Self-adapted traction control drive axle differential mechanism

A traction control and differential technology, applied in the fields of differentials, adaptive traction control drive axle differentials, truck drive axles and engineering vehicle drive axles, can solve problems that cannot be reproduced, cannot be applied, and are difficult to popularize. problems, to achieve the effect of improving the utilization rate of power, strong passing ability and high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

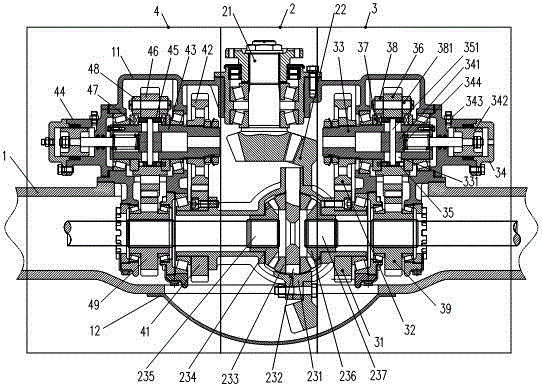

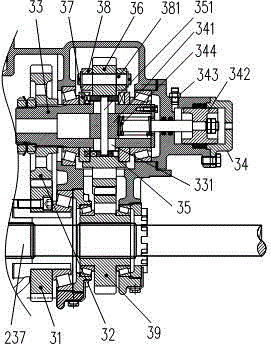

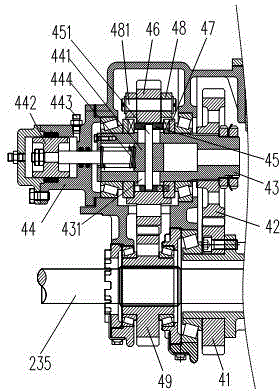

[0030] Such as Figure 1 to Figure 6 As shown, the adaptive traction control transaxle differential of the present invention consists of a fixed transaxle housing 1 and a main drop differential 2 installed in the fixed transaxle housing 1, a right drive torque regulator 3 and a left drive torque regulator 4 composition.

[0031] The fixed drive axle case 1 includes a front end cover 11 and a rear end cover 12 ; an assembly through hole 110 is provided in the middle of the front end cover 11 .

[0032] The main reducer differential 2 is composed of the main reducer driving gear 21, the main reducer passive gear 22 and the differential 23, and its driving force is directly transmitted to the wheels through the left and right drive axle shafts of the differential 23 and the left and right differential ;

[0033]The gear shaft 211 of the main deceleration driving gear 21 is a solid half shaft, the power input end passes through the assembly hole 110 of the front end cover 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com