Method for enabling metal insert to be moulded through injection moulding and injection product containing metal insert

A metal insert and injection molding technology, applied in the direction of coating, etc., can solve the problems of insufficient injection molding, increased production cost, limited application range, etc., and achieve the goals of avoiding insufficient injection molding or overflowing glue, simplifying the bonding structure, and simplifying the bonding structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

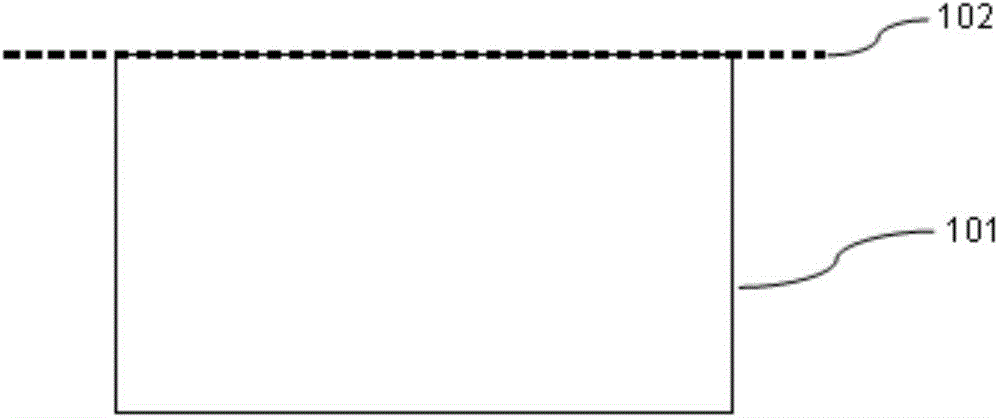

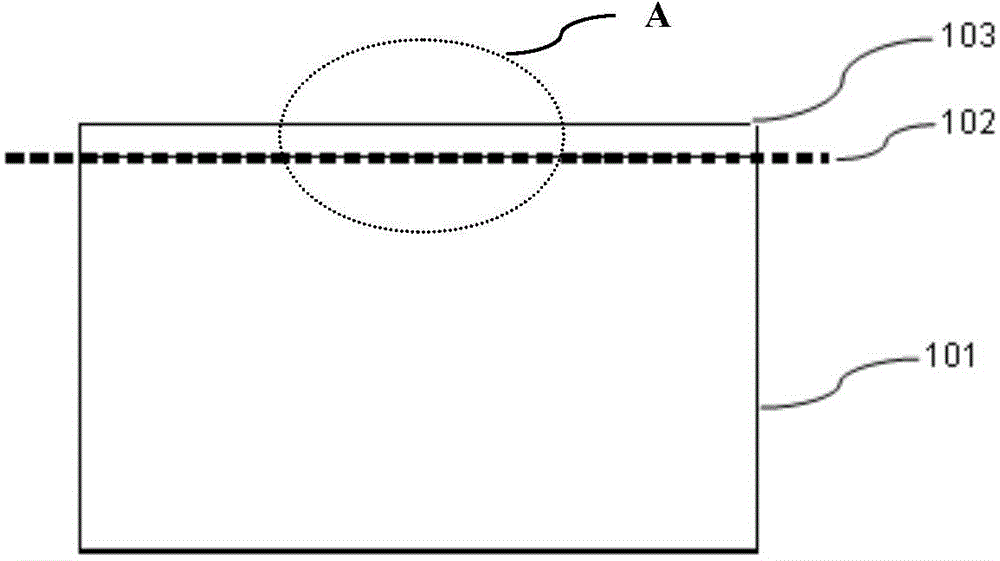

[0035] refer to Figure 1a~1c , figure 2 , the present invention provides an injection molding product of a metal insert, which includes: a metal insert 101 and a plastic 104 after surface treatment.

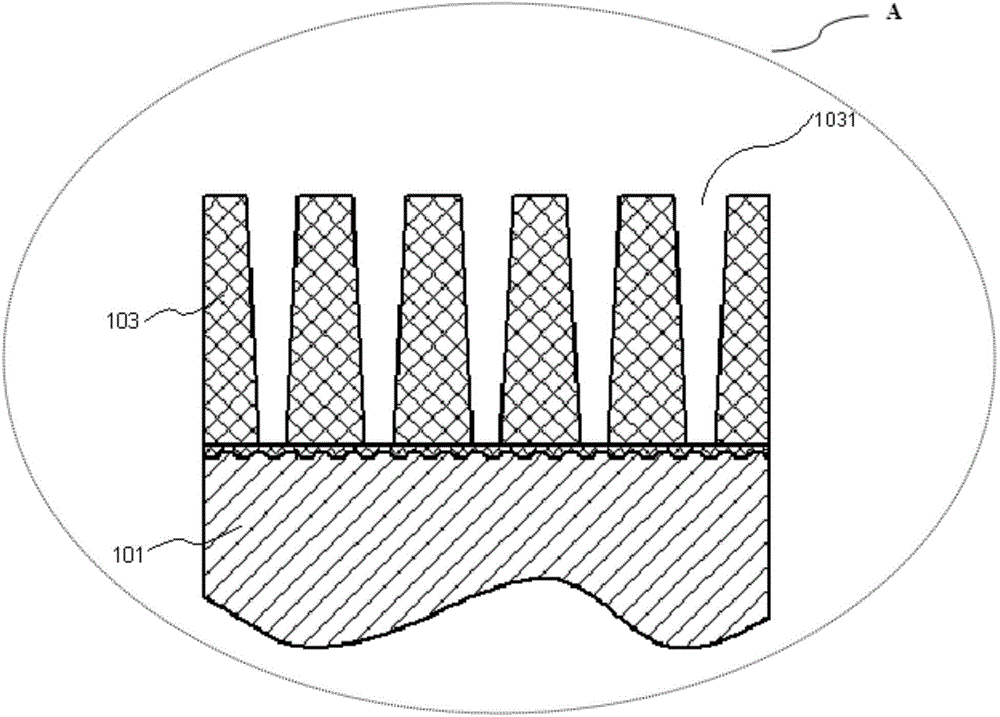

[0036] Such as Figure 1a It is a schematic diagram of the structure of the metal insert 101 without anodic oxidation treatment. The surface of the metal insert 101 is anodized to form a film layer 103 with a thickness of about 5-7 μm (refer to Figure 1b ); Figure 1c yes Figure 1b Enlarged view of part A in Fig. Such as Figure 1c As shown, the film layer 103 has a hole 1031 inside and the hole 1031 is filled with an adhesion treatment agent (not shown). The depth of the hole is 1-10 μm, and the pore diameter is 5-30 nm.

[0037] The plastic 104 is combined with the metal insert 101 , and a part of the plastic 104 enters the hole 1031 and is combined with the metal insert 101 through the adhesion treatment agent.

[0038] The injection molded product of the metal inse...

Embodiment 2

[0082] The difference between embodiment 2 and embodiment 1 is: in embodiment 2, such as image 3 As shown, the metal insert 301 of the injection molding product of the metal insert and the film layer 303 are concave on the surface at the junction to form a concave hole 3011 communicating with the hole 3031 in the film layer 303, and the concave hole 3011 is also filled with adhesion treatment agent (not shown), the plastic part continues to enter the concave hole 3011 and is combined with the metal insert 301 through the adhesion treatment agent.

[0083] In this embodiment, the difference between the manufacturing method of the injection molding product of the metal insert and Embodiment 1 is that:

[0084] Please refer to image 3 , Figure 4After performing the anodizing treatment and before performing the adhesion treatment, the metal insert 301 is also subjected to hole expansion treatment, specifically, the metal insert 301 after the anodic oxidation treatment is imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com