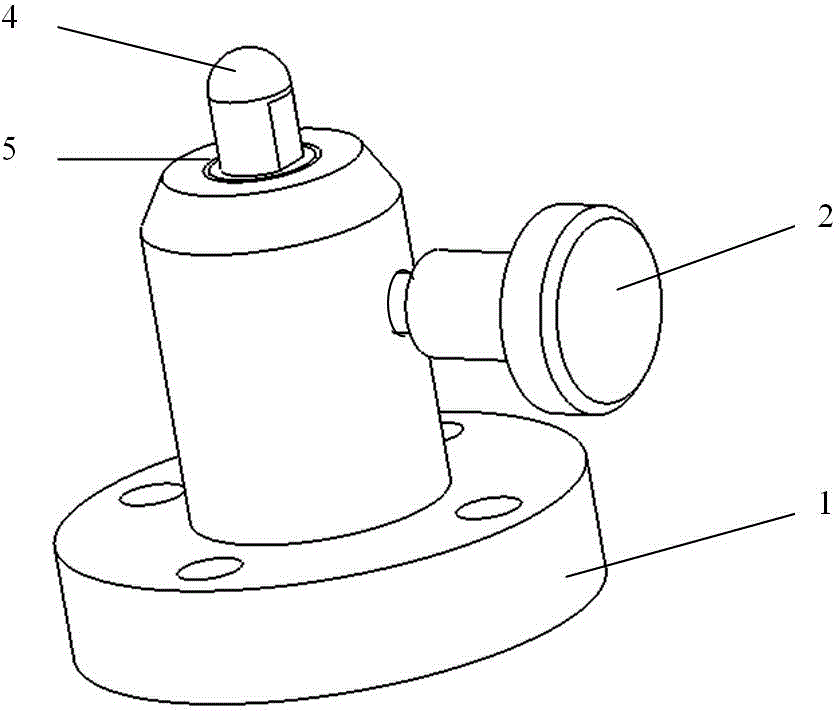

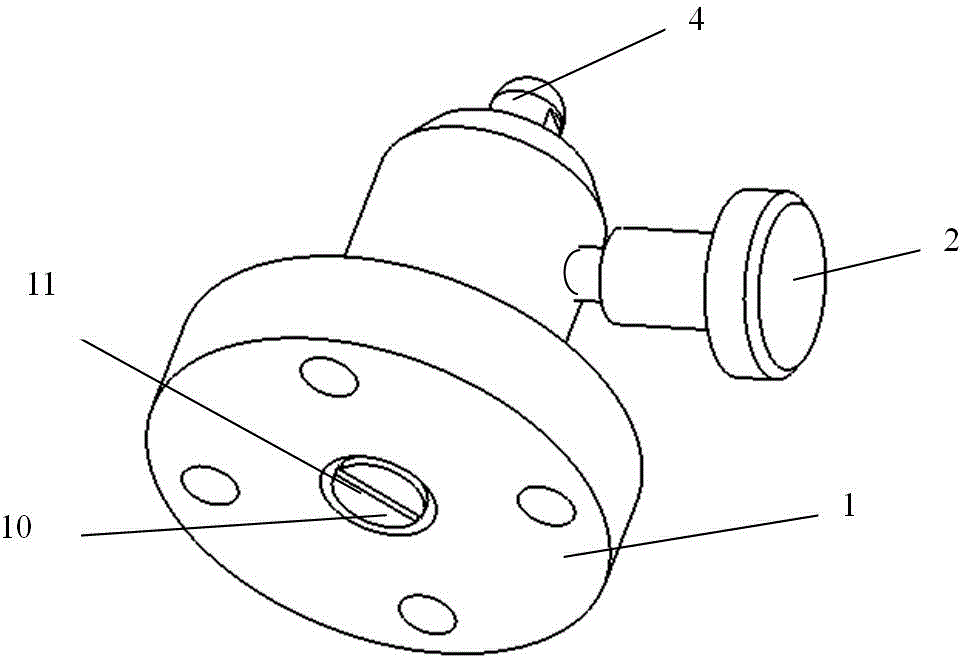

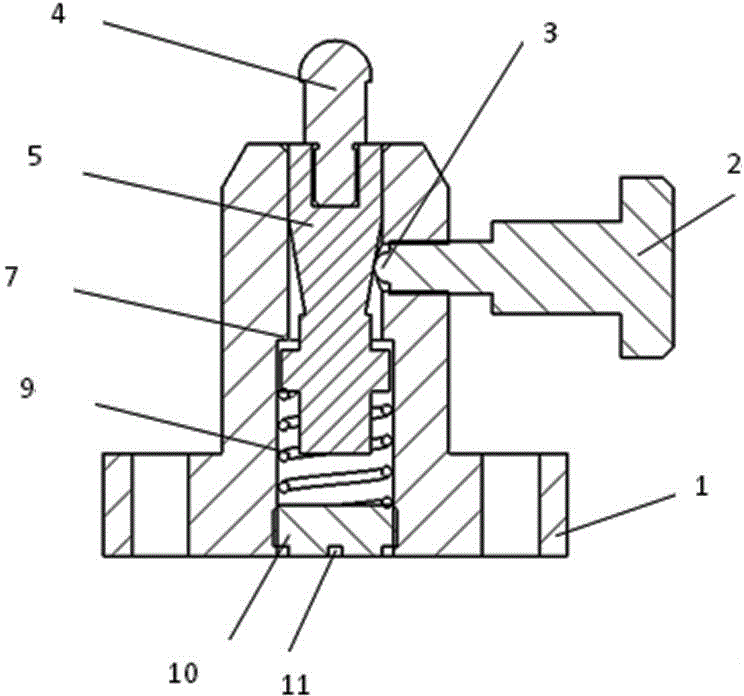

[0019] see figure 1 and figure 2 , an automatic adjustment auxiliary support mechanism for tooling molds includes a support body 1 , a lifting mechanism and a non-slip handle 2 . see image 3 , the support body 1 is columnar, with a hole in the middle of the axial direction; the lifting mechanism is located in the through hole of the support body 1 . The lifting mechanism is composed of a support column 4, a mandrel 5 and a spring 9; the support column 4 is fixedly installed on the support end of the mandrel 5, and the end of the support column 4 is a hemispherical crown head; the support column 4 on both sides of the hemispherical crown head The face is flattened; see Figure 4 , the middle part of mandrel 5 is a truncated cone with a large top and a small bottom, and an annular boss 8 is arranged on the mandrel 5 below the truncated cone;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com